5 board removal, 6 replacement parts, 7 instrumentation setup – Rice Lake IQ 700 Configurable Weight Indicator User Manual

Page 9: Ep–1.15, Caution, Eprom set 1 version 15

Installation and Wiring

5

6. Cut circuit traces between E7/E8 and E9/E10 as

indicated with a sharp instrument like a razor

blade or an X-acto

®

Figure 2-2. Circuit Trace Setup

7. Add jumper, E8 to E9 using a properly insulated

wire with a minimum size of #22 AWG.

8. Replace the protective insulator panel.

9. Change the power cord.

10. Reassemble the unit, test, and label unit for

230VAC.

2.5

Board Removal

If you must remove the IQ 700 CPU board, use the

following procedure:

1. Disconnect power to the indicator. Loosen cord

grips and remove enclosure as described in

Section 2.2.

2. Unplug all connections to the CPU board.

3. Remove the four corner screws from the

standoffs.

4. Remove the four screws from the corners of the

CPU board.

5. Remove the CPU board from the enclosure.

To replace the CPU board, reverse the procedure. Be

sure to reinstall cable ties to secure all cables inside the

indicator enclosure. Replace the enclosure and torque

screws.

2.6

Replacement Parts

Table 2-1 lists the replacement parts for the IQ 700.

2.7

Instrumentation Setup

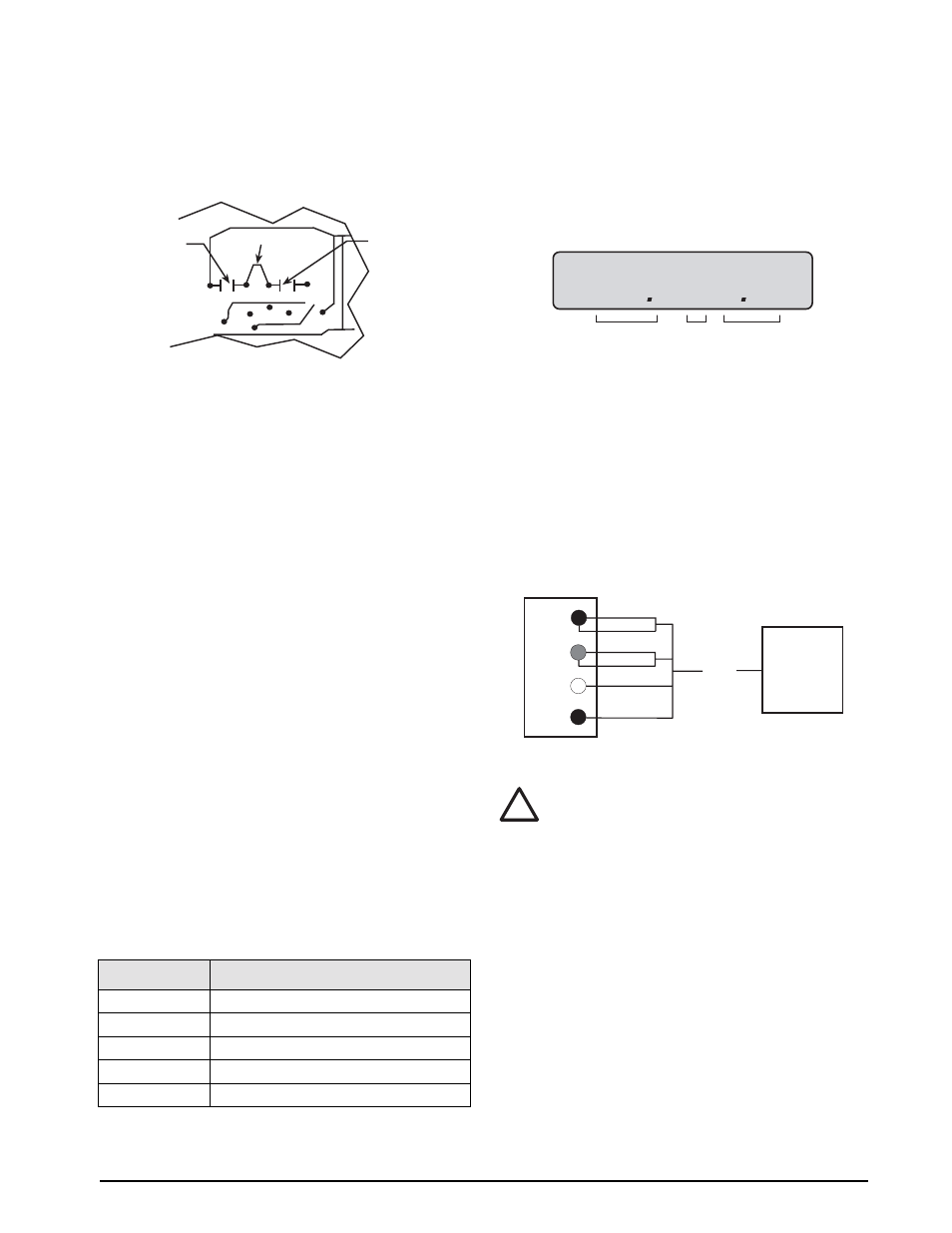

The IQ 700 operates with the EPROM program

KDA1921-1(27C512). To verify the program installed

in the indicator, turn on the indicator and observe the

displayed value at the EP prompt (see Figure 2-3). The

EP prompt displays the family, set, and version level of

the installed EPROM.

Figure 2-3. EPROM Display

To ensure that the IQ 700 is in proper operating

condition, the indicator can be tested with a load cell

simulator. The input signal should be as close as

possible to the normal system millivolt value.

Figure

2-4 shows the simulator-to-indicator wiring

connection in a six-wire configuration. See Section 2.8

on page 6 for more information.

NOTE:

Six-wire configuration requires that the +SEN

lead be shorted to +EXC and the –SEN lead be shorted

to –EXC at the simulator only.

Figure 2-4. Wiring Connection to Simulator

Exceeding rated load cell load or

shorting excitation wires may

damage power supply.

19571

AC CPU RFI assembly

19573

LED display board

19574

21-keyboard assembly

19404

Overlay

19600

LCD display board

Table 2-1. IQ 700 Replacement Parts

E7

E8 E9

E10

Jumper E8 to E9

Cut between

E7 and E8

Cut between

E9 and E10

Circuit Side of CPU Board

Converting from 115V AC to 230V AC

EP–1.15

EPROM Set 1 Version 15

LOAD CELL

SIMULATOR

TO J1

CONNECTOR

IQ700 HB

+SIG

–SIG

+EXC

–EXC

–SEN

+SEN

–EXC

+EXC

+SIG

–SIG

!

Caution