Ames Fire & Waterworks LFM300, LFM300N Lead Free Double Check Detector Assemblies User Manual

Installation, maintenance, & repair maxim

RP/IS-A-M200/M300

M200 OSY

NOTICE

For Australia and New Zealand, line strainers should be installed

between the upstream shutoff valve and the inlet of the backflow

preventer.

NOTICE

Due to shipping, storage, and general handling, the Victaulic

Coupling for the shutoff valves may have loosened and should be

retightened during installation.

Testing

For field testing procedure, refer to Ames installation sheets

IS-A-ATG-1 found on

www.amesfirewater.com.

For other repair kits and service parts, refer to our Backflow

Prevention Products Repair Kits & Service Parts price list

PL-A-RP-BPD found on

www.amesfirewater.com.

For technical assistance, contact your local Ames representative.

** Metric Dimensions are nominal pipe diameter. This product is

produced with ASME/ANSI flanged end connections.

www.amesfirewater.com

A Division of Watts Water Technologies, Inc.

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can

result in death, serious personal injury, property damage, or

damage to the equipment.

Keep this Manual for future reference.

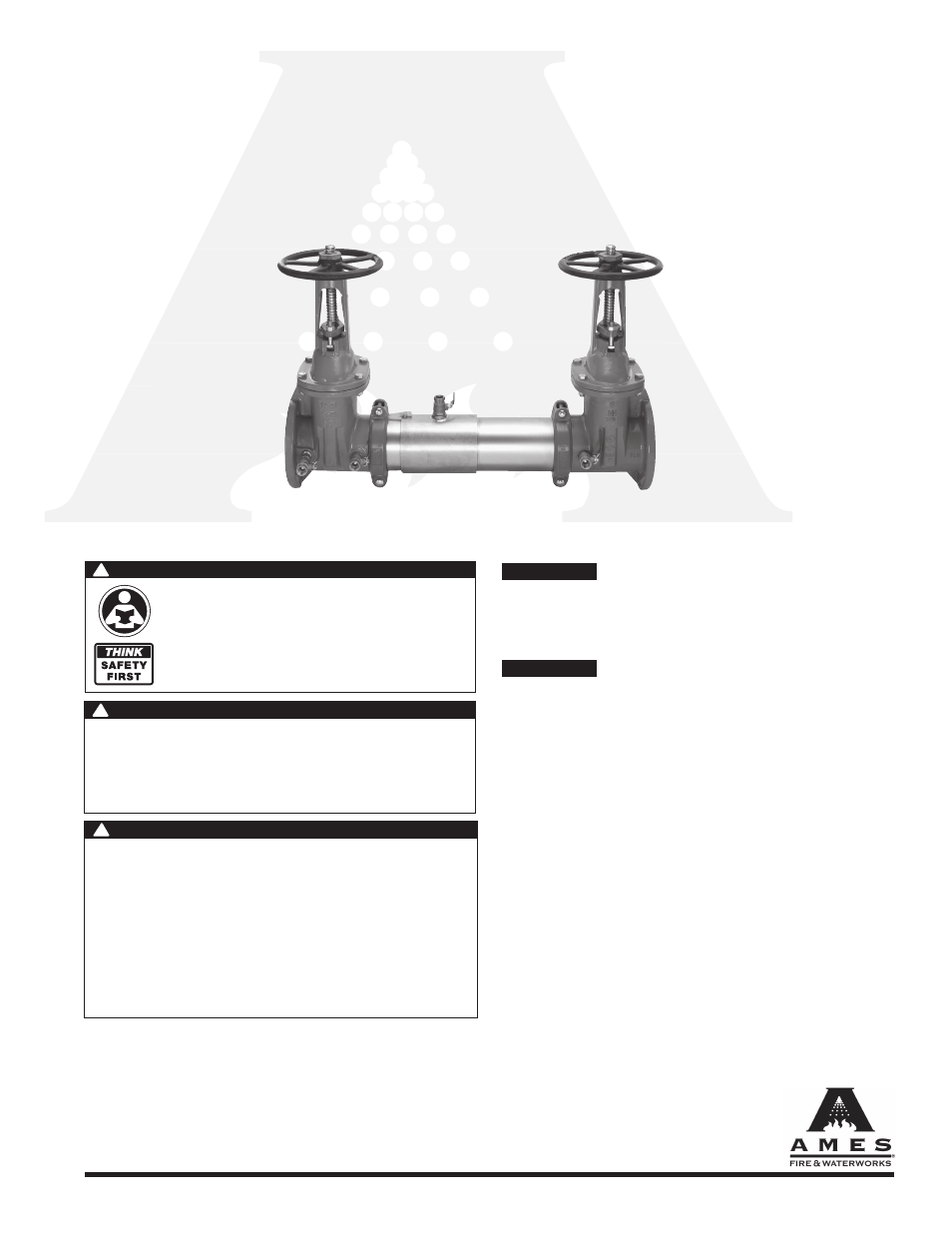

Installation, Maintenance, & Repair

Maxim

™

Series M200, M300, LFM300

Double Check Valve Assemblies

Double Check Detector Assemblies

Sizes: 2

1

⁄

2

" – 10" (65-200mm)**

You are required to consult the local building and plumbing

codes prior to installation. If the information in this manual

is not consistent with local building or plumbing codes,

the local codes should be followed. Inquire with governing

authorities for additional local requirements.

WARNING

!

Need for Periodic Inspection/Maintenance: This product must

be tested periodically in compliance with local codes, but at least

once per year or more as service conditions warrant. If installed on

a fire suppression system, all mechanical checks, such as alarms

and backflow preventers, should be flow tested and inspected in

accordance with NFPA 13 and/or NFPA 25. All products must be

retested once maintenance has been performed. Corrosive water

conditions, and/or unauthorized adjustments or repair could render

the product ineffective for the service intended. Regular checking

and cleaning of the product’s internal components helps assure

maximum life and proper product function.

WARNING

!