Carrier OMNIZONE 50BV020-064 User Manual

Page 19

19

ACOUSTICAL CONSIDERATIONS — Proper acoustical

considerations are a critical part of every system’s design and

operation. Each system design and installation should be

reviewed for its own unique requirements. For job specific

requirements, contact an acoustical consultant for guidance and

recommendations.

In general, to reduce noise, consider the following:

• Locate mechanical room and ducts away from noise

sensitive locations. Whenever possible, work with the

architect to locate the equipment rooms around the

perimeters of restrooms, hallways, fire escapes, stair

wells, etc., to reduce noise transmission. This allows not

only for isolation from radiated sound but also enables

the contractor to route duct systems around sensitive

locations.

• Construct the equipment room of concrete block or use a

double offset stud wall with interwoven insulation. Seal

all penetrations.

• Design the system for low total static pressure.

• Use suitable vibration isolation pads or isolation springs

according to the design engineer's specifications.

• A flexible canvas duct connector is recommended on

both the supply and return air sides of units to be

connected to system ductwork.

• Use a minimum of 15 ft of return ductwork between the

last air terminal or diffuser and the unit.

• Insulate supply and return ducts with 2-in., 3-lb density

insulation.

• Round duct is recommended. If rectangular ductwork is

used, keep aspect ratios as small as possible (i.e., as close

to square as possible).

• Avoid any direct line of sight from return air grilles

into the unit's return. If return air is to be ducted to an

equipment room, an elbow should be installed within the

equipment room.

• Running a return air drop to near the floor of the room

will aid in sound attenuation.

• Do not exceed the recommended supply duct velocity of

2,000 fpm.

• Do not exceed the recommended return duct velocity of

1,000 fpm.

• Use turning vanes on 90-degree elbows.

• Place isolation springs under each corner and under each

compressor if utilized.

ASSEMBLING MODULAR UNITS — 50BVT,U,V,W,X

30 to 60 ton units ship in the number of pieces shown in Table

2. Reassemble the unit. Use the loose hardware provided in the

main air-conditioning section and the instructions below.

1. The filter/economizer section ships bolted to the main air-

conditioning section and can be removed in the field.

When reattaching the filter/economizer section to the

main air-conditioning section, place the filter side of the

filter/economizer section facing out and away from the

main air conditioning section.

2. If the unit has 2 filter/economizer and 2 main air-

conditioning sections (40 through 60 ton units), bolt the

remaining filter/economizer section and main air-

conditioning section together, as in Step 1.

3. For units with 2 filter/economizer and 2 main air-

conditioning sections, use the provided unions to assem-

ble the water connections between the 2 additional

sections joined in Step 2.

4. For units with multiple air conditioning sections, connect

the condensate drain hoses from the “B” side of the unit

to the drain manifold on the “A” side of the unit.

5. For unit sizes 044-064, connect power wiring from the

main terminal block in the “A” side of the unit to the

power terminal block in the “B” side of the unit.

6. For VAV units only, connect the plenum tubing, coiled

behind the VAV control panel, to the bulkhead fittings

located in the discharge of the supply fan. This connects

the high pressure supply to the high side of the duct high

static pressure switch.

