Carrier 48HJD005-007 User Manual

Page 19

19

Step 9 — Adjust Evaporator-Fan Speed —

Ad-

just evaporator-fan speed to meet jobsite conditions.

Tables 5A and 5B show fan rpm at motor pulley settings.

Tables 6 and 7 show maximum amp draw of belt-drive motor.

Table 8 shows motor nominal horsepower for evaporator-fan

motors. Refer to Tables 8-25 for performance data. See Tables

26 and 27 for accessory and option static pressure drops.

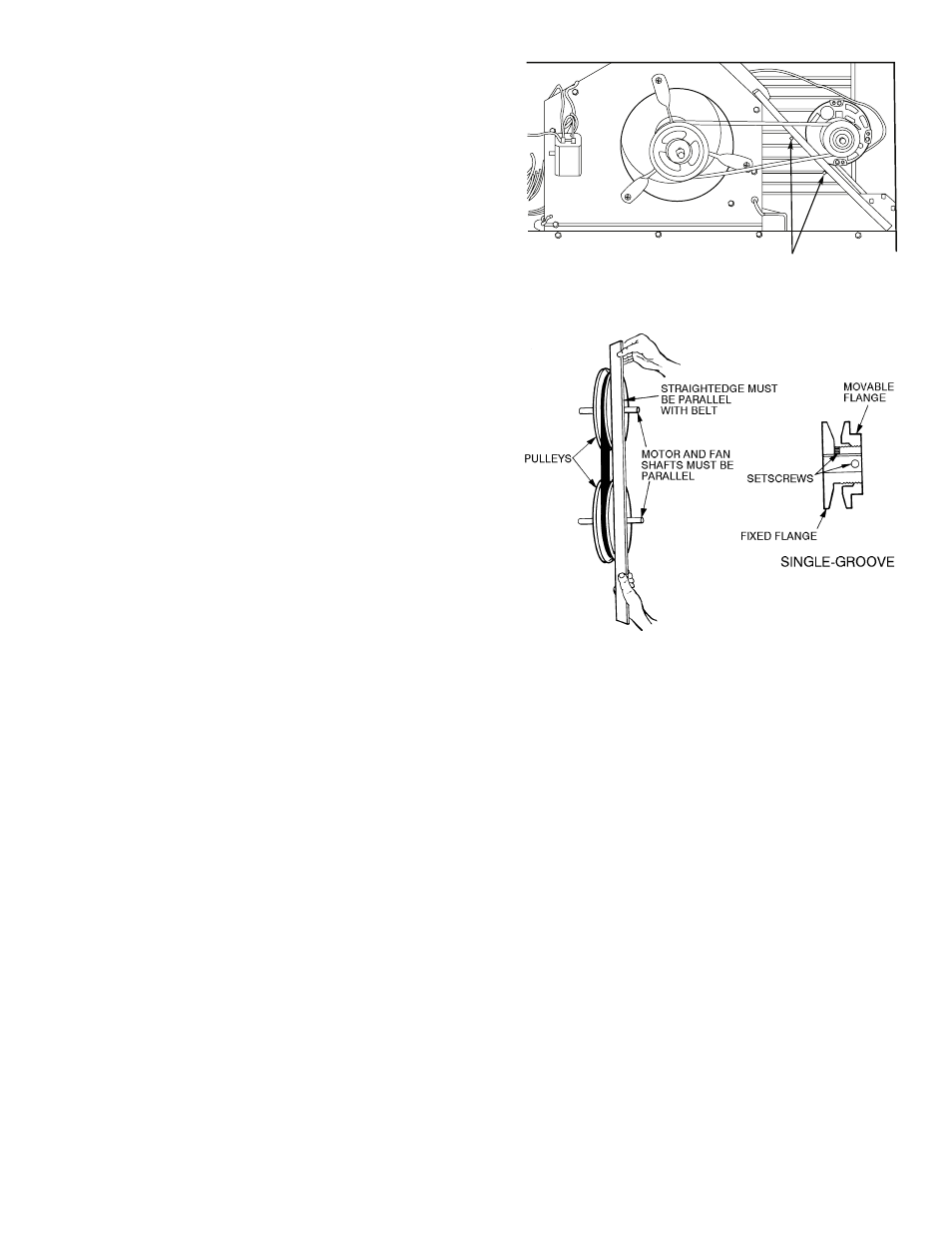

BELT-DRIVE MOTORS — Fan motor pulleys are factory set

for speed shown in Table 1. Check pulley alignment and belt

tension prior to start-up.

NOTE: Before adjusting fan speed, make sure the new fan

speed will provide an air temperature rise range as shown in

Table 1.

To change fan speed:

1. Shut off unit power supply, tag disconnect.

2. Loosen belt by loosening fan motor mounting nuts. See

Fig. 37.

3. Loosen movable pulley flange setscrew (see Fig. 38).

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed. In-

creasing fan speed increases load on motor. Do not ex-

ceed maximum speed specified in Table 1.

5. Set movable flange at nearest keyway of pulley hub and

tighten setscrew. (See Table 1 for speed change for each

full turn of pulley flange.)

To align fan and motor pulleys, loosen fan pulley setscrews

and slide fan pulley along fan shaft. Make angular alignment

by loosening motor from mounting.

To adjust belt tension:

1. Loosen fan motor mounting nuts.

2. Slide motor mounting plate away from fan scroll for

proper belt tension (1/2-in. deflection with 8 to 10 lbs of

force) and tighten mounting nuts.

3. Adjust lock bolt and nut on mounting plate to secure mo-

tor in fixed position.

MOTOR MOUNTING

PLATE NUTS

Fig. 37 — Belt-Drive Motor Mounting

Fig. 38 — Evaporator-Fan Pulley Adjustment