Installation, Parallel assembly – Pilz PSEN cs4.1a User Manual

Page 14

PSEN cs4.1a/b/p/M12

Operating Manual PSEN cs4.1a/b/p/M12

22187-EN-02

14

Installation

}

The safety switch and actuator should be installed opposite each other in parallel.

CAUTION!

The unit's properties may be affected if installed in an environment contain-

ing electrically or magnetically conductive material. Please check the oper-

ating distances and the assured release distance.

}

Safety switches and actuators should only be secured using M4 screws with a flat head

(e.g. M4 cheese-head or pan head screws).

}

The actuator should be protected from unauthorised removal and from contamination.

Close the mounting holes using the seals provided.

}

Torque setting: Max. 0.8 Nm.

}

The distance between two safety switches must be maintained (see

).

Safety switches and actuators

}

Should not be exposed to heavy shock or vibration and

}

Should not be used as a limit stop.

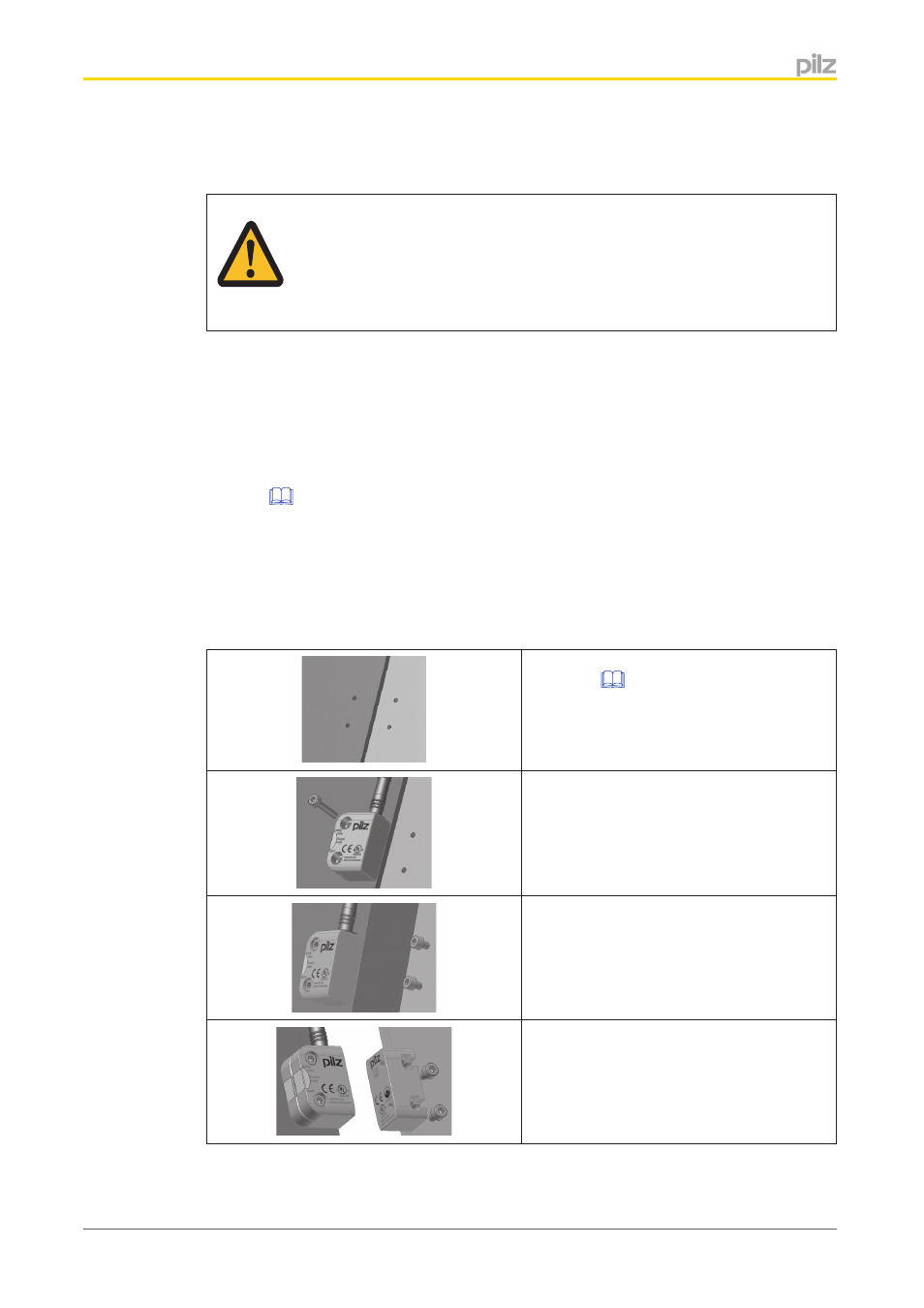

Parallel assembly

Drill holes in the mounting surface (see

) and cut threads in the

holes for M4 screws.

Use a screw to fix the safety switch in place.

1. Do not fully tighten the 2nd screw on the

safety switch.

2. Attach the screws for the actuator, leav-

ing a distance of 3 … 6 mm between the

screw head and plate.

Slide the actuator on to the mounting sur-

face. The inscribed area on the actuator

(sensing face) should face the safety switch.