Testing procedures – Ames Fire & Waterworks 5000RPDA Reduced Pressure Detector Assemblies User Manual

Page 4

4

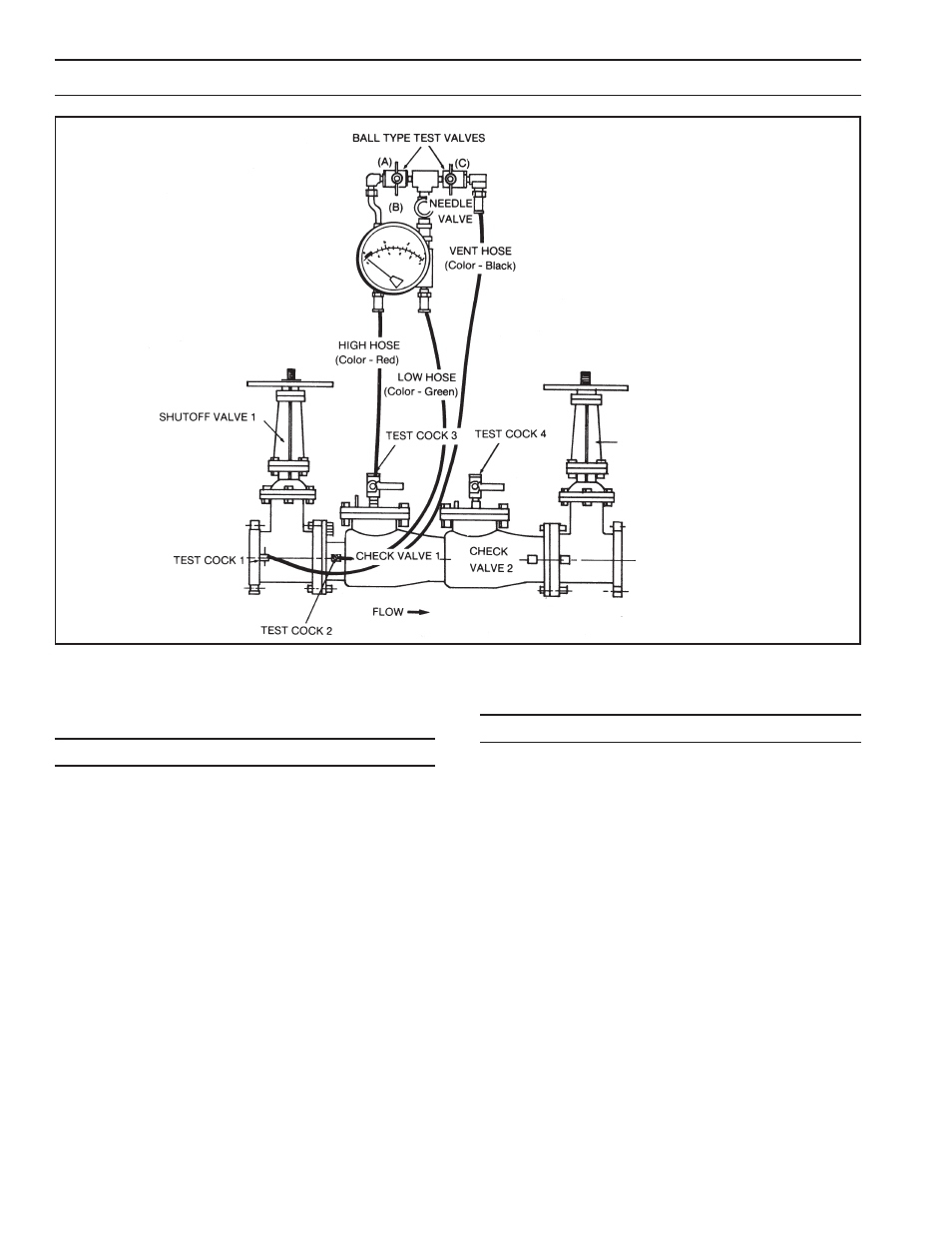

TESTING PROCEDURES:

SERIES 2000DCA AND 3000DCDC

DIAGRAM SHOWS TEST SET-UP

FOR FIRST CHECK

SHUTOFF VALVE 2

Test Number One

Purpose: To test No. 1 check valve for tightness

against reverse fl ow.

TESTING OF NO. 1 CHECK VALVE

STEP NO. 1 Close No. 1 and No. 2 shutoff valves.

STEP NO. 2 Open test cocks No. 2, 3 and 4. Verify

that No. 1 shutoff valve is holding tight by observ-

ing that the discharge of water from test cock No.

2 stops.

STEP NO. 3 Attach test kit “Vent” hose to No. 1 test

cock; “Low” hose to No. 2 test cock and “High” hose

to No. 3 test cock. At this point valves (A) and (C)

should be open and (B) should be closed.

STEP NO. 4 Close test cock No. 4.

STEP NO. 5 Open test cock No. 1. The needle of the

differential gauge will indicate a pressure in excess

of 15 PSID.

STEP NO. 6 Slowly open needle valve (B) until the

differential gauge reads 10 PSID. Then close (B).

The gauge reading will not change if No. 1 check is

holding tight. If No. 1 check is leaking, the gauge will

drop to 0.

Requirements: The check valve shall be tight against

reverse fl ow under all pressure differentials.

TESTING OF NO. 2 CHECK VALVE

STEP NO. 1 Close test cock No. 1.

STEP NO. 2 Open test cock No. 4.

STEP NO. 3 Change “Low” hose from test cock No.

2 to test cock No. 3. Change “High” hose from test

cock No. 3 to test cock No. 4. On the test kit, valves

(A) and (C) should be open and valve (B) should be

closed.

STEP NO. 4 Open test cock No. 1. The pressure

differential gauge will indicate a pressure in excess

of 15 PSID.

STEP NO. 5 Slowly open needle valve (B) until the

gauge reads 10 PSID, then close. If the gauge reading

does not change, No. 2 check valve is holding tight. If

No. 2 check is leaking, the gauge will drop to 0.

NOTE in the above testing: minor leakage in shutoff

valve No. 2 will not affect the test results. However, in

testing the No. 1 check, leaking shutoff valve No. 1

would cause a good fi rst check to fail the test.