See drawing page 15) – Ames Fire & Waterworks 5000RPDA Reduced Pressure Detector Assemblies User Manual

Page 10

10

MAINTENANCE INSTRUCTIONS:

REMOVAL AND REPAIR OF RELIEF VALVE

(See Drawing Page 15)

DRAWING IV

1. Depressurize assembly. Disconnect hose and re-

move relief valve from elbow fl ange. Inspect rubber

relief valve mounting seat gasket for debris, cutting

or distortion of rubber. Remove

5

/

16

" lid bolts.

2. Disassemble piston assembly by unscrewing top

diaphragm plate from seat tube in counter clockwise

direction. Remove O-ring from relief valve body. Clean

and inspect all parts for damage, debris or buildup.

Clean and inspect vent hole in seat tube and O-ring

groove in body.

3. Place small amount of FDA approved lubricant on

O-ring groove, seat tube OD, O-ring guide pin and

diaphragm plate threads. (Do not use petroleum or

solvent based lubricant). Clean O-ring groove on top

washer plate. Hold top washer plate with threaded

side up. Set diaphragm on washer plate with side

marked HIGH PRESSURE SIDE down, install bottom

washer plate with spring guide shoulder away from

diaphragm. Set seat tube on threaded stub of washer

plate and slowly engage threads. Hand tighten seat

tube in clockwise direction.

4. Stretch to 3" diameter and lubricate O-ring and

place in O-ring groove. Place relief valve spring in

body. Place lid with bolts on piston assembly and

thread diaphragm over bolts. Ensure that diaphragm

is not pinched between lid and washer plate. Reas-

semble unit assuring spring is seated over guide and

that tube is carefully pushed through O-ring in body.

Hand tighten bolts. If O-ring has been pushed from

groove, disassemble, inspect for damage, and repeat

assembly.

Clean and place rubber seat mounting gasket in

recess with raised O-ring side out. Before installing

relief valve, slightly open #1 gate valve to ensure hose

if free of debris and debris is washed from main body.

Bolt relief valve to mainline valve and install hose.

Open #1 gate valve and bleed air from all test cocks

and air vents on relief valve.

5. Test assembly.

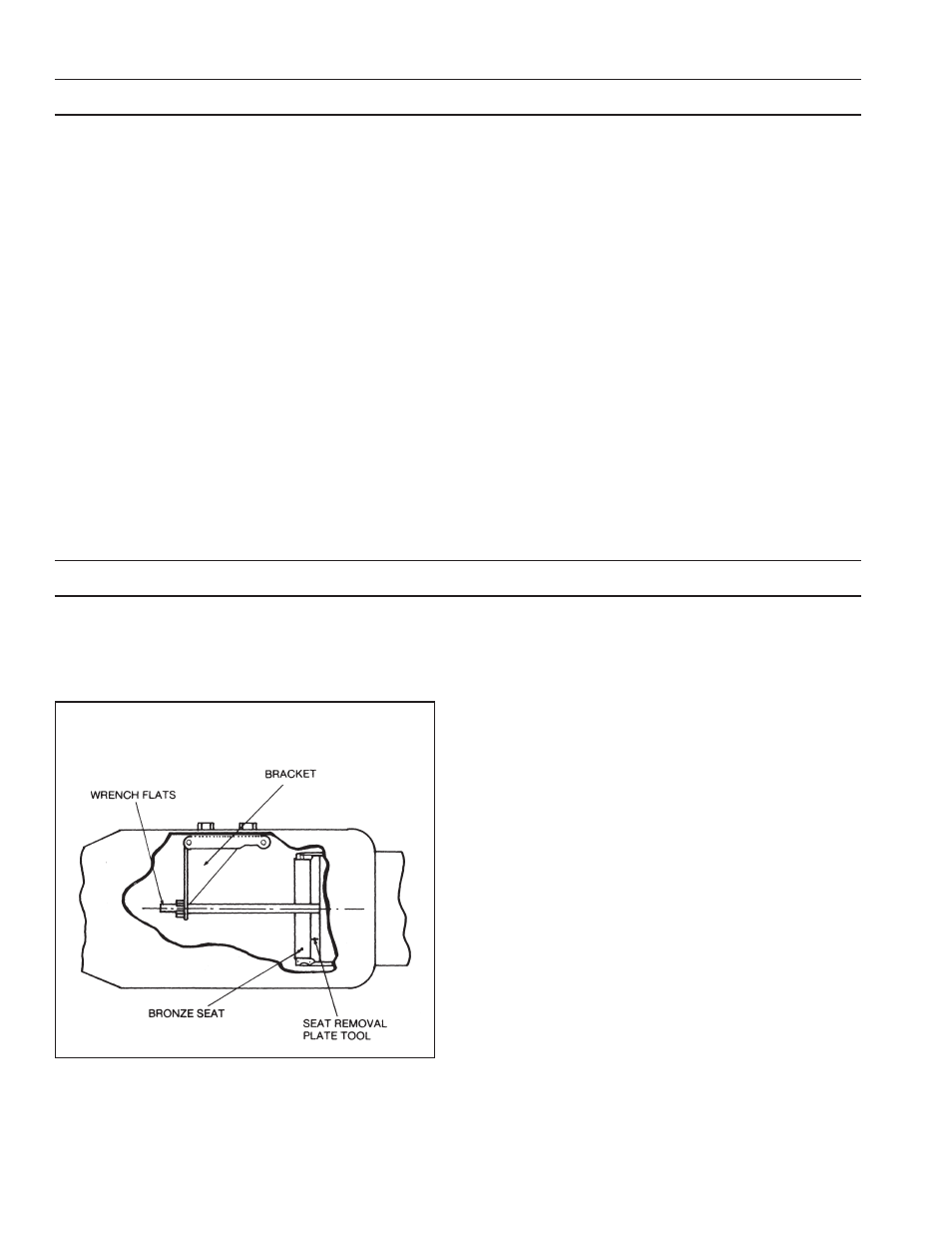

I. Removing Bronze Seat (all assemblies

except #1 RP, 8" and 10" (200-250mm)

DC and DCDC)

1. Remove knuckle joint assembly. (Instructions pg. 8)

2. Insert seat replacement bracket into interior of body

and install where knuckle joint was located.

3. Place seat removal tool beyond seat into pulling

position.

4. Install rod through bracket seat and thread into

seat removal tool.

5. Thread nut and washer onto rod until contact with

bracket.

6. Place wrench on rod fl ats, while using another

wrench to tighten nut until seat dislodges from

body.

7. Remove seat and all tooling except bracket from

body.