Press wheel stagger, Press wheel centering, 98 7 c – Great Plains 3N-4025P Operator Manual User Manual

Page 127

Great Plains Manufacturing, Inc.

Adjustments

123

2014-01-29

196-538M

Press Wheel Stagger

The factory stagger setting has been found optimal for

residue flow. If your conditions, such as wet soil or

shallow planting, appear to require even press wheels,

you might try one row before re-configuring the entire

drill. To change the stagger:

Refer to Figure 180

1.

Raise the drill and install the lift assist cylinder locks.

See “Lift Cylinder Lock-Up” on page 26.

2.

Remove the bolt

, nut

and lock-washer

for the

left press wheel

.

3.

Move the spacer

and wheel

to the forward of

the two mounting holes at

.

4.

Re-install the bolt, lock washer and nut. Tighten.

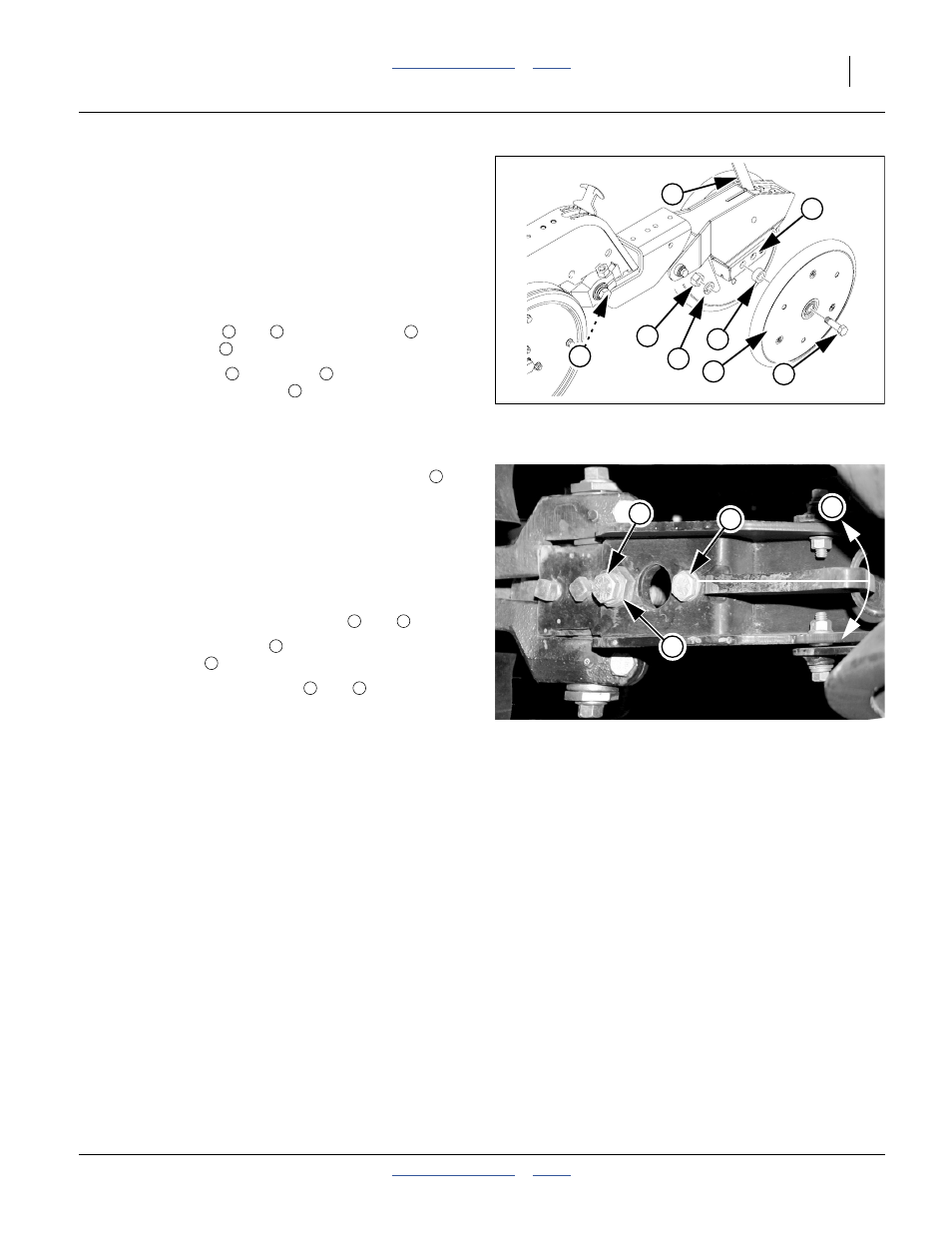

Press Wheel Centering

If one press wheel is running in the seed trench, or the

wheels are not centered over the trench, the angle

of

the press wheel assembly can be adjusted as follows:

Refer to Figure 181

1.

Determine how far, and in which direction, the press

wheel assembly needs to move to center the wheels.

2.

Raise drill and install lift assist cylinder locks. See

“Lift Cylinder Lock-Up” on page 26.

3.

Loosen the

1

⁄

2

inch hex-head bolts

and

.

4.

Turn the hex head cam

under the forward hex

head jam bolt

, and move the required amount.

5.

Tighten both hex-head bolts

and

.

If press wheel adjustments do not provide satisfactory

furrow closing, your conditions may require alternate

press wheels. A variety of wheel assemblies are

available. Consult your Great Plains dealer.

Figure 180

Press Wheel Force & Stagger

22907

a

4

5

3

2

c

1

6

1

2

3

4

5

4

6

Note: Do not loosen the square-head bolts forward of the

hex-head bolts.

Figure 181

Press Wheel Centering

(View from beneath opener)

25277

9

8

7

c

7

8

9

c

9

8

9