Frame-assembly-typea, Frame assembly type “a – Oldcastle BuildingEnvelope ICR-225 User Manual

Page 11

8

March 2012

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

I C R - 2 2 5 - I N S T A L L A T I O N M A N U A L

2.3

2.2

2.1

Prior to applying sealant to any frame member, the aluminum must be cleaned. Consult sealant manufacturer

for cleaning recommendations. Steps 2.1 through 2.4 refer to screw spline assembly of system.

Refer to Step

2.5 for optional installation of shear block horizontals.

Attach ICR-112-01 mull caps using (2) FS-320 #10 U-Drive fasteners. Install and seal as shown in

FIGURE 8, page 9 . The attachment and sealing of the mull caps is one of the most critical phases of

the installation of the Type “A” assembly. Special care and attention should be given to this process.

Install ICW-12 isolator clips on all vertical and horizontal framing members at 12” O.C. Stagger the

clips by approximately 2” at the ends and 6” at intermediate clips.

SEE FIGURE 9, page 10. Once

clips are installed, snap face caps into position. The vertical caps should be installed first, then

horizontal, head and sill caps.

Seal ends of horizontal framing members before assembly.

SEE FIGURE 9, page 10.

If optional head reinforcing sleeves are used (6” system only), refer to Section B, page 29, for

instructions before proceeding.

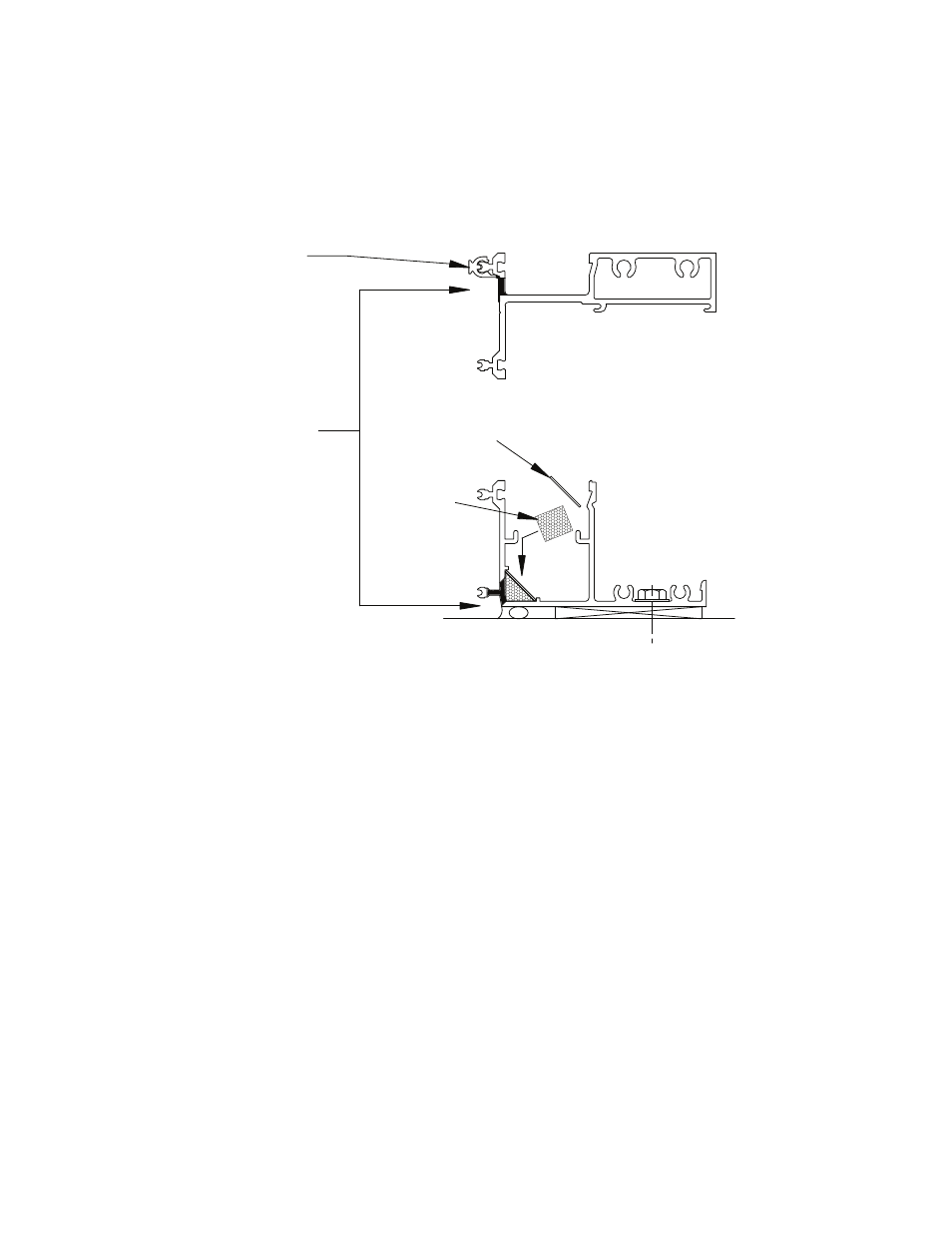

SPW- 295

Baffle

Retainer

HP- 1004

Baffle

Weep Holes

Figure 7

Horizontal

Sill

5/16” Dia. Weep Hole

ICR- 312 Baffle

clip @ Weeps

FRAME ASSEMBLY TYPE “A”