EFCO 8800 Series Assembly Instructions Vol.3 User Manual

Page 17

EFCO 2009

Page 17

Series 8700 / 8800 Unitized Curtain Wall Installation Instructions - Volume 3

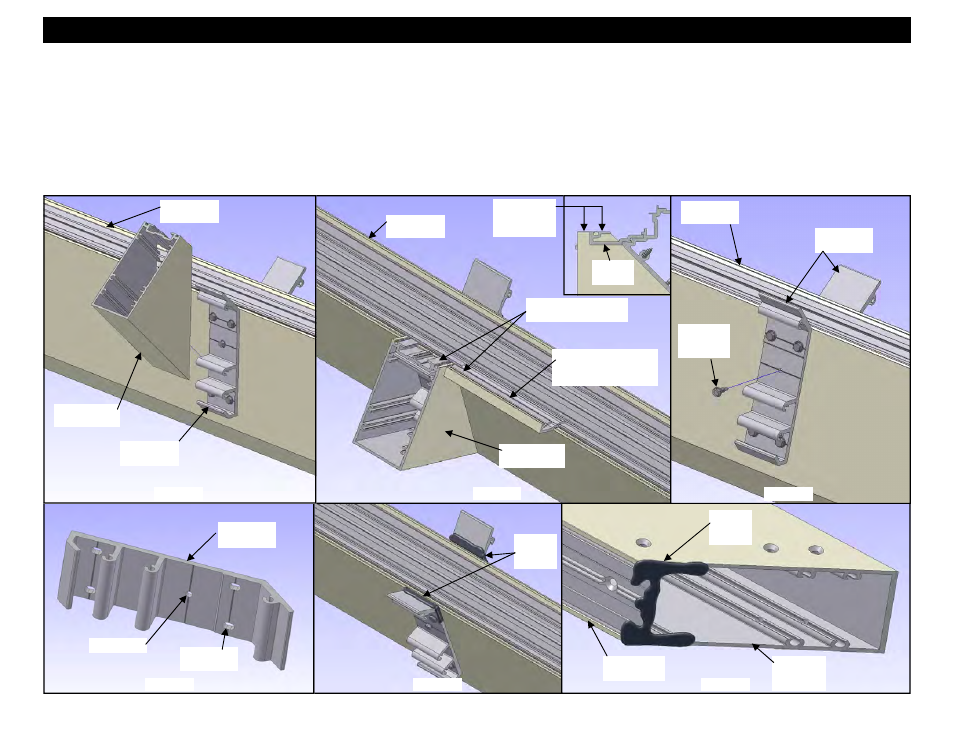

9. Use a short piece of 17E9 adapter to align the horizontal and vertical (see Figure 39). Once the shear blocks have been attached with SM00 fasteners,

adjust the shear blocks so that the face of the horizontal aligns with the face of the 17E9 adapter. Using a mitered scrap piece of horizontal as shown in

Figure 38 will aid with alignment. The shear blocks have (4) adjustment slots and (1) fixing hole for adjustment and locking them into position (see Figure 41).

10. Lock the shear block in place with (1) STK3 alignment screw (#12-14 X 3/4” HW-SMS 410 TEK 3) at each intermediate horizontal location (see Figure 40).

11. Using an approved solvent or cleaner, clean the sealant contact surfaces of the mullions and shear blocks of all oils and other contaminants.

12. Apply a generous amount of silicone sealant around the front part of the shear block as shown in Figure 42. Apply a generous bead of silicone sealant

around the front part of the intermediate horizontals as shown in Figure 43. Apply sealant to the mitered end only.

KV12 Shear

Block

Unit Corner

Mullion

Figure 38

Align face of mullion

and adapter.

Scrap Piece

of Horizontal

Intermediate

Horizontal

Figure 39

Figure 40

Figure 41

Figure 43

Figure 42

Scrap Piece

of Horizontal

KV12 Shear

Blocks

KV12 Shear

Block

Adjustment

Slots

STK3

Alignment

Screw

Unit Corner

Mullion

Fixing Hole

Apply

silicone

sealant.

Apply

silicone

sealant.

Mitered

end of

horizontal.

Section 8 - Inside 90° Corner Unit Frame Assembly : A. Mullion Subassembly

Unit Corner

Mullion

Scrap piece of 17E9

adapter used to align

shear block.

Align face of

mullion and

adapter.

17E9

Adapter