EFCO 8800 Series Assembly Instructions Vol.2 User Manual

Page 28

EFCO 2009

Page 28

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

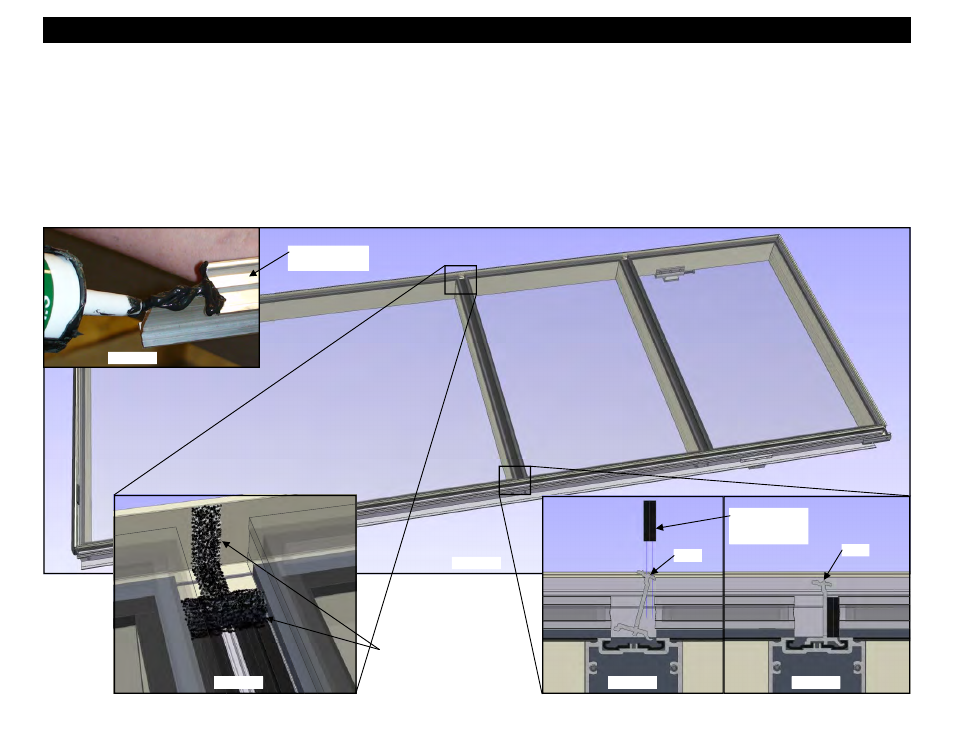

16. Using an approved solvent or cleaner, clean the surfaces of the mullions at the intersection of the intermediate horizontal and vertical.

17. Apply a heavy bead of sealant at the intersection of the intermediate horizontal and vertical (See Figure 83). The sealant should run between the structural

seals of the adjacent lites and the areas that will contact the 17B9 glazing adapter.

18. Clean the ends of 17B9 captured glazing adapter .

19. Apply beads of sealant to each end of 17B9 as shown in Figure 82.

20. Roll the 17B9 captured glazing adapter into the isolator at the horizontal as shown in Figures 84 and 85. This must be done immediately after the steps

above, before the sealant begins to cure.

21. Using a putty knife, thoroughly tool the sealant, blending it into the adjacent surfaces.

22. Insert HS31 setting blocks, (2) per location, between the glazing adapter and the glass at quarter points, or as directed per the final approved shop drawings.

Light prying pressure may need to be applied to the glazing adapter to insert the setting blocks into place (See figures 84 and 85).

Figure 85

Figure 81

Apply a heavy bead of

sealant at the intersection

of the intermediate

horizontal and vertical.

Section 6 - Captured Unit Glazing: C. Adapter and Cover Installation

Figure 84

Figure 82

Figure 83

17B9 Captured

Glazing Adapter

HS31 Setting

Blocks (2) per

location.

17B9

17B9