Frame-iinstallation-typea – Oldcastle BuildingEnvelope ICR-225 User Manual

Page 14

11

March 2012

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

I C R - 2 2 5 - I N S T A L L A T I O N M A N U A L

FRAME INSTALLATION TYPE “A”

3.1

Install frame sections starting with a frame unit comprised of a jamb and vertical mullion with head/sill

and horizontals. Each additional frame unit will be made from mullion filler and a mullion until you

reach the opposite end of the opening. The final frame member will be made from the mullion filler and

a jamb. (This description assumes a ribbon installation with a jamb at each end. Your installation may

vary.)

A.

B.

C.

D.

Each frame unit will be assembled and sealed as shown in

FIGURE 8, page 9 and FIGURE 9,

page 10 with mullion caps installed as shown in FIGURE 8, page 9 . A second bead of sealant is

applied to the face cap that is protruding into the opening just prior to assembly of the frame units.

SEE FIGURE 8, page 9. NOTE: Sealant must be tooled at head and sill to insure proper

seal.

When installing each unit, first slide head member over the head anchor, which has been

previously installed, and rotate unit into position. Each adjacent unit will be rotated into position,

between the mull caps at the head and sill, and snapped into position. (A furniture clamp may

be use to simplify the snapping of units together.)

NOTE: When optional head reinforcing

sleeves are used (6” system only), slide head member into position over head anchor so

that reinforcing sleeve is centered on head anchor.

Make sure each unit is plumb, square and level, anchoring each unit as it is installed

.

Once all units are installed inspect caulk joints to insure uniformity.

NOTE: For optimal performance of Head Anchor, Die Lines must be visible on the Anchor at the top of

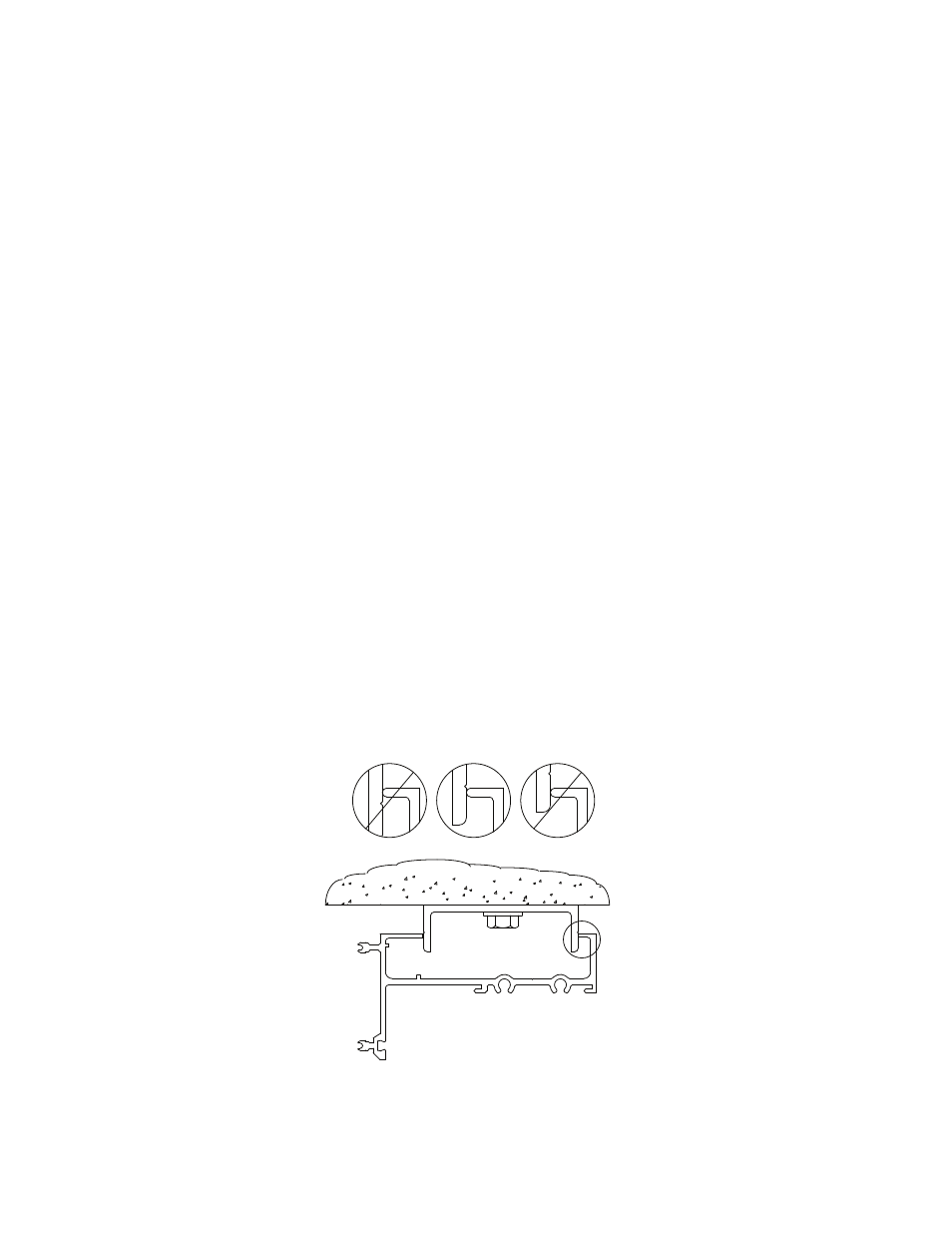

the Frame. SEE FIGURE 10 below.

Figure 10

Head Anchor Position

CORRECT