Appendix a - cone/plate viscometer set-up – Brookfield DV2T Viscometer User Manual

Page 58

Brookfield Engineering Labs., Inc.

Page 58

Manual No. M13-167-B0614

Appendix A - Cone/Plate Viscometer Set-Up

This Cone/Plate version of the DV2T uses the same operating instruction procedures as

described in this manual. However, the “gap” between the cone and the plate must be verified/

adjusted before measurements are made. This is done by moving the plate (built into the

sample cup) up towards the cone until the pin in the center of the cone touches the surface

of the plate, and then by separating (lowering) the plate 0.0005 inch (0.013 mm).

When operating the Cone/Plate at elevated temperature, the gap must be set with the cup

and spindle equilibrated at the temperature recommended. Maximum temperature for Cone/

Plate operation is 80ºC. Maximum operational temperature of sample cup is 100

ºC.

Personal

protection is recommended when controlling to temperatures above 80ºC.

Note

: Micrometer Adjustment Ring will become hot when controlling sample

cup at temperatures above 50ºC.

Programmable DV2T Cone/Plate Viscometers, S/N 50969 and higher, have an Electronic Gap

Setting feature. This feature enables the user to easily find the 0.0005 inch gap setting that

was established at Brookfield prior to shipment.

Brookfield recommends that the maximum particle size in the sample material for measurement

with cone/plate geometry be less than 5 times the gap setting. A more conservative approach

is to limit the maximum particle size to less than 10 times the gap setting.

The following information explains how to set the Electronic Gap and verify calibration of the

DV2T Viscometer.

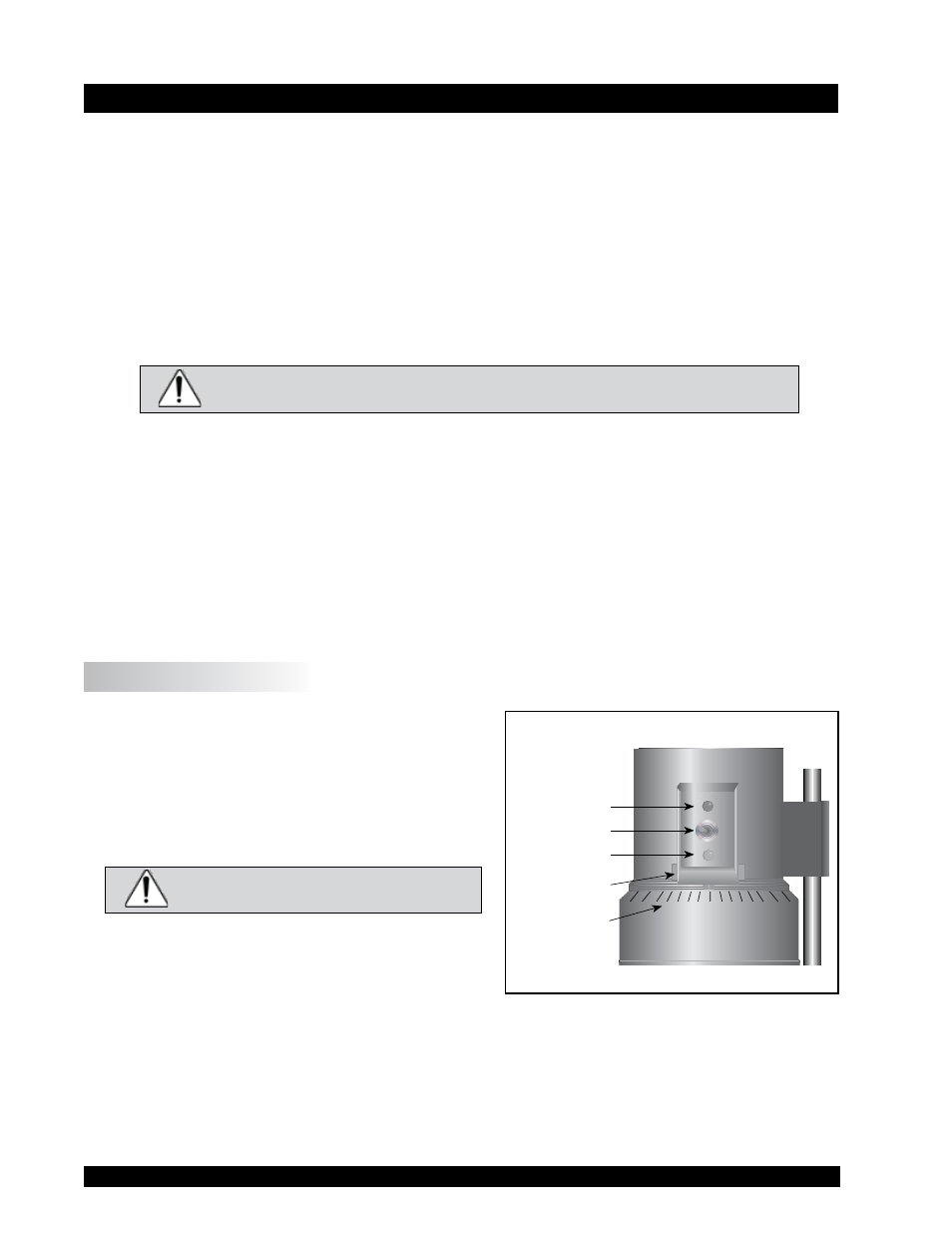

A.1 Electronic Gap Setting Features

TOGGLE SWITCH

allows you to enable/disable the

Electronic Gap Setting Feature: left position is

OFF (disabled), right position is ON (enabled).

PILOT LIGHT

is the red (LED) light; when illuminated,

it means the Electronic Setting Function is

sensing (enabled).

Note

: Be sure the light is off before

introducing the test sample.

CONTACT LIGHT

is the yellow (LED) light; when it

first turns on, the “hit point” has been found.

SLIDING REFERENCE MARKER

is used after finding the

“hit point;” it is the reference for establishing the

0.0005 inch gap.

MICROMETER ADJUSTMENT RING

is used to move the cup up or down in relation to the cone

spindle. Turning the ring left (clockwise) lowers the cup; turning it right (counterclockwise)

raises the cup. Each line on the ring represents one scale division and is equivalent to

0.0005 inch movement of the plate relative to the cone.

Pilot Light

(red)

Toggle Swtich

Contact Light

(yellow)

Sliding Reference

Marker

Micrometer

Adjustment Ring

Figure A-1