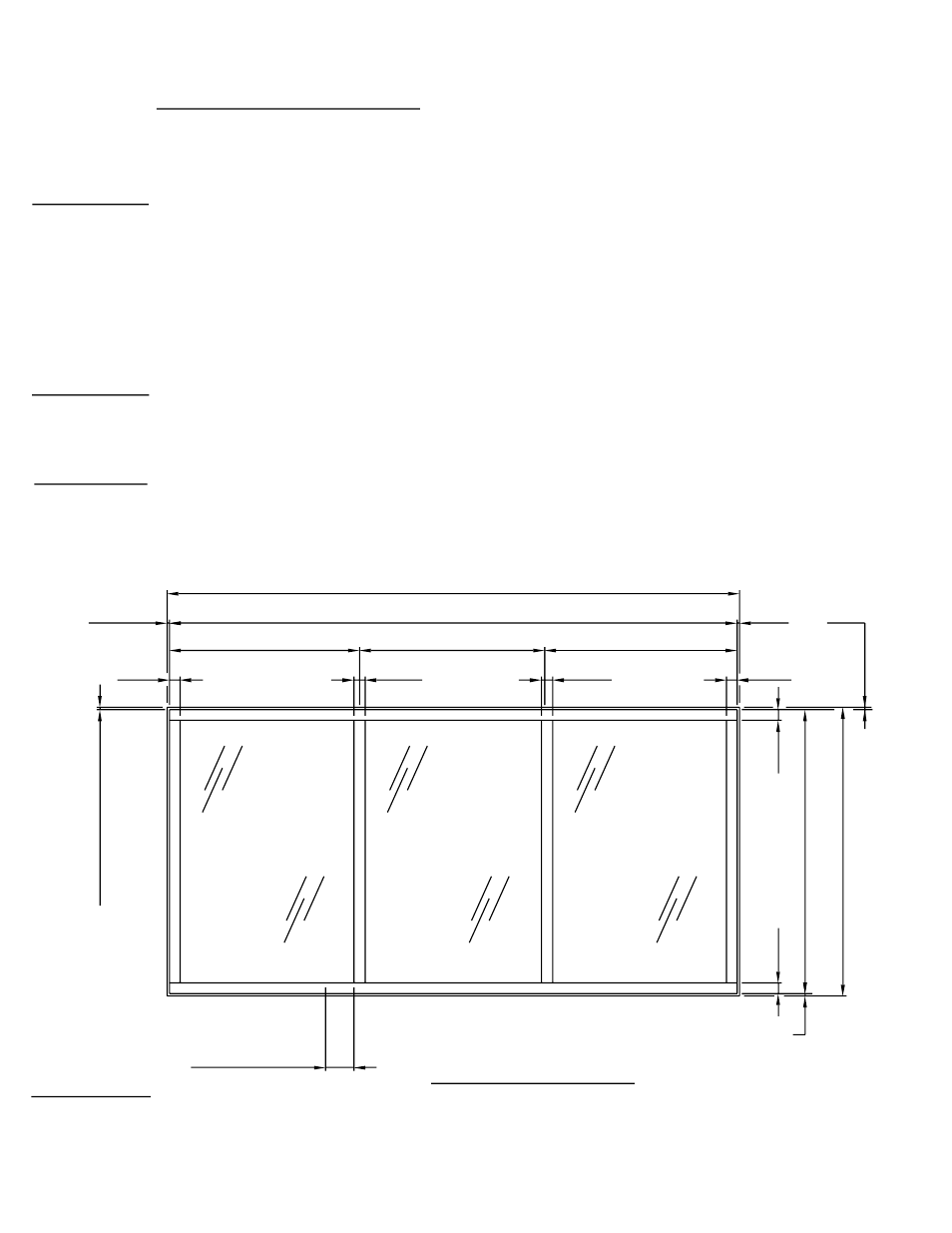

Head & sill fabrication, Drill jig gu, Step #4 – EFCO 955 Series User Manual

Page 14: Elevation #1, Step #3, Step #2, Head and sill fabrication and preparation step #1

required. See pages #6 thru #11 for the drill jigs and drill jig guides required

MULL. CENTER

1/2" BTM. CAULK JOINT

Drill the sill member for two 1/4" weep holes per daylight opening, at 6" from each mullion.

Establish and mark the mullion center lines and jamb locations on the head

Position the drill guides over the mullion and jamb locations and drill as

Cut the head and sill members to the rough opening measurement minus

top of the sill and at the snap location of the removable stop at the head.

and sill running through. The jambs and vertical mullions will meet at the

3/4" TOP CAULK JOINT

See Elevation #1 above and Detail #5 & #6 on page #13.

STEP #4

TYPICAL

FROM MULL

WEEP 6"

ELEVATION #1

depending upon the condition. See Elevation #1 below.

and sill. Mullion widths are 2 3/8" as shown below.

(-) the vertical caulk joints. This dimension could be 1/4" through 3/4"

STEP #3

2 1/4"

JOINT

CAULK

MULL. CENTER

STEP #2

FRAME WIDTH

MULL. CENTER

ROUGH OPENING WIDTH

2 3/8"

2 3/8"

2 1/4"

2 1/4"

FRAME HEIGHT

ROUGH OPENING HEIGHT

JOINT

CAULK

2 1/4"

SECTION IV - FABRICATION

The series 955 Tech Set system is designed to be fabricated with the head

HEAD AND SILL FABRICATION AND PREPARATION

STEP #1

PAGE #12

for assembling this system.

JDA 9/2000