Vi. 2 example programs, Vi. 2, Example programs – Brookfield DV-III Rheometer User Manual

Page 50

Brookfield Engineering Laboratories, Inc.

Page 50

Manual No. M/98-211-A0701

B.E.V.I.S. PROGRAM TO SLOT #1. Click on this button to download the displayed pro-

gram to the DV-III+. When the download is complete, the DV-III+ displays DOWNLOAD

DONE TO EXIT PRESS A KEY.

At this point, the program in the DV-III+ can be printed and/or run from the Rheometer.

Click on this button to exit the RheoLoader software.

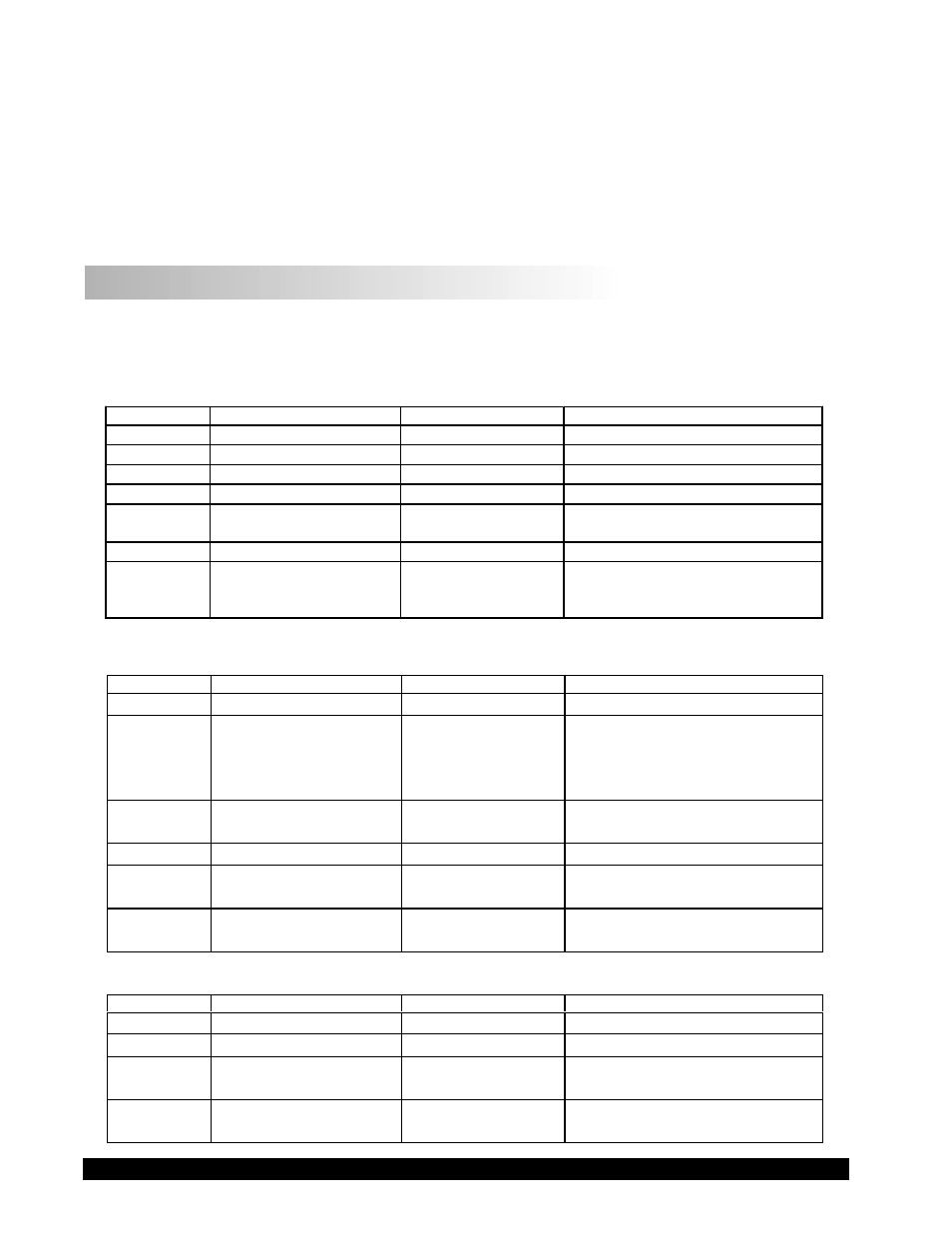

VI. 2 Example Programs

The following example programs can also be found on the RheoLoader disk that was included with

the DV-III+ Rheometer:

Program 1:

Pre-shear

Command

Command Description

Parameter

Comments

PLN

Print text now

Preshearing now

print user message

SSN

Set viscometer speed

50.0

run at 50 RPM

WPT

Wait for % torque

90.0

wait unitl 90% torque is reached

PLN

Print text now

Collecting data

print user message

SPI

Set print interval

00:10

begin printing data at 10 second

intervals

SSN

Set viscometer speed

10.0

run at 10 RPM

WTI

Wait for time interval

01:40

wait at this step for 1 minute and

40 seconds, effectively printing

10 data lines

Program 2:

For use with an external temperature controller

Command

Command Description

Parameter

Comments

STM

Set temperature

40.0

Set control value to 40°C

WTP

Wait for temperature

40.0

wait until temperature = 40°C

(as an example, a

Thermosel/Controller can be

used for temperature control)

WTI

Wait for time interval

05:00

soak time; allow temperature to

settle

SSN

Set viscometer speed

25.0

run at 25 RPM

SPI

Set print interval

00:30

begin printing data at 30 second

intervals

WTI

Wait for time interval

06:00

wait at this step for 6 minutes,

effectively printing 12 data lines

Program 3:

Wait for cure

Command

Command Description

Parameter

Comments

SSP

Set spindle

31

set to a number 31 spindle

SSN

Set viscomter speed

100.0

run at 100 RPM

SPI

Set print interval

00:05

begin printing data at 5 second

intervals

WPT

Wait for % torque

85.0

wait until % torque = 85; a

curing cycle