Troubleshooting guide – Ames Fire & Waterworks 5000RPDA Reduced Pressure Detector Assemblies User Manual

Page 6

6

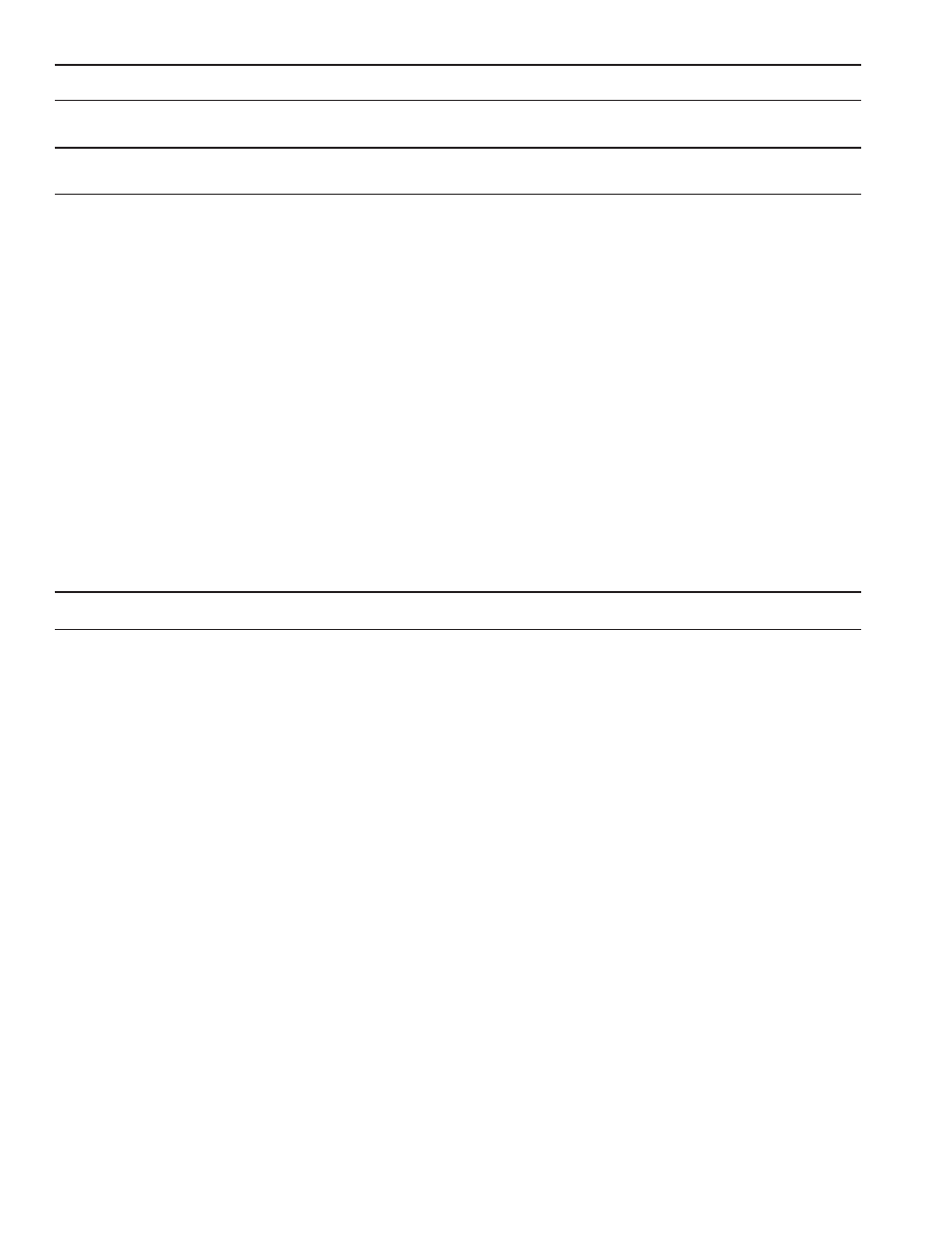

TROUBLESHOOTING GUIDE

SERIES 2000DCA AND 3000DCDC

PROBLEM CAUSE SOLUTION

Check valve fails to hold minimum

Debris on seating area

eliminate debris

leaking gate valve (this is determined repair or replace

separately during the test procedure)

damaged seat

disassemble and replace

damaged clapper plate

disassemble and replace

broken spring

disassemble and replace

CHECK VALVE DISC COMPRESSION (When Using A Duplex Pressure Gauge)

During the ‘initial test’, both the high and low side gauges may drop at the same rate, in which case the check valve would normally be

assessed as leaking. However, after both gauges have fallen approximately 10 – 15psi or more, the high side gauge fi nally drops and

holds the required 2psi below the low side gauge. Even though both gauges originally fell together, the check valve is holding tight. The

reason for this is that the check valve disc is compressing as a backpressure is created. As the high (upstream) pressure is bled off to

drop the 2psi, the downstream pressure begins to push harder on the backside of the check valve. So as the seat imbeds further into the

elastomer disc, the volume on the backside of the check valve increases. With an increase in volume there is a corresponding decrease in

pressure. So as the high side gauge is lowered, the disc compression causes a lowering on the low side gauge too. Once the disc stops

compressing, then the high side gauge will drop below the low side gauge and the check valve will show as holding tight.

SERIES 4000RP AND 5000RPDA

PROBLEM CAUSE

SOLUTION

A. Assembly discharged from

Fouled fi rst check

Disassemble and clean No.

differential relief valve during

1 check valve

a no-fl ow condition

Fluctuating inlet pressure

Control supply line water pressure

Outlet pressure higher than inlet

Disassemble clean #2

pressure & leak in No. 2 check valve

check valve & identify cause of back

pressure

Leak thru diaphragm or around

Service relief valve

fl ange Bolt holes of relief valve

(page 8)

Pressure relief valve-does not close

See problem D (pg. 6)

B. Assembly discharges from

No. 1 check valve

Disassemble and clean No. 1

differential relief valve during

wedged open

check valve

a fl ow condition

O-ring displaced from groove

Disassemble and replace

in relief valve

Pressure relief valve -

See problem D (pg. 6)

does not close