Table 5b — condenser pressure drop 50bvt,v,w units – Carrier OMNIZONE 50BV020-064 User Manual

Page 22

22

Table 5A — Condenser Pressure Drop

50BVC,J,Q Units

LEGEND

Table 5B — Condenser Pressure Drop

50BVT,V,W Units

LEGEND

Pressure and temperature ports are recommended in both

the supply and return lines for system flow balancing. These

openings should be 5 to 10 pipe diameters from the unit water

connections. For thorough mixing and temperature stabiliza-

tion, wells in the water piping should extend at least

1

/

2

pipe

diameter into the pipe. Measuring the condenser waterside

pressure drop and referring to Tables 5A and 5B can help to

properly set the water flow rate.

Improper fluid flow due to valving, piping, or improper

pump operation constitutes abuse that may result in voiding of

unit warranty. The manufacturer will not be responsible for

damages or failures resulting from improper piping design or

piping material selection.

EVAPORATOR CONDENSATE DRAIN — The condensate

drain connection is 1

1

/

4

-in. FPT and is located on the same side

of the unit as the condenser water connections. See dimension

drawings (Fig. 2-14) for exact location.

Drain lines should be pitched away from the unit with a

minimum slope of

1

/

8

-in. per foot and conform to all local and

national codes.

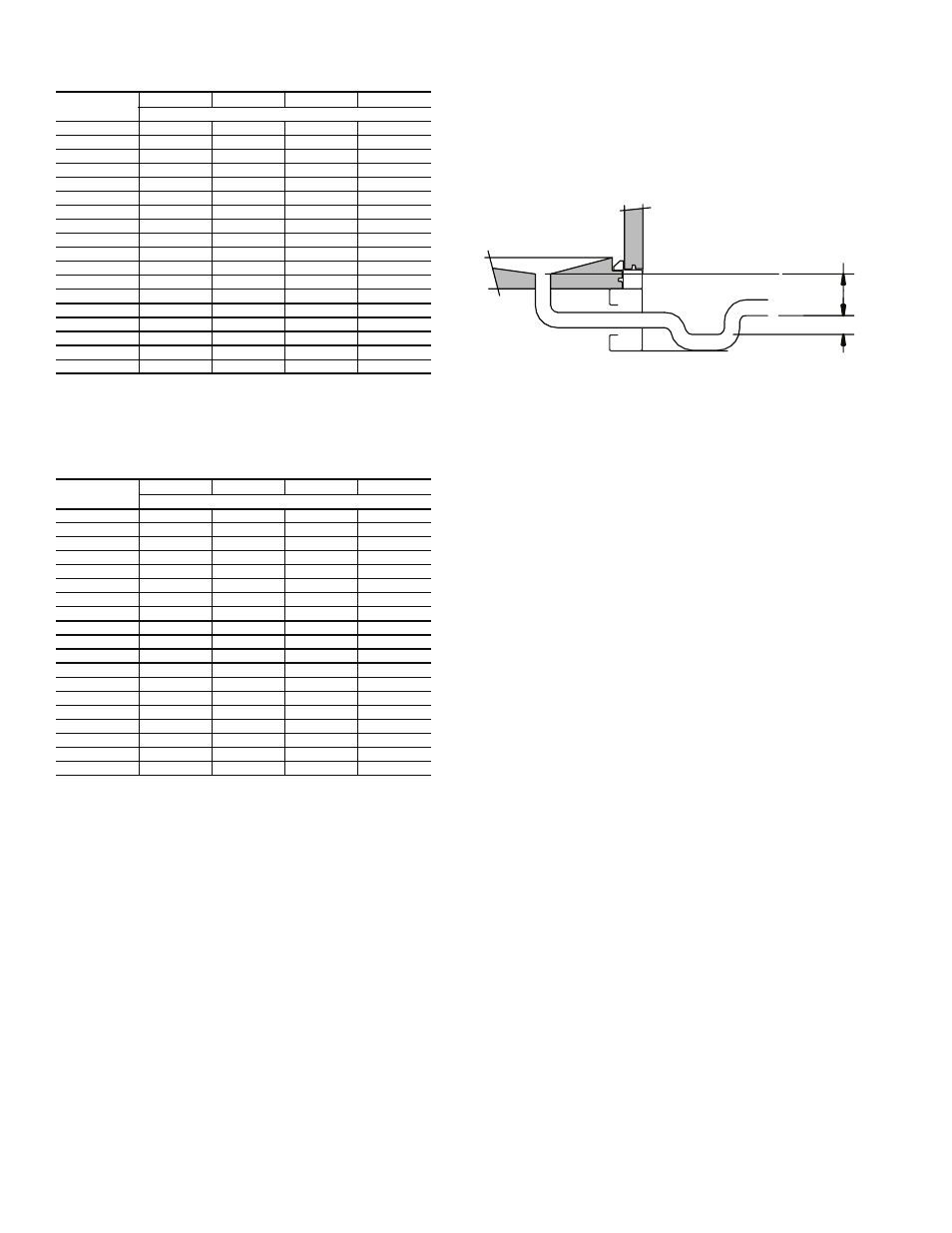

A trap must be installed in the condensate line to ensure free

condensate flow (units are not internally trapped). A vertical air

vent is sometimes required to avoid air pockets.

