Brookfield DV2T Viscometer User Manual

Page 60

Brookfield Engineering Labs., Inc.

Page 60

Manual No. M13-167-B0614

A.3 Setting the Gap

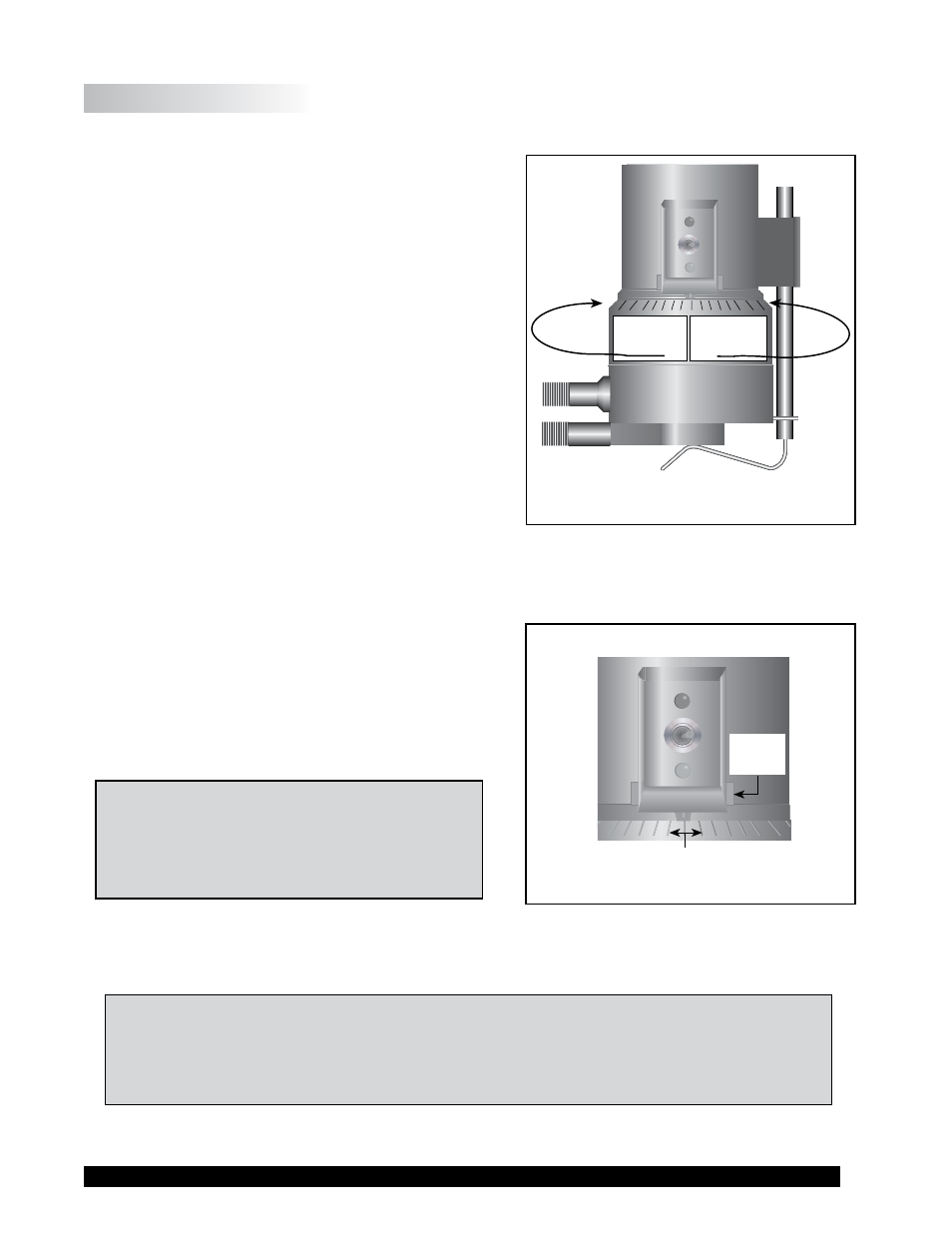

1. Move the toggle switch to the right; this will turn

on (enable) the Gap Setting Feature. The Pilot

(red) light will be illuminated.

Note: The motor should be OFF.

2. If the contact light (yellow) is illuminated, turn

the micrometer adjustment ring clockwise (as

you look down on the instrument) until the light

is no longer illuminated (see Figure A-5).

3. If the yellow contact light is not illuminated,

slowly

turn the micrometer adjustment ring in

small increments (one or two scale divisions)

counter-clockwise.

Continue moving the micrometer adjustment

ring slowly

counter-clockwise until the contact

light (yellow) first turns on. THIS IS THE “HIT

POINT

.”

4. Adjust the sliding reference marker, right or

left, to the closest full scale division mark (see

Figure A-6).

5. Turn the micrometer adjustment ring one scale

division to the left to meet the line on the sliding

reference marker. THE YELLOW CONTACT

LIGHT SHOULD GO OFF.

6. You have established the gap space needed

for measurement. Now turn the toggle switch

OFF (left); the red pilot light should go off.

The viscosity of electrically conductive fluids

may be affected if readings are taken with

the Electronic Gap Setting feature “on”. Be

sure to shut the feature “off” before taking

readings!

7. Carefully remove the sample cup.

Note

:

1. The cup may be removed and replaced without resetting the gap if the micrometer

adjustment ring has not been moved.

2. Remove the spindle from the viscometer when cleaning.

3. Re-establish the hit point every time the spindle is attached/detached.

Moves Away

from Hit Point

(clockwise)

LEFT

x

Moves Towards

Hit Point

(counter-clockwise)

RIGHT

Full Scale

Division Marks

Sliding

Reference

Marker

Figure A-5

Figure A-6