Great Plains 3N-4025P Operator Manual User Manual

Page 80

76

3N-40P

Great Plains Manufacturing, Inc.

196-538M

2014-01-29

Crushing Hazard:

Make all down-stop adjustments with circuit in neutral and

drill raised (actuator plunger not in contact with down-stop).

Loosening the down-stop with circuit active and drill lowered

results in rapid lowering of the frame.

Height Mis-setting Risk:

Make sure the drill is level and the lift system bled and

re-phased before adjusting the tool bar height. If the center

section does not consistently stop at the set height, or the

wings do not run at the same height as the center, the lift

system may have air or be out of phase (above), or the wings

may not be level. See “Frame Alignment and Level” on

page 142.

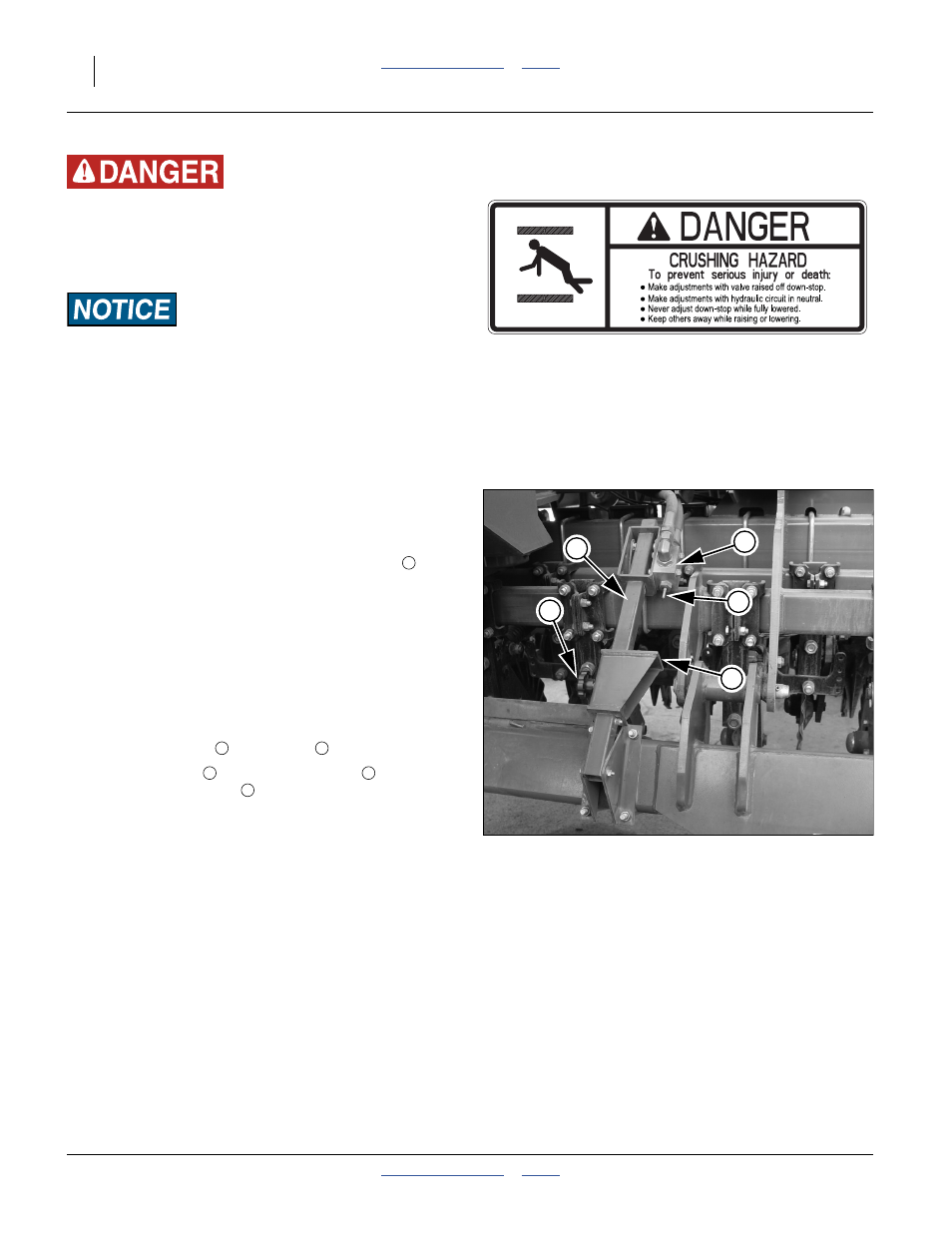

Refer to Figure 94

Note: The change in coulter height is greater than the

change in down-stop adjustment. Make

adjustments in small amounts.

The lift system includes an adjustable stop valve

to fix

the height of the opener frame when the drill is lowered.

To adjust the stop height

(assuming a desired 1

1

⁄

4

inch / 3.2 cm coulter depth):

1.

Move to smooth level ground with soil as similar as

possible to field conditions.

2.

Lower the drill until the coulter blades just touch the

ground. Hold that height by setting the lift circuit to

neutral.

3.

Loosen the knob

on the stop

.

4.

Adjust the stop

position on the tube

until it just

touches the actuator

.

5.

Raise and then fully lower the drill.

6.

Pull forward 10 feet (3 m) and stop.

Figure 94: FMC:

Opener Depth Stop

20274

2

3

1

4

5

1

2

3

3

4

5