Reglazing-procedure – Oldcastle BuildingEnvelope ICR-225 User Manual

Page 30

27

March 2012

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

I C R - 2 2 5 - I N S T A L L A T I O N M A N U A L

REGLAZING PROCEDURES

NOTE: These instructions cover the replacement of glass below an intermediate horizontal or head

member. Glass size for reglazed lites is D.L.O. + 1” at captured systems.

A.1

A.2

Remove face cap from members above affected lite.

Remove lite of glass and all glazing gaskets from opening to be glazed.

A.3

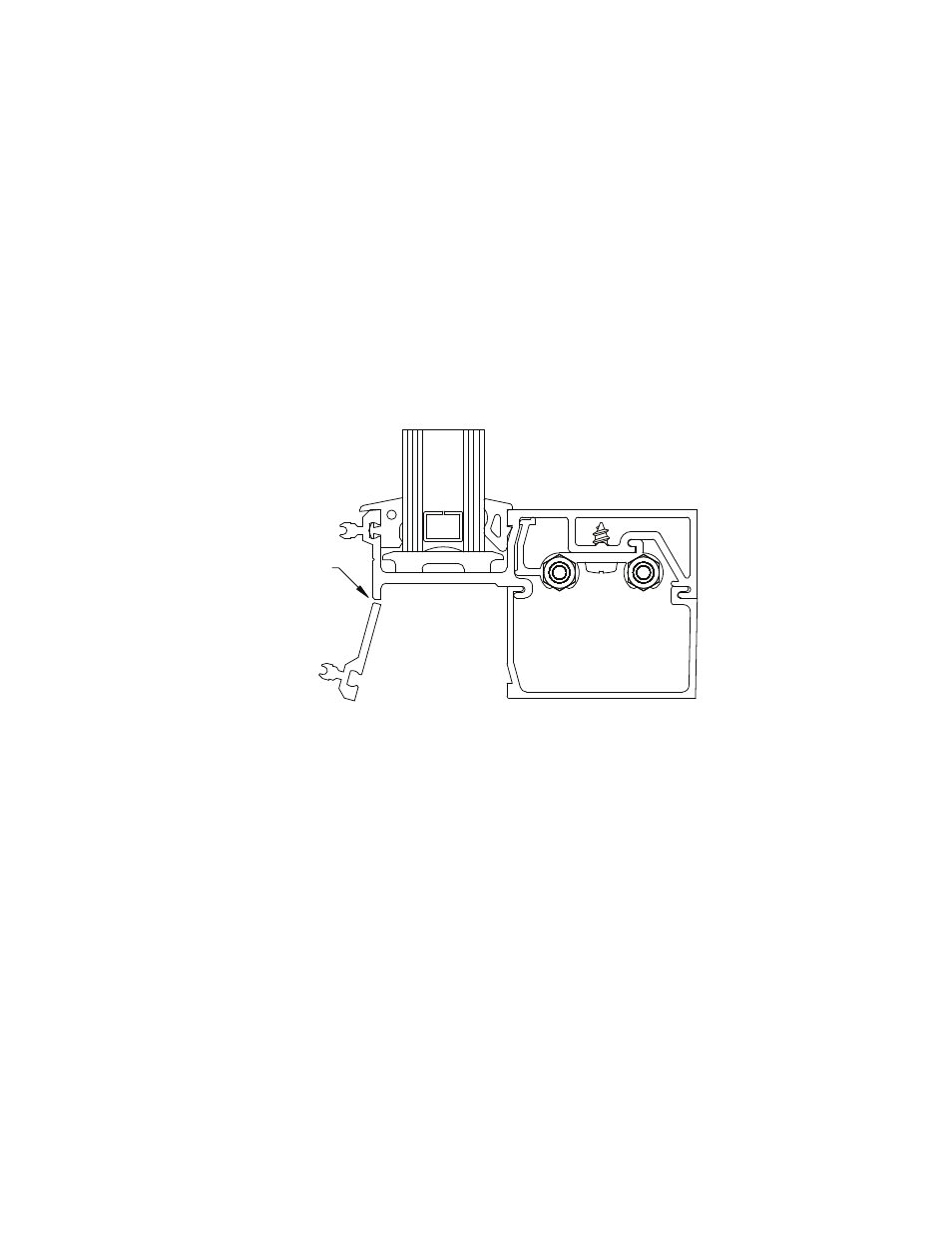

The bottom leg of the horizontal or head above the removed lite must be cut away. Carefully cut along

the V-groove along the face of the leg.

SEE FIGURE 30.

A.5

Glaze new lite, checking to make sure the setting chair and setting block are properly located. Care

must me taken during glazing so as not to disturb interior gasket. Hold glass in place temporarily with

short pieces of the edge gasket at the side of the lite.

Modification for Exterior Reglazing

(Shear Block Horizontal Shown. Head and Screw Spline Horizontal Require Same Modification)

Figure 30

Cut at V-Groove

A.6

Run a continuous bead of sealant along the face of horizontal, then screw apply the reglazing adaptor

with FS-55 #10 x 1/2” Phillips Pan Head screws at 12” O.C. (1 1/2” from ends). Seal heads of all

fasteners. Pre-drill or notch face of reglaze leg at weep holes.

SEE FIGURE 31, page 28

A.7

Install wedge gasket around exterior of lite and seal all corners. Replace horizontal face caps to

complete the reglazing procedure.