EFCO 8800 Series Assembly Instructions Vol.3 User Manual

Page 28

EFCO 2009

Page 28

Series 8700 / 8800 Unitized Curtain Wall Installation Instructions - Volume 3

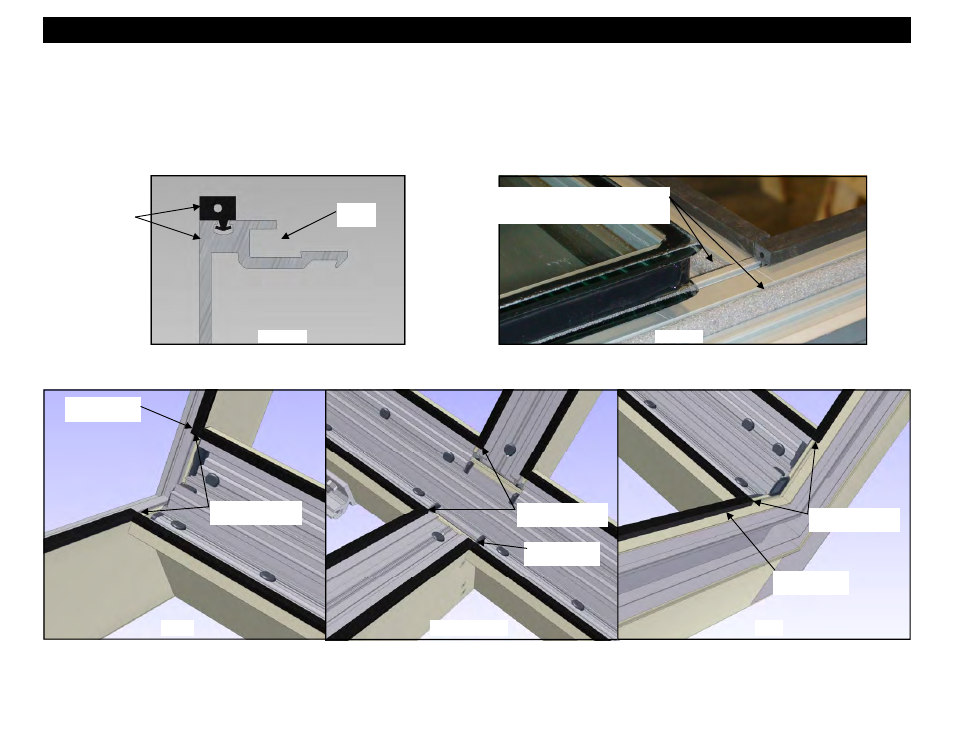

Section 10 - Inside 90° Corner Unit Glazing Preparation : SSG and Captured

Figure 65

5. Apply the WC18 spacer gasket to the mullions as shown below and on the previous page. The gasket will run through as shown below. Butt the gaskets

together at the corners (see Figures 68, 69 and 70). “Crowd” in extra gasket, (approximately 4% to 5% extra) where it runs between the gaskets to ensure a

snug butt joint at the corners. It is important that there are no gaps in the gaskets where they meet in the corners. Note that the gasket is not symmetrical,

and must be installed so that it is flush with the side of the mullions (see Figure 66).

6. A 3/8” backer rod should be applied into the isolator reglet to prevent sealant from getting into the reglet. Remove the backer rod immediately after the

sealant is applied, and before the sealant begins to cure and skin over (See Figure 76).

Apply gaskets

flush with the side

of the mullions.

Isolator

Reglet

Insert a 3/8” backer rod into isolator reglets to

keep free of sealant. Remove the backer rod

immediately, before sealant begins to skin over.

Figure 72

Butt gaskets at

D.L.O. corners.

SILL

INTERMEDIATE

HEAD

Horizontal gaskets

run through.

Butt gaskets at

D.L.O. corners.

Figure 73

Figure 74

Figure 75

Figure 76

Butt gaskets at

D.L.O. corners.

Horizontal gaskets

run through.

Refer to Volume 2, page 7 for spacer

gasket configuration at the jamb mullions.

Horizontal gaskets

run through.