Frame-assembly-typea, Frame assembly type “a – Oldcastle BuildingEnvelope ICR-225 User Manual

Page 12

9

March 2012

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

I C R - 2 2 5 - I N S T A L L A T I O N M A N U A L

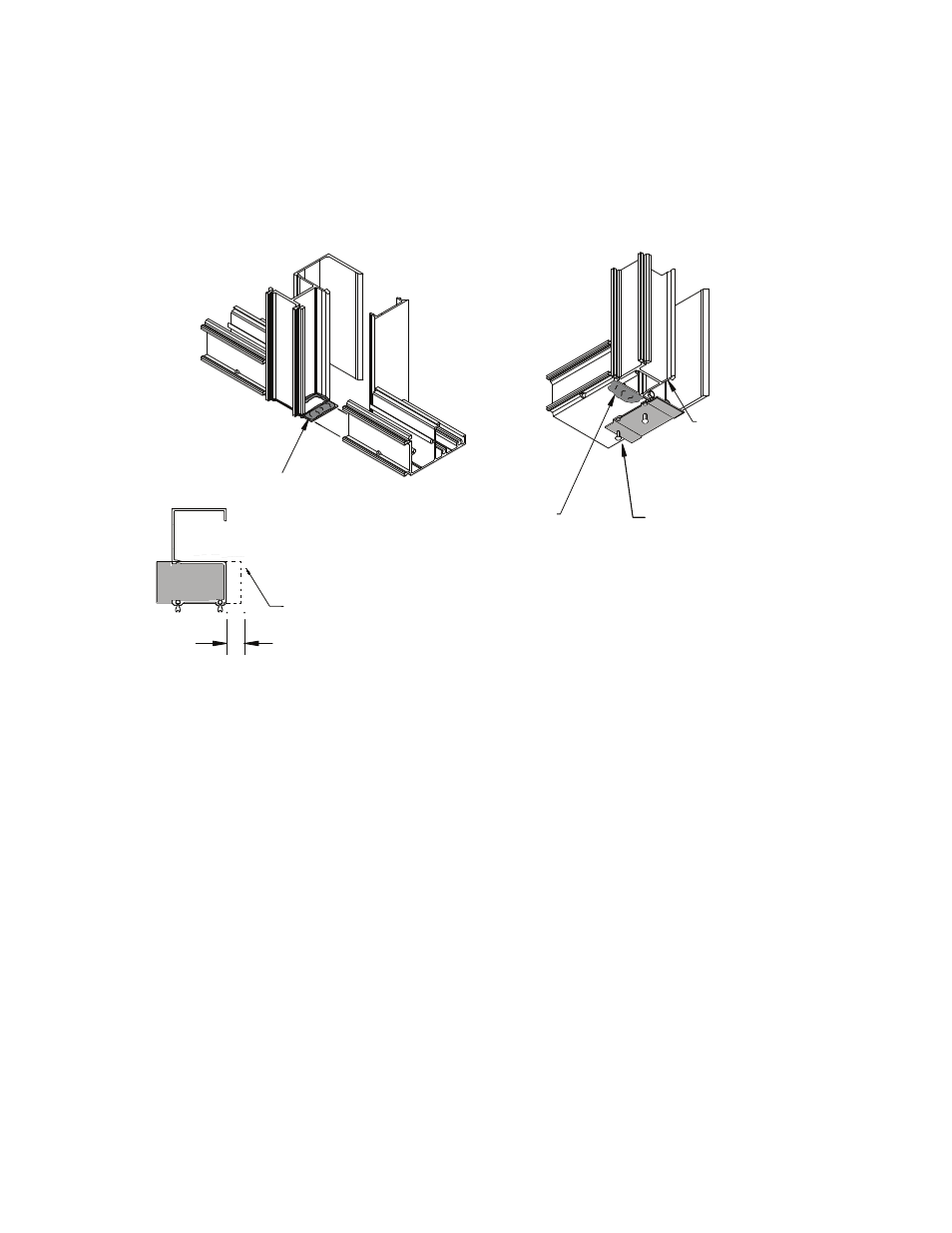

FRAME ASSEMBLY TYPE “A”

Apply bead of sealant

at Head and Sill

Tool sealant in glazing after installing

Mull Cap to insure proper seal

Apply sealant to

ends of Mullion

prior to installing

Mull Cap

Attach with (2)

FS-320 Drive Pins

Mull Cap Attachment

Figure 8

Modify ICR-112-01

Mull Cap

5/8"

Modify Mull Cap

as shown at Jamb

Apply generous bead of sealant

to Mull Cap at Head and Sill just

prior to assembly of units

2.4

Attach head, sill and intermediate horizontals to verticals with (2) FS-8 #14 x 1” Hex Head screws. DO

NOT OVER TORQUE SCREWS.

SEE FIGURE 9, page 10.

Optional shear block horizontals may be used with Type “A” installations. Begin by installing ICR-

180-01 (ICR-181-01) shear blocks to verticals using (2) FS-9 #14 x 1-1/2” Hex Head screws. Prior to

attaching horizontals to shear blocks apply sealant to face and top of shear block and along front edge

of vertical in line with face of horizontal. Roll the horizontal over the shear block and attach with (1)

FS-55 #10 x ½” Phillips Round Head screw.

SEE FIGURE 21, page 20.

2.5