Install a condensate-trapping drain line at the units drain

connection. See Fig.

20 for correct drain layout.

When calculating trap depth, remember that it is not the

total static pressure but the upstream or downstream static

resistance that is trapped against. For instance, when calculat-

ing the trap depth for a cooling coil condensate pan, trap

against the coil pressure drop in that coil section and any other

pressure drops upstream of it.

If calculating the trap depth for the cooling coil, use the total

static pressure drop (coil plus any other components upstream

of it) plus 1 in. (P

1

= negative static pressure + 1 in.), as shown

in Fig. 21.

Traps must store enough condensate to prevent losing the

drain seal at start-up. The “Minimum

1

/

2

P

1

” dimension ensures

that enough condensate is stored.

Drain pans should be cleaned periodically to avoid the

build-up of dirt and bacterial growth.

HOT WATER HEATING COIL (Optional) — A factory-installed

one or 2-row hot water heating coil is available as an option. The

coil is supplied with hot water from a boiler through separate pip-

ing from the condenser water loop. All controls for heating opera-

tion are field-supplied.

Piping should be in accordance with accepted industry

standards and all components rated for the system pressure

expected. Pipe the coils so that they will drain, and provide a

drain and vent.

Always connect the supply to the top of the coil, and the

return to the bottom. Refer to Fig. 2-14 for hot water supply

and return piping locations.

Water coils should not be subjected to entering air tempera-

tures below 38 F to prevent coil freeze-up. If air temperatures

across the coil are going to be below this value, use a glycol or

brine solution. Use a solution with the lowest concentration

that will match the coldest air expected. Excess concentrations

will greatly reduce coil capacity.

The return air duct system should be carefully designed to

get adequate mixing of the return air and outdoor air streams to

prevent cold spots on the coil that could freeze.

A 2 or 3-way, field-supplied modulating control valve, or a

simple 2-position on-off valve may be used to control water

flow. Select the valve based on the control valve manufacturer's

recommendations for size and temperature rating. Select the

control valve CV based on pressure drop and flow rate through

the coil. This information is available from the VPACBuilder

software program or Tables 6A and 6B.

FLOW RATE

(gpm)

SIZE 020

SIZE 024

SIZE 028

SIZE 034

Pressure Drop (ft wg)

35

9.1

—

—

—

40

11.2

6.0

—

—

45

13.5

7.5

—

—

50

15.9

9.1

9.1

—

55

18.4

10.9

10.9

—

60

21.1

12.8

12.8

10.8

65

23.9

14.8

14.9

12.7

70

27.4

17.0

17.2

14.7

75

—

19.3

19.6

16.9

80

—

21.7

22.2

19.2

85

—

—

24.9

21.7

90

—

—

27.8

24.3

95

—

—

30.8

27.1

100

—

—

34.0

30.0

105

—

—

—

33.1

110

—

—

—

36.3

115

—

—

—

39.7

120

—

—

—

43.2

GPM — Flow Rate

PD

— Pressure Drop (ft wg)

FLOW RATE

(gpm)

SIZE 034

SIZE 044

SIZE 054

SIZE 064

Pressure Drop (ft wg)

60

8.7

—

—

—

70

11.9

—

—

—

80

15.5

6.3

—

—

90

19.6

8.0

—

—

100

24.2

9.9

6.0

—

110

29.3

12.0

7.3

—

120

34.9

14.3

8.7

8.7

130

—

16.7

10.2

10.2

140

—

19.4

11.8

11.8

150

—

22.3

13.6

13.6

160

—

25.3

15.5

15.5

170

—

—

17.4

17.4

180

—

—

19.6

19.6

190

—

—

21.8

21.8

200

—

—

24.2

24.2

210

—

—

—

26.6

220

—

—

—

29.2

230

—

—

—

31.9

240

—

—

—

34.8

GPM — Flow Rate

PD

— Pressure Drop (ft wg)

1/2

P

1

P

1

Fig. 20 — Condensate Drain Layout

a39-2371ef