EFCO 8800 Series Assembly Instructions Vol.2 User Manual

Page 21

EFCO 2009

Page 21

Series 8700 / 8800 Unitized Curtain Wall Assembly Instructions - Volume 2

Section 6 - Captured Unit Glazing : B. Setting and Caulking Glazing

Apply structural silicone

sealant into the void and

tool the joint to fill the

void completely.

Insert a 3/8” backer rod

into isolator reglet to keep

free of sealant. Remove the

backer rod immediately

before sealant begins to

skin over.

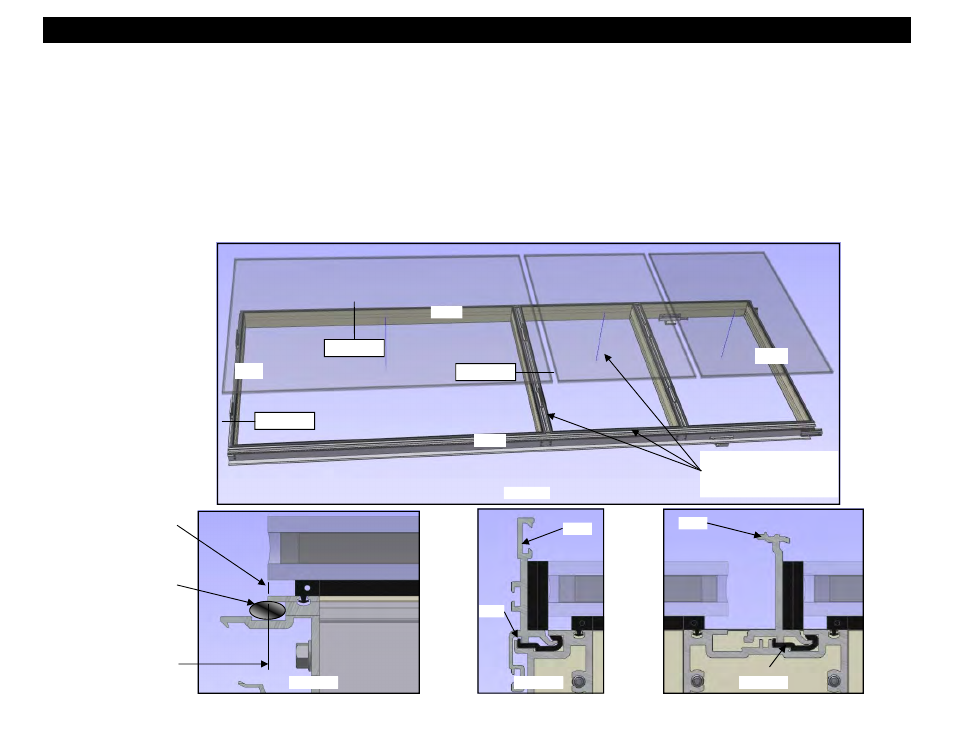

3. Set the glazing on the silicone spacer gaskets positioned as shown below. The edge of the glazing is flush with the edge of the vertical mullion. Refer to

Figure 54 below. Ensure the glazing is pressed firmly onto the setting blocks of the temporary retainers as shown in Figures 55 and 56.

4. Align the glazing as shown and noted. Ensure the glazing is positioned with the exterior side out, and the bottom of the glazing to the setting blocks. Care

should be exercised to avoid shifting or rolling the spacer gaskets when adjusting the position of the glass.

5. After the glass is aligned and in the final position, remove the setting blocks and temporary glazing locators.

6. Apply structural silicone sealant into the void between the glass and mullion per the sealant manufacturer’s application instructions. A 3/8” backer rod should

be applied into the isolator reglet to prevent sealant from getting into the reglet (see Figure 54). See additional notes, and Figures 57, 58, and 59 on page 22

for sealant application and tooling instructions.

7. Immediately tool the sealant joint after application to insure the joint is completely filled with sealant on all four sides of each piece of glazing. Make sure no

air bubbles or voids are present in the sealant joint.

8. Remove the backer rod, before the sealant begins to cure and skin over.

Glass is flush with

edge of mullion.

L142

Figure 54

Figure 55

Figure 56

Figure 53

Set glazing onto the silicone

spacer gaskets and against

the setting blocks at the

temporary glazing locators.

L142

Note:

Only silicone sealants

which have been

developed and tested

specifically for structural

glazing applications

should be used for

glazing purposes.

SILL

HEAD

JAMB

JAMB

Figure 55

Figure 54

Figure 56

KV03

KV04