End-cap-attachment-typeb – Oldcastle BuildingEnvelope ICR-225 User Manual

Page 20

17

March 2012

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

I C R - 2 2 5 - I N S T A L L A T I O N M A N U A L

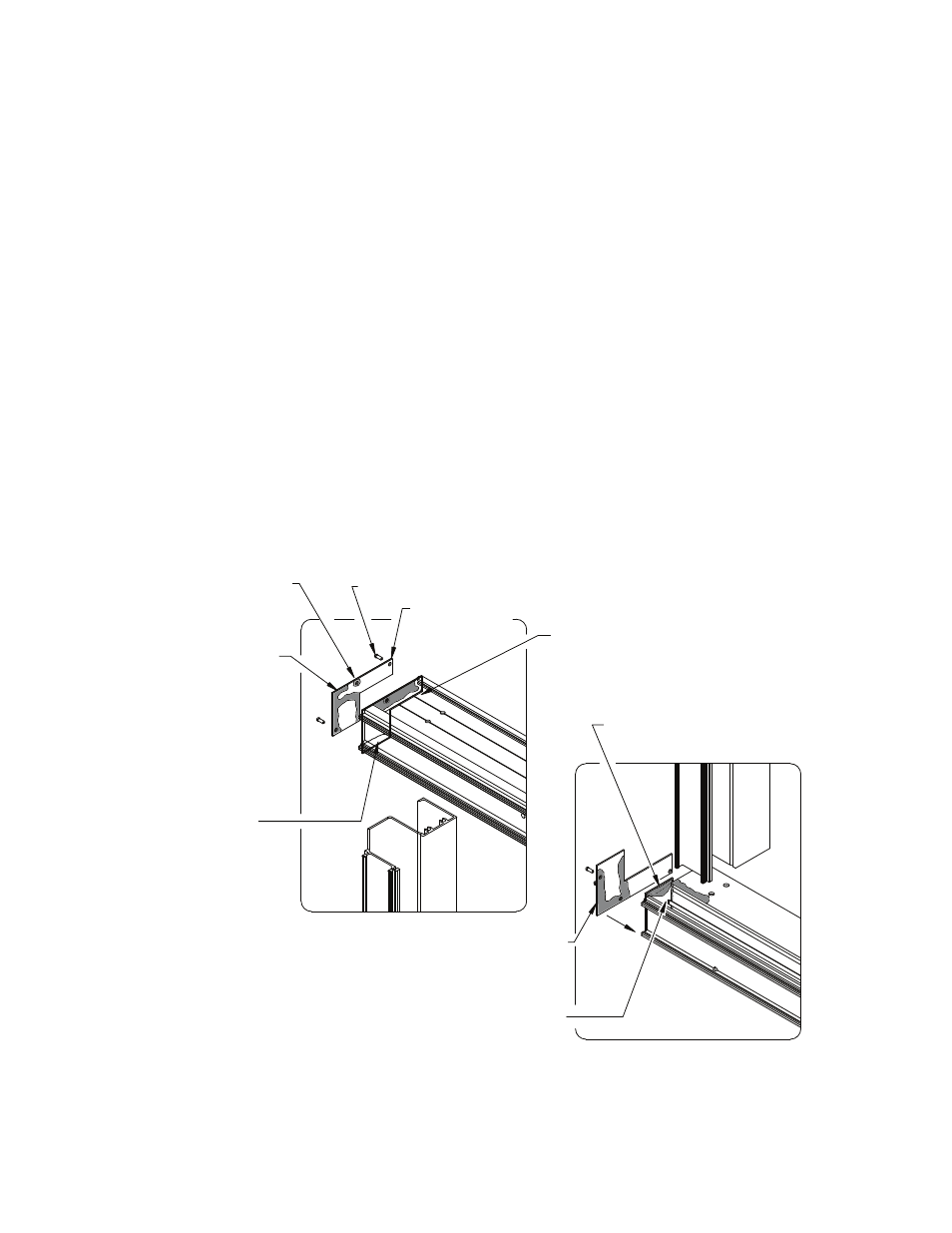

If frame has horizontals, attach Shear Blocks to jambs and vertical mullions with (2) FS-9 #14 x 1 ½”

Hex Head screws.

5.1

5.3

5.2

FRAME ASSEMBLY TYPE “B”

If optional Head & Sill reinforcing sleeves are used (6” system only), refer to Section B, page 29

for instructions before proceeding.

Attach jambs and vertical mullions to the head and sill using (2) FS-8 #14 x 1” Hex Head screws (4 ½”

system) or (4) FS-8 #14 x 1” Hex Head screws (6” system). If head is to be used for incidental water,

screws must be cap sealed.

If frame is to accommodate incidental water at the head, slide strap anchors into head member

prior to installing end caps (STEP 5.3) and setting the frame in the opening.

Attach aluminum end caps to each end of head and sill members with (2) FS-320 U-drive set in sealant

and cap sealed.

See FIGURE 17

.

ICR-109-01

FS-320

Seal over extra hole

FIGURE 17

End Cap Attachment

Fully seal pocket

ICR-109-01 (ICR-130-01)

(ICR-130-01

)

Apply sealant to End

Cap before installing

Apply sealant to

bottom of End Cap

prior to attaching Jamb

Apply sealant to top of

End Cap prior to

attaching Jamb

Seal upper section of

End Dam for incidental

water only

Prior to applying sealant to any frame member, the aluminum must be cleaned. Consult sealant

manufacturer for cleaning recommendations.