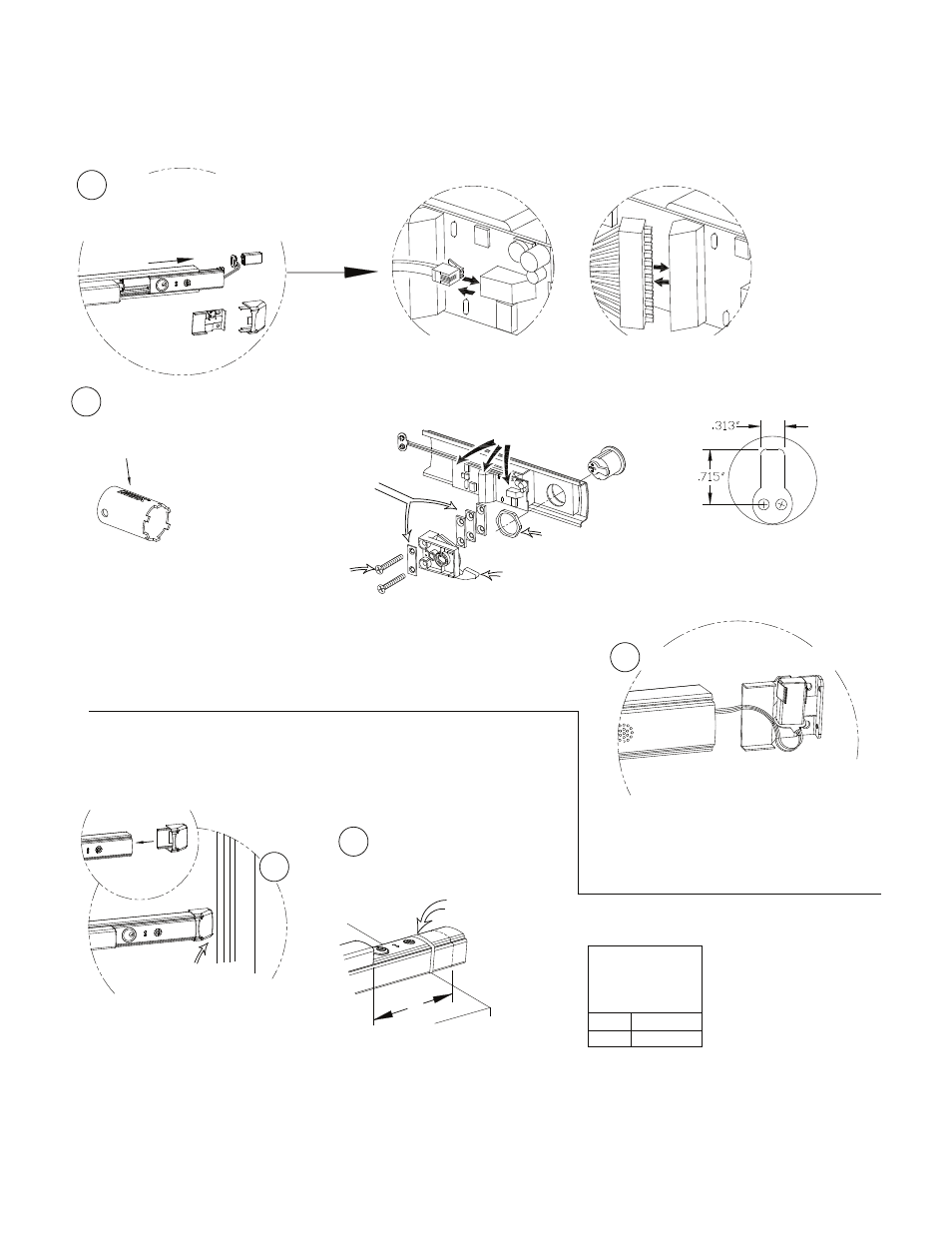

Mortise cylinder installation, View a view b – Detex Delayed Egress With Magnetic Lock User Manual

Page 2

12 Pin Connection

(note: board layout may differ slightly from layout shown)

CAUTION:

Install mortise cylinder

with hex nut provided

Dogging lever should be in "ON"

(CCW) position before sliding back

into extrusion

NOTE:

(1) Move placement of

spacers to match length

of cylinder used to allow

smooth rotation of cam.

2) All cylinder spacers

must be used, either

on top or bottom

MORTISE CYLINDER INSTALLATION

PRECAUTIONARY NOTES:

1. Be careful when installing fillerplate assembly not to damage modular cable.

2. See "EM ELECTRICAL OPTIONS" before reinstalling filler plate.

Remove endcap, endcap bracket & fillerplate subassembly.

Disconnect cable assembly (view A),

12 pin connector (view B), and battery

Re-connect in the following order:

1) Cable assembly (view A),

2) Battery,

3) 12 pin connector (view B),

Install fillerplate subassembly

& endcap bracket.

RE-INSTALL FILLERPLATE

View A

View B

Modular Cable Connection

1

L

2

Check for device and door

frame clearance.

If no cut-off needed,

proceed to the next page.

Cut fillerplate and extrusion

STRAIGHT & SQUARE to

desired length and deburr

Slide endcap assembly

onto extrusion

Secure with tape

before cutting

CAUTION:

CHECKING FOR DEVICE CLEARANCE

(Cut-Off procedure if required)

For aluminum Advantex finish cutdown applications: After cutting, the baseplate extrusion can be reversed to place

the cut end inside the head cover. To do so, loosen the setscrew inside the aluminum baseplate extrusion and slide

extrusion out, reverse, & slide back in. Tighten setscrew.

Minimum

Fillerplate

Length

Type

Length (L)

9"

EM

Tighten with hand tools only.

Do not overtighten

1

2

3

INSTALL MORTISE CYLINDER

Mortise Cylinder with

standard Yale cam

required

Cylinder nut socket

p/n 103779

(sold separately)

See View A & B

REMOVE FILLERPLATE

104878 Page 2