EFCO 8800 Series Assembly Instructions Vol.3 User Manual

Page 10

EFCO 2009

Page 10

Series 8700 / 8800 Unitized Curtain Wall Installation Instructions - Volume 3

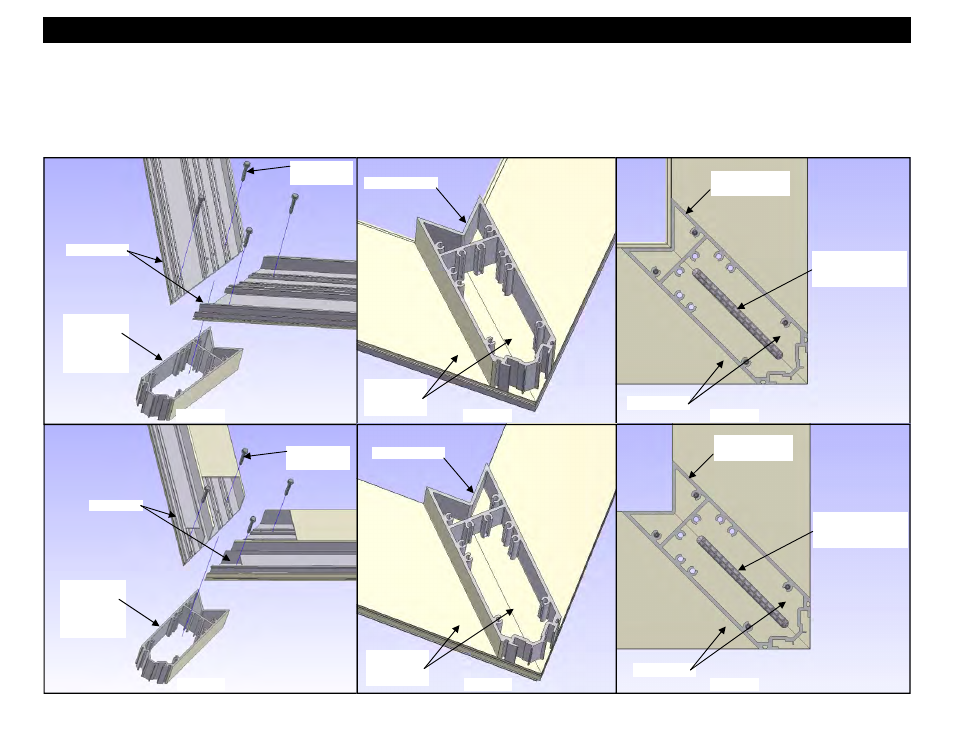

Section 7 - B. Outside 90° Corner Unit Frame Assembly

16. Assemble the mitered 17H1 stack heads using (4) SFQ5 fasteners and a 2” long piece of the 17J5 corner mullion as a welding fixture. Ensure the assembly

is completely square. Take measures to make certain the surrounding exposed finished surfaces are protected from weld spatter.

17. Apply a continuous fillet weld at the miter of the stack heads as shown in Figure 19, and remove the mullion weld fixture after the weld has cooled and set.

18. Assemble the mitered 17H0 stack sills using (4) SFQ5 fasteners and a 2” long piece of the 17J5 corner mullion as a welding fixture.

19. Apply a continuous square groove at the miter of the stack sills as shown in Figure 22, and remove the mullion weld fixture after the weld has cooled and set.

Figure 17

Figure 18

Figure 19

Figure 20

Figure 21

Figure 22

Stack Heads

2” long piece

of corner

mullion used

as welding

fixture.

SFQ5 Frame

Screws

Stack Heads

assembled

for welding.

Corner Mullion

Corner Mullion

Welding Fixture

Apply a continuous

square groove weld

as shown.

2” long piece

of corner

mullion used

as welding

fixture.

Stack Sills

SFQ5 Frame

Screws

Stack Sills

assembled

for welding.

Corner Mullion

Corner Mullion

Welding Fixture

Stack Heads

Stack Sills

Apply a continuous

square groove weld

as shown.