5 scale selection, 6 weight and balance, 5 scale selection 1.6 weight and balance – Rice Lake TradeRoute HL Series - Installation and Service Manual (Legal-for-Trade) User Manual

Page 8

4

Trade

Route Installation Manual

1.5

Scale Selection

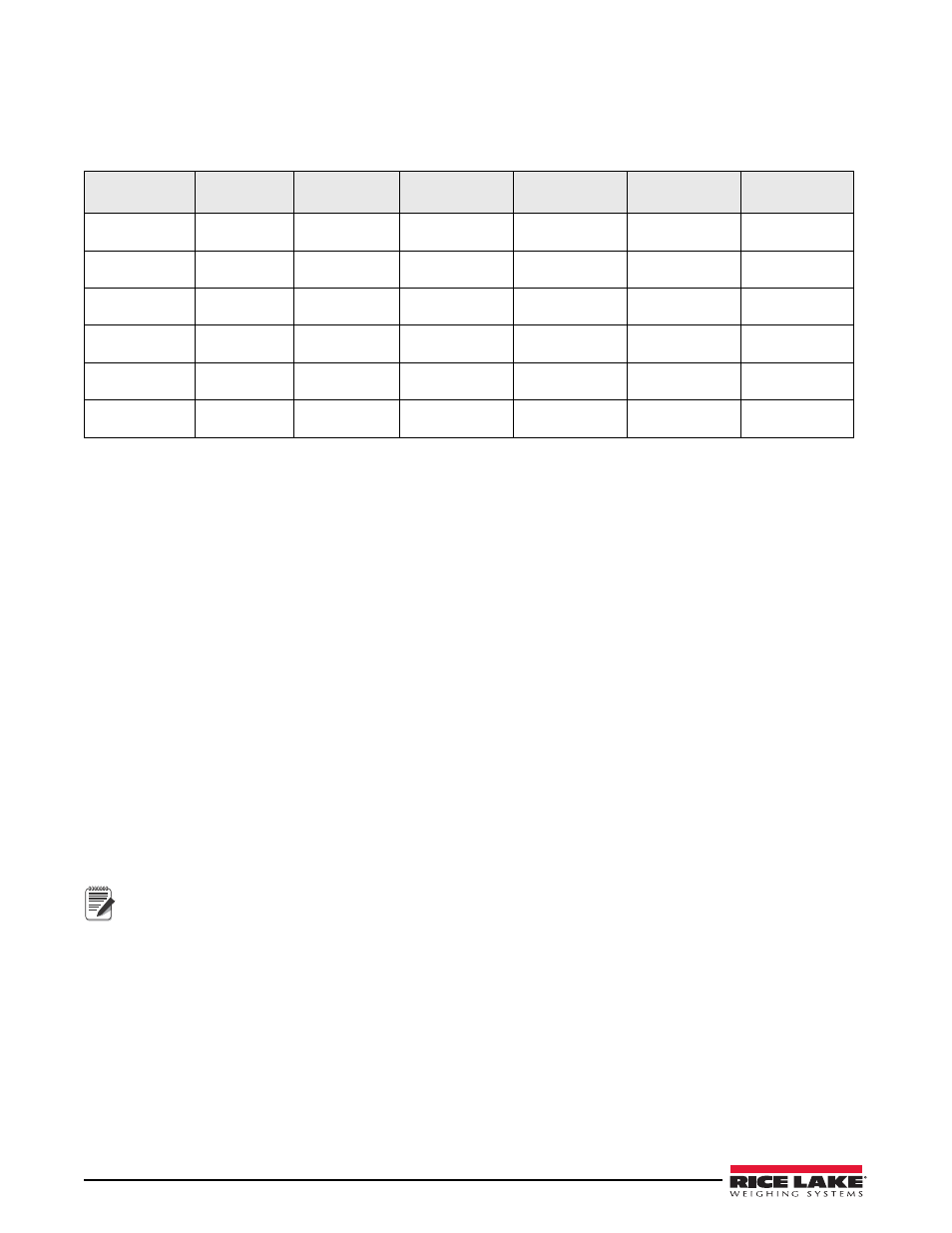

The capacity of the scale selected must be able to carry the empty weight of the container/delivery body (tare

weight) plus the maximum product that can be carried by the container (maximum net weight). Use the following

chart to select the proper scale capacity.

Table 1-1. Number of Assemblies Required by Capacity

Capacity

Required

OB5-SGL5

OB10-DBL5

OB10-SGL10

OB20-DBL10

OB15-SGL15

OB30-DBL15

15,000 lb

(7000 kg)

1

1

20,000 lb

(9,000 kg)

2

30.000 lb

(13,500 kg)

1

1

40,000 lb

(18,000 kg)

2

45,000 lb

(20,000 kg)

1

1

60,000 lb

(27,000 kg)

2

1.6

Weight and Balance

The objective of the weight and balance calculation is to determine the truck’s resulting axle weights when the

system is installed. It is important that the allowable axle weight limits of the truck and allowable road limits are

not exceeded.

A worksheet outlining the calculation is shown on the following page.

1. Measure the wheelbase of the truck. This is the distance from the front axle to the center of the rear axle

group.

2. Obtain the initial axle weights of the truck without the container (delivery body).

3. Allow a minimum clearance of 2

"

from any part of the scale (scale frame, tanks) to any fixed obstruction

on the truck (cab, exhaust stacks). This is required for proper scale operation.

4. Estimate the center of gravity of the container or delivery body. The center of gravity can usually be

estimated as the center of the container.

5. Select a starting position for the body or container on the truck frame. The container center of gravity must

be ahead of the rear axle group.

6. Assuming the starting position as previously described, determine the forward distance (FD) from the

center of the rear axle group ahead to the body’s center of gravity. This dimension can be calculated or

measured with a tape measure.

7. Determine the total weight of components being installed on the truck.

8. Determine final axle weights using the equations below the worksheet.

Note

If one of the axle weights is greater than the allowable limit for the truck or roads, shift the body forward (to

lower the rear axle weight) or backward (to lower the front axle weight), keeping in mind points 3, 5 and 6

above.

9. Extend the truck frame if required. If the weigh module hangs past the end of the truck frame, the truck

frame must be extended. The truck frame must be at least even with the end of the weigh module. It is

recommended that the truck frame extend a minimum of 1

"

past the weigh module.

10. It is preferred that the rear bumper be mounted directly to the truck frame.