EFCO 8800 Series Assembly Instructions Vol.3 User Manual

Page 21

EFCO 2009

Page 21

Series 8700 / 8800 Unitized Curtain Wall Installation Instructions - Volume 3

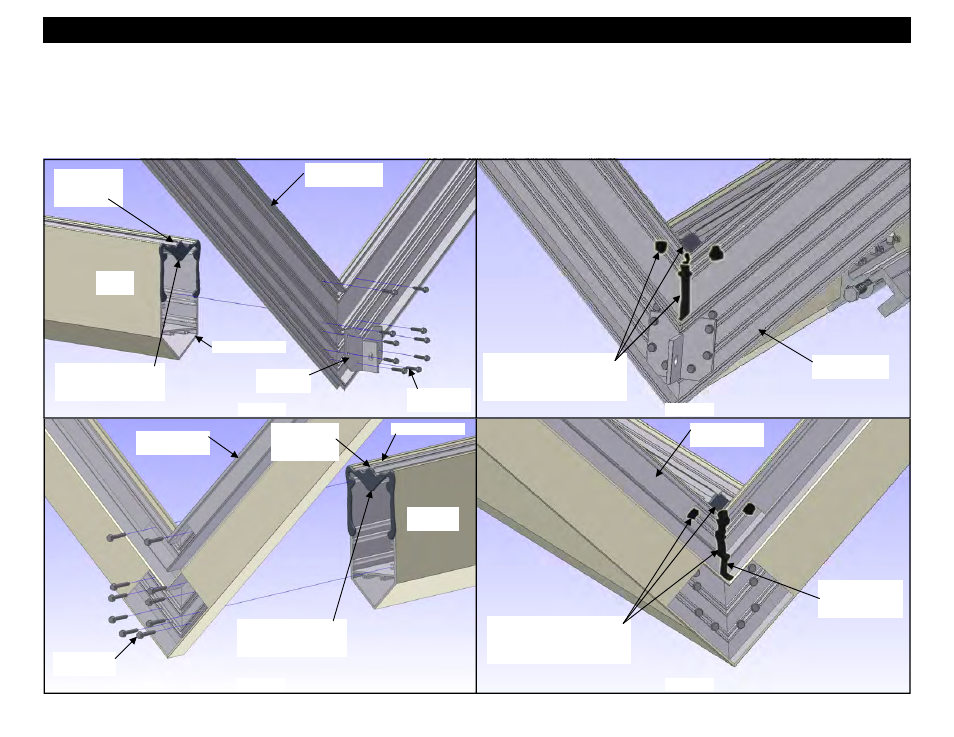

Section 8 - B. Inside 90° Corner Unit Frame Assembly

27. Once the stack head and sill assemblies have been attached, remove all excess sealant from areas that will be exposed to the interior.

28. Remove excess sealant from gasket reglets and areas where the isolator clips and adapters will later be inserted.

29. Using an approved solvent or cleaner, clean the sealant contact surfaces of the mitered areas of the stack head and sill assemblies.

30. Apply a generous bead of silicone sealant along the miter and at the fastener heads of the stack head and sill assemblies as shown in Figures 56 and 58.

31. Tool the sealant into all voids and reglets to make water tight. Avoid excessive sealant build-up in the stack sill where the units stack together.

Figure 55

17H1 Stack

Head Assembly

Figure 56

FM20 Unit

Lifting Lug

17H0 Stack Sill

Assembly

SFQ5 Frame

Screws

Corner Mullion

SFQ5 Frame

Screws

Corner Mullion

Butt seal the end of

the corner mullion and

the top of the angle.

17H1 Stack

Head Assembly

Apply a generous bead of

sealant and tool into voids

and reglets. Cap seal fastener

heads where indicated.

17H0 Stack Sill

Assembly

Avoid excessive

sealant build-up

in this area.

Figure 58

Figure 57

Top of

Mullion

Bottom

of Mullion

Butt seal the end of

the corner mullion and

the top of the angle.

Apply a generous bead of

sealant and tool into voids

and reglets. Cap seal fastener

heads where indicated.

Cap seal

fastener head

at angle.

Cap seal

fastener head

at angle.