10 series disk blade adjustments – Great Plains 3N-4025P Operator Manual User Manual

Page 101

Great Plains Manufacturing, Inc.

Adjustments

97

2014-01-29

196-538M

Refer to Figure 127

An adjuster cam sets row unit spring down pressure

individually for each row unit. This is useful for

penetrating hard soil and planting in tire tracks.

Refer to Figure 128

To adjust down pressure, use the spring adjustment tool

(part 198-126H) stored behind the tool bar at the

Slow-Moving-Vehicle placard.

1.

Raise the drill. Although this adjustment can be

made with the drill lowered, the springs will be in

tension, and will require more effort. The extra force

required may also damage tools.

2.

Put tractor in Park and shut it off.

3.

Position tool in the holes.

4.

Pull upper spring link back.

5.

Move the adjustment cam to the new setting on the

spring adjust bar.

Note: Do not set all rows higher than notch two. Using

high settings across all rows causes uneven

planting. Individual rows may be set higher if

running in tire tracks.

10 Series Disk Blade Adjustments

Opener disc angle and stagger is not adjustable, but

disc-to-disc spacing is, and may need attention as discs

experience normal wear. Spacers will need to be reset

when blades are replaced.

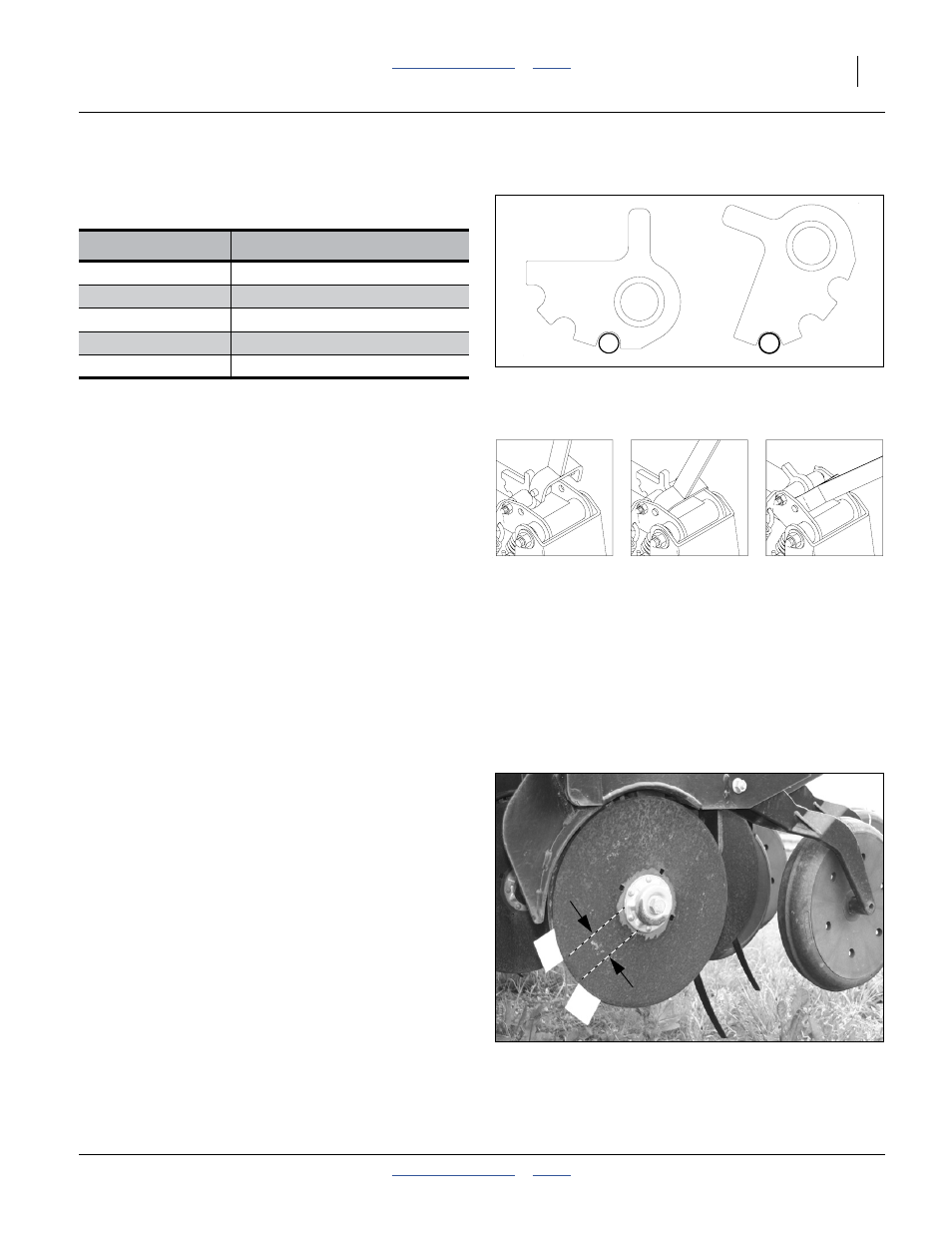

Refer to Figure 129

The ideal spacing causes the blades to be in contact for

about one inch. If you insert two pieces of paper between

the blades, the gap between them should be 0.5 to

1.75 in. (13 to 44 mm).

If the contact region is significantly larger or smaller (or

there is no contact at all), it needs to be adjusted by

moving one or more spacer washers. If the contact

region varies with blade rotation, one or both blades is

likely bent and in need of replacement.

Cam Notch

Pounds

zero (out of notch)

Maintenance Only

one

100 lbs (445 N)

two

116 lbs (516 N)

three

140 lbs (623 N)

tip

Do Not Use

Figure 127: 10P Series:

Row Unit Minimum & Maximum

12104

Figure 128: 10P Series:

Adjusting 10P Series Springs

12105

Figure 129: 10 Series:

Checking Disk Contact

26447