Brookfield DV2T Viscometer User Manual

Page 24

Brookfield Engineering Labs., Inc.

Page 24

Manual No. M13-167-B0614

Many samples must be controlled to a specific temperature for viscosity measurement.

When conditioning a sample for temperature, be sure to temperature control the

container and spindle as well as the sample.

Please see our publication, “More Solutions to Sticky Problems”, for more detail relating

to sample preparation.

III.3 Selecting a Spindle/Speed

The DV2T has the capability of measuring viscosity over an extremely wide range. For

example, the DV2TRV can measure fluids within the range of 100-40,000,000 cP. This

range is achieved through the use of several spindles over many speeds. See Appendix

B for details.

The process of selecting a spindle and speed for an unknown fluid is normally trial and

error. An appropriate selection will result in measurements made between 10-100 on

the instrument % torque scale.

Two general rules will help in the trial and error process.

1) Viscosity range is inversely proportional to the size of the spindle.

2) Viscosity range is inversely proportional to the rotational speed.

In other words: to measure high viscosity, choose a small spindle and/or a slow speed.

If the chosen spindle/speed results in a reading above 100%, then reduce the speed or

choose a smaller spindle.

Experimentation may reveal that several spindle/speed combinations will produce satisfactory

results between 10-100%. When this circumstance occurs, any of the spindles may be

selected.

Non-Newtonian fluid behavior can result in the measured viscosity and yield stress changing

if the spindle and/or speed is changed. See our publication, “More Solutions to Sticky

Problems”, for more details.

When viscosity data must be compared, be sure to use

the same test methodology: namely the same instrument,

spindle, speed, container, temperature and test time.

DV2TLV Viscometers are provided with a set of four spindles

and a narrow guardleg; DV2TRV Viscometers come with a set

of six spindles and a wider guardleg; DV2THA and DV2THB

Viscometers come with a set of six spindles and no guardleg.

(See Appendix G for more information on the guardleg.)

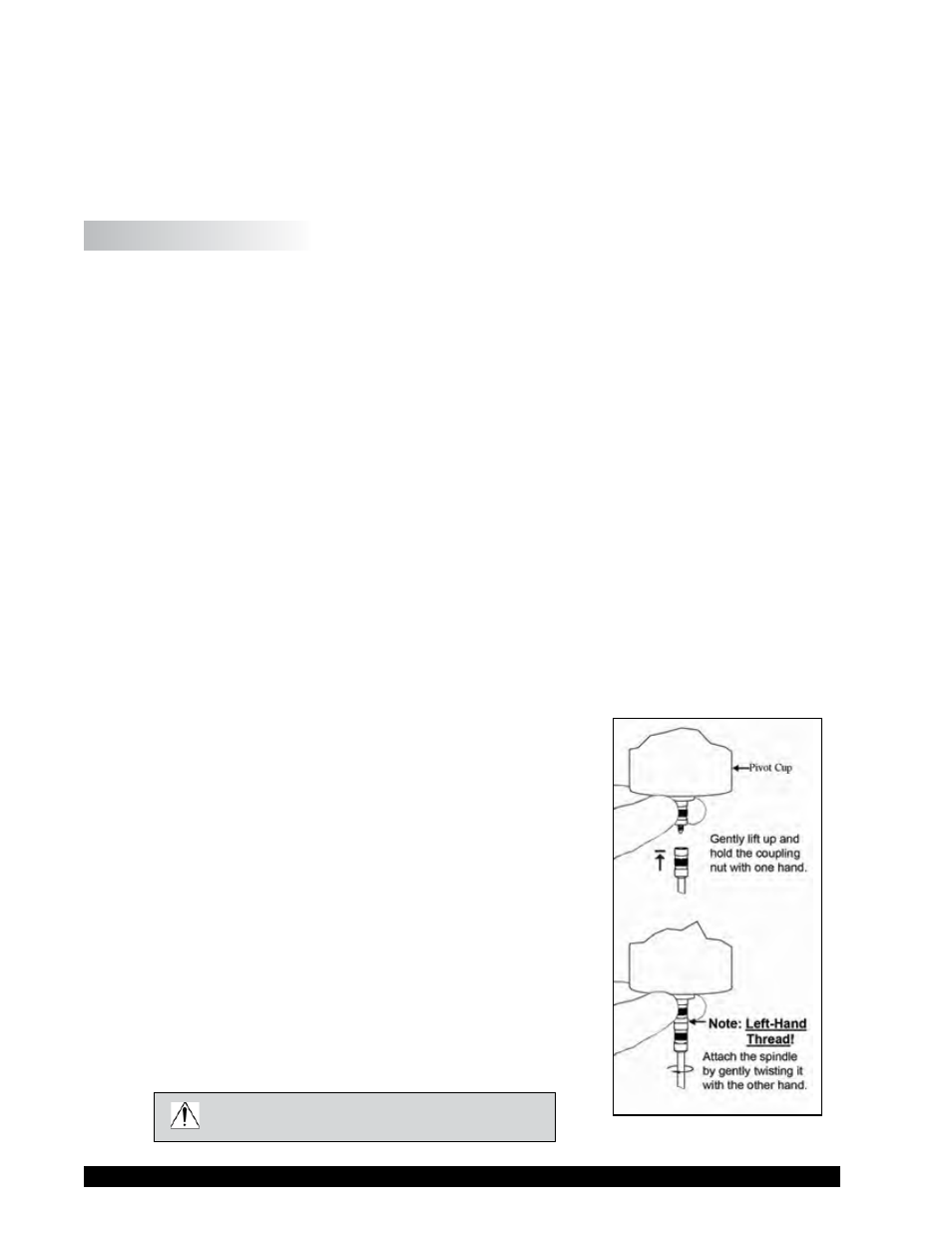

The spindles are attached to the viscometer by screwing

them onto the coupling nut on the lower shaft (see Figure

III-1). Note that the spindles have a left-hand thread. The

lower shaft should be secured and slightly lifted with one hand

while screwing the spindle to the left. The face of the spindle

nut and the matching surface on the lower shaft should be

smooth and clean to prevent eccentric rotation of the spindle.

Spindles can be identified by the number on the side of the

spindle coupling nut.

The motor should be OFF whenever

spindles are being removed or attached.

Figure III-1