V.6 timed data collection, Timed data collection – Brookfield DV-III Rheometer User Manual

Page 44

Brookfield Engineering Laboratories, Inc.

Page 44

Manual No. M/98-211-A0701

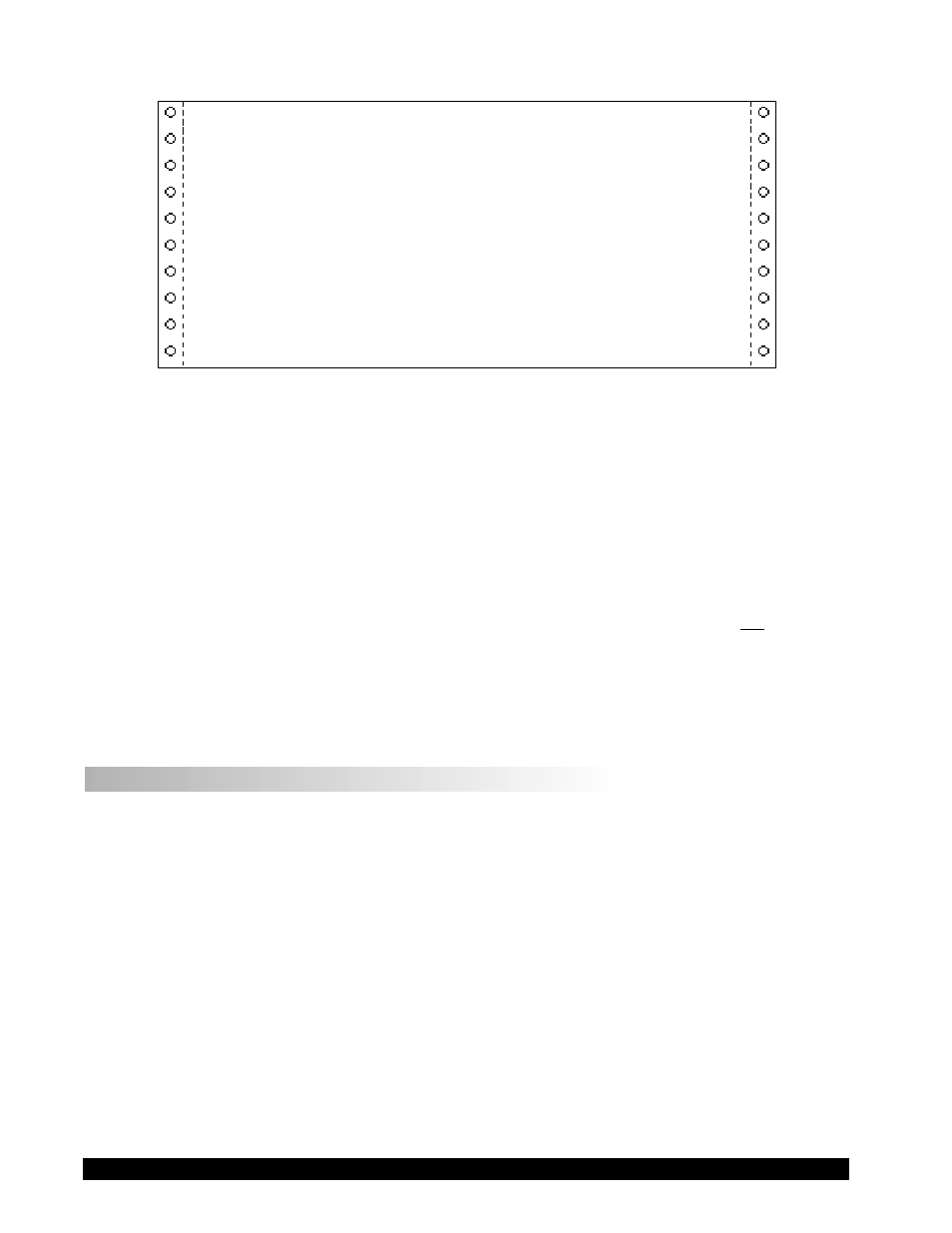

Sample Name:_____________________________________________________________

Operater Name:____________________________

Date: 06/21/91 Time: 10:06 Model: 2R Spindle: 31

#01 RPM=30.0 %=18.2 cP=970 D/CM2=100 1/SEC=10.2 T=22.1C TIME=00:05

#02 RPM=40.0 %=24.3 cP=972 D/CM2=132 1/SEC=13.6 T=22.1C TIME=00:05

#03 RPM=50.0 %=30.3 cP=969 D/CM2=164 1/SEC=17.0 T=22.1C TIME=00:05

#04 RPM=60.0 %=36.3 cP=967 D/CM2=197 1/SEC=20.4 T=22.1C TIME=00:05

#05 RPM=70.0 %=42.3 cP=966 D/CM2=230 1/SEC=23.8 T=22.1C TIME=00:05

Figure 64

Review data notes:

1) The DV-III+ stores data from the most recent speed set program test. When a subsequent

speed set program is run, any test data in memory will be overwritten and the previous

data will be lost.

2) If the “Printer Only” option is selected, the date, time of day, model and spindle number

are printed with the test results. The DV-III+ does not store time and date when it is turned

off; therefore, the time and date must be entered when printing the first time after start-

up. See Section V.2.

3) The DV-III+ may be set-up to “handshake” (using XOn/XOff protocol) or not handshake

when connected to a serial printer. If you opt to use the handshake mode, your printer is

“on line”, all cable connections are correct and your printer is set for handshake mode,

then data should appear on your printer immediately. If it does not appear, and instead

you see the message:

“PRINTER IS NOT READY TURN ON/PRESS ONLINE”

then you should

turn the handshake option off. See Section V.2.

V.6 TIMED DATA COLLECTION

The DV-III+ offers three methods of time control that may be used independently of control

programs. These techniques result in a single data point collected at the end of the test. If multiple

points are required, the rheometer should be connected to a printer and set up with an appropriate

print interval.

TIME TO TORQUE

The DV-III+ will record the amount of time required to reach the specified % torque value at a single

speed. Torque and speed are input using the number keys and

OPTIONS/TAB

key. The test will begin

immediately upon the press of the

ENTER

key.

The test will end when the specified torque level is reached (in either an upward or downward

direction). The data will be displayed as shown in Figure 65. The

SELECT DISPLAY

key can be used

to view all measurement parameters. The

key can be used to send a single data line to the

printer.