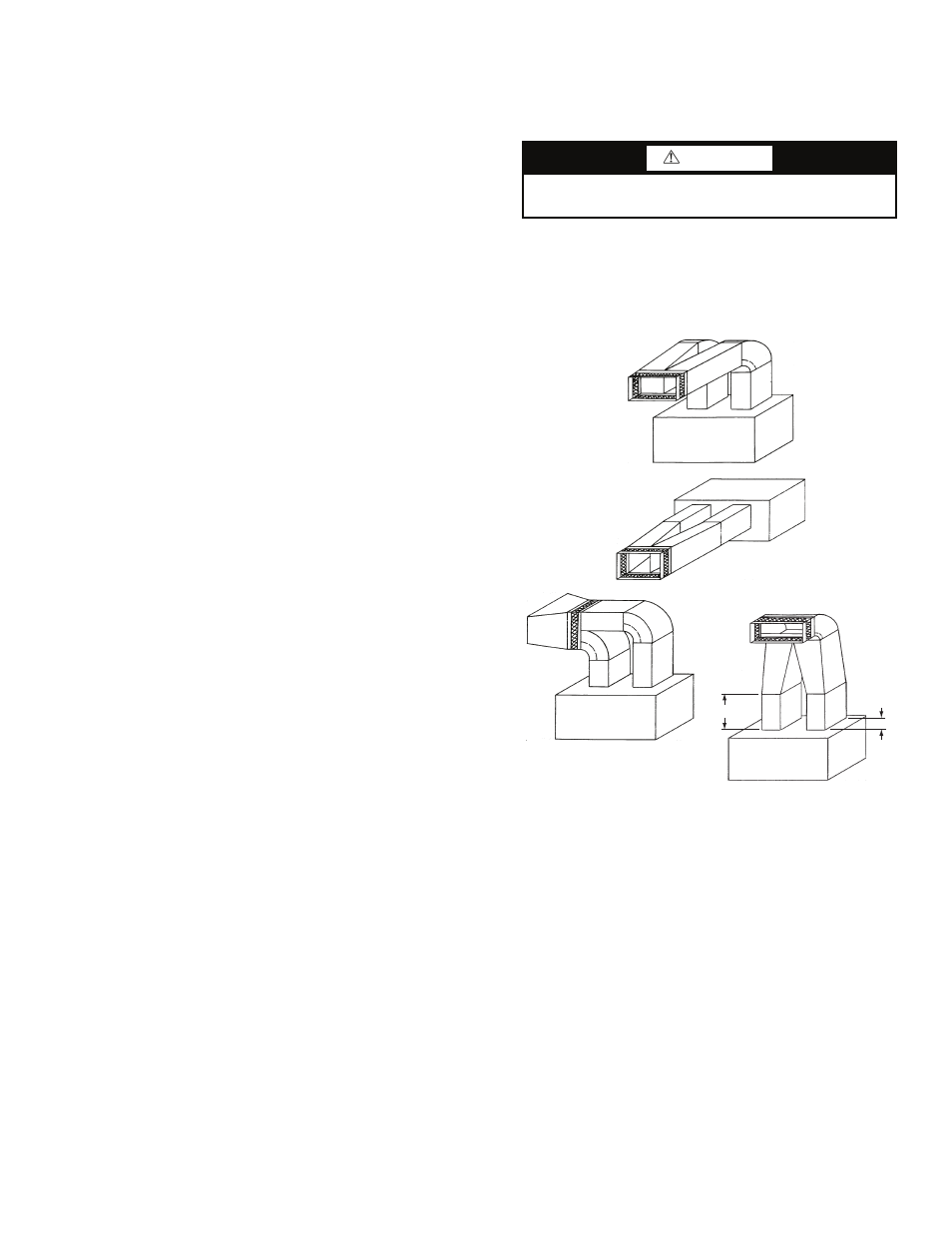

Step 3 — Install Ductwork —

The VAV units must

use a “pair of pants” configuration as shown in Fig. 15. Refer

to the Carrier System Design Manual or ASHRAE (American

Society of Heating, Refrigerating and Air Conditioning Engi-

neers) standards for the recommended duct connection to unit

with 2 fans.

A supply air outlet collar and return air duct flange are pro-

vided on all units to facilitate duct connections. Refer to dimen-

sional drawings (Fig. 2-14) for connection sizes and locations.

A flexible canvas duct connector is recommended on both

supply and return air sides of the units to be connected to the

system ductwork.

All metal ductwork should be adequately insulated to avoid

heat loss or gain and to prevent condensation from forming on

the duct walls. Uninsulated ductwork is not recommended, as

the unit's performance will be adversely affected.

Do not connect discharge ducts directly to the blower

outlet(s). The factory filter should be left in place on a free

return system.

If the unit will be installed in a new installation, the duct

system should be designed in accordance with the System De-

sign Manual, Part 2 and with ASHRAE (American Society of

Heating, Refrigeration and Air Conditioning Engineers) proce-

dures for duct sizing. If the unit will be connected to an existing

duct system, check that the existing duct system has the capaci-

ty to handle the required airflow for the unit application at an

CAUTION

Remove all shipping blocks, if any, under blower housing

or damage to the fan may occur.

Fig. 15 — Typical Fan Discharge Connections for

Multiple Fan Units

NOTE: A = 1

1

/

2

to 2

1

/

2

B

A

B

a50-8357.eps