4 quality control – Bio-Rad S3™ Cell Sorter User Manual

Page 46

36 | S3 and S3e Cell Sorters

Getting Started

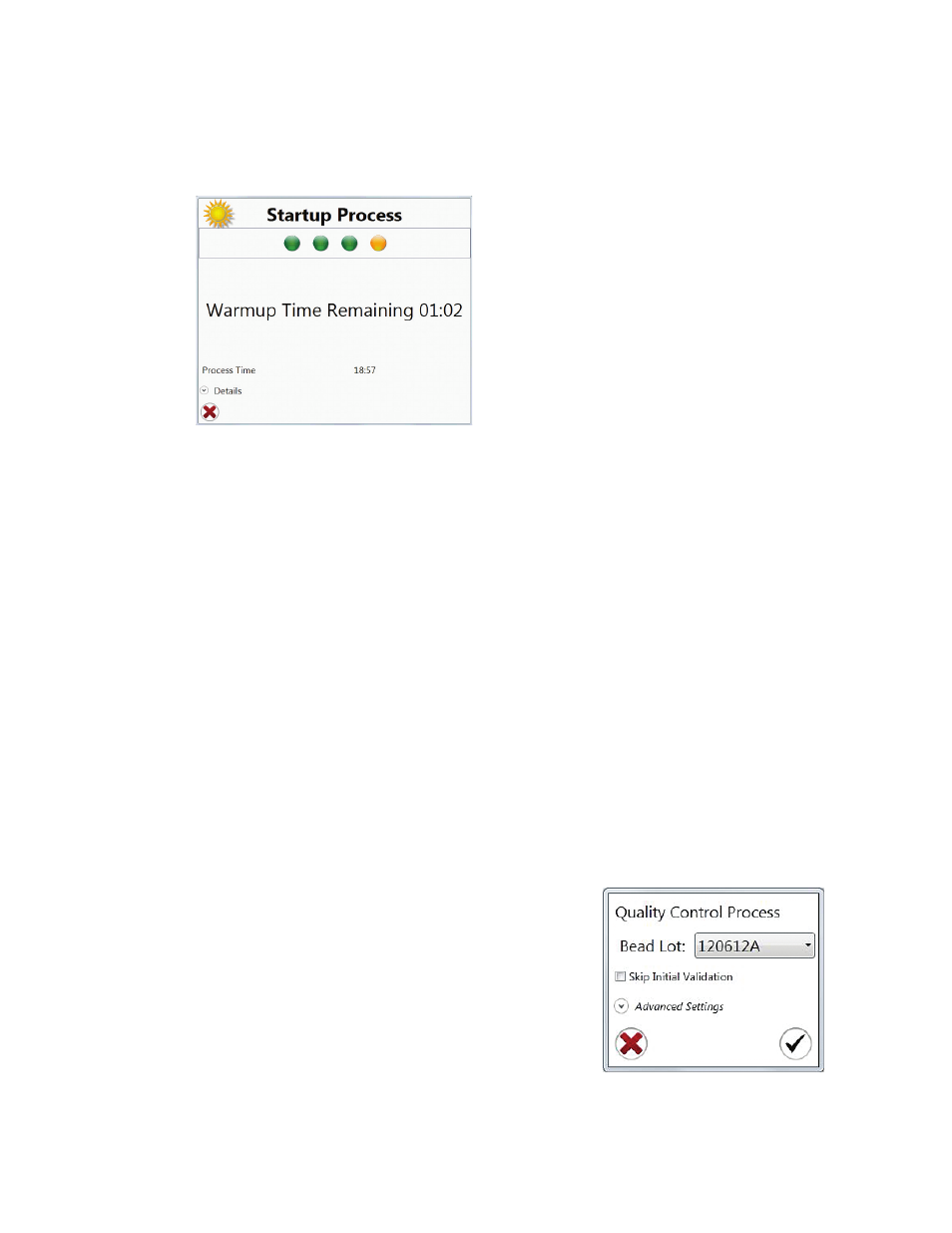

During the startup process, the fundamental alignment window will also open to initiate

cameras, maintain droplets, and align streams to the lasers. The startup process also includes

a warm up period (Figure 34).

After startup completion, both windows will close automatically and buttons in the toolbars will

become available to use.

Note: Automated startup is an option for this instrument. At shutdown, a startup time can be

designated. If this option is selected, be sure to empty the waste container and fill the sheath

fluid and DI containers at the end of the day.

Note: To change the fluidic containers after the software has been initiated or during a run, refer

to Section 5.3, Checking or Swapping Fluidics, for instructions on performing a hot swap.

4.4 Quality Control

The quality control (QC) procedure must be run every day to ensure optimal system

performance. This procedure requires the ProLine

™

calibration beads to adjust alignment, verify

system against the QC criteria, set up droplet creation, adjust side streams, calculate drop

delay, and maintain the droplet break-off.

Note: ProLine Universal calibration beads must be used on a system with a 488/640 nm lasers.

These beads can also be used on the 488 nm or 488/561 nm systems.

To perform the quality control procedure:

1. Vortex a bottle of ProLine calibration beads.

2. Place at least 10 drops (approximately 0.5 ml) into

a 5 ml tube. Do not dilute these beads.

3. Place the tube with beads into the sample input

station.

4. Move the loading stage into the run position.

5. Click Run QC on the Setup and Maintenance tab.

6. Choose the correct bead lot from the dropdown

menu in the Event Based Alignment Settings

window (Figure 35).

Fig. 34. Startup Process window.

Fig. 35. Event Based Alignment

Settings window.