Carrier OMNIZONE 50BV020-064 User Manual

Page 3

3

INSTALLATION

Omnizone™ 50BV units are intended for indoor installa-

tion only. Determine building alterations required to run piping,

wiring, and ductwork. Read all installation instructions before

installing the unit.

Step 1 — Complete Pre-Installation Checks

EXAMINE THE UNIT — Examine the unit for shipping

damage. File a claim with the transit company if damage is

found. Check the shipment for completeness. Verify that the

nameplate electrical requirements match the available power

supply.

UNIT STORAGE — The 50BV units are designed and pack-

aged for indoor storage and use only. If the equipment is not

needed for immediate installation upon its arrival at the job site,

it should be left in its shipping carton and stored in a clean, dry

area. Units must only be stored or moved in the normal upright

position, as indicated by the “UP” arrows on each carton, at all

times. DO NOT STACK UNITS.

MODULAR UNITS — The 50BVT,U,V,W,X units are shipped

in multiple sections for easy movement and installation. The

separate modules will pass through a standard 36-in. steel-

framed door or service elevator. Circuit integrity is maintained

because none of the refrigerant piping requires disconnection.

Water piping connections are made with the use of heavy-duty

bronze-bodied unions so no field welding or brazing is required.

See Table 2 for the number of sections per unit.

Table 2 — Modular Unit Shipping Table

NOTE: Units ship with the main air conditioning, economizer/

filter, and, when selected, the reheat coil sections assembled

together. These can be easily disassembled, as required, in the

field. The fan section(s) always ships separately.

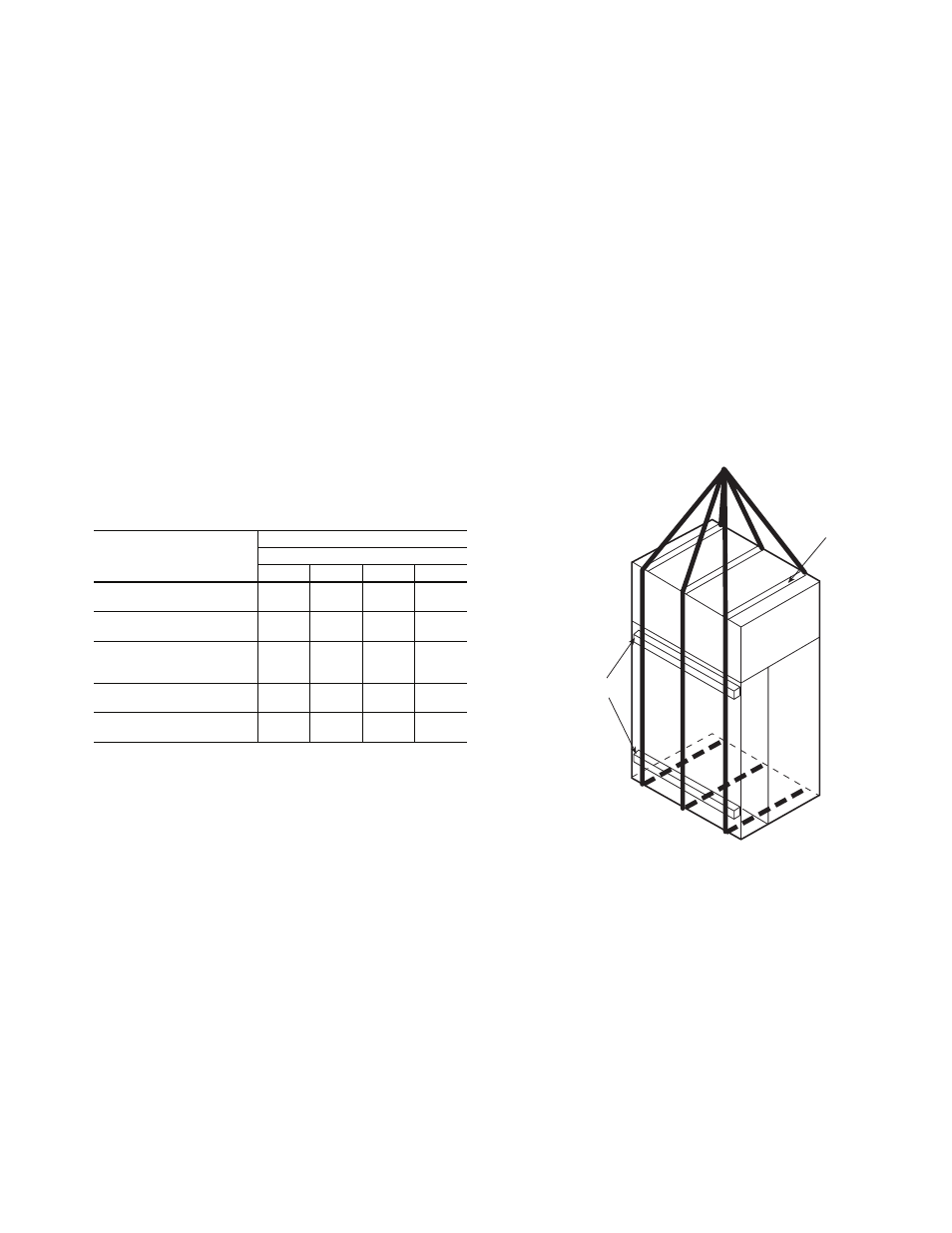

Step 2 — Rig and Place Unit —

Use proper lifting

and handling practices to avoid damage to the unit. Move

modular units with a fork truck using the baserails provided, or

use spreader bars and lifting straps as shown in Fig. 1.

For single piece units, use spreader bars and rigging straps if

lifting with a crane to avoid damage to the unit. Otherwise,

move with a fork truck using the shipping pallet.

Refer to Fig. 2-14

for unit dimensions.

Refer to Tables 3A and 3B for physical data.

REMOVE PACKAGING — Remove all protective plastic,

remove and discard unit top cover protector, filter cover,

controller display protector, and water piping connection

packaging.

UNIT LOCATION — Locate the unit in an indoor area

that allows easy removal of the filters, access panels, and

accessories. Make certain enough space is available for service

personnel to perform maintenance or repairs. Provide sufficient

room to make all water, duct, and electrical connections. If the

unit is located in a small mechanical equipment room, make

sure adequate space is available for air to return freely to the

unit. These units are not approved for outdoor installations and

must be installed inside the structure. Do not locate in areas

that are subject to freezing.

UNIT PLACEMENT — Ensure that the floor is structurally

strong enough to support the weight of the equipment with

minimum deflection. A good, level floor is required for proper

unit operation and to ensure proper fit-up and alignment of all

bolt together and union coupled modules on modular units.

SECTIONS

NUMBER OF SECTIONS

50BVT, U, V, W, X

034

044

054

064

Main Air Conditioning

Weight (lb) (each)

1

2100

2

1825

2

2200

2

2225

Reheat Coil Option

Weight (lb) (each)

1

40

2

40

2

40

2

40

Economizer/Filter

Filter Section Weight (lb)

Economizer Weight (lb)

1

310

200

2

310

200

2

310

200

2

310

200

Fan Section

Weight (lb) (each)

1

650

2

650

2

650

2

650

Total Unit

Weight (lb)

4

3300

8

5400

8

6150

8

6150

USE

SPREADER

BAR TO

PREVENT

DAMAGE

TO UNIT

4 X 4 ABOVE

AND BELOW

RETURN DUCT

CONNECTIONS

Fig. 1 — Modular Unit Rigging

a50-7257ef