Great Plains 3N-4025P Operator Manual User Manual

Page 116

112

3N-40P

Great Plains Manufacturing, Inc.

196-538M

2014-01-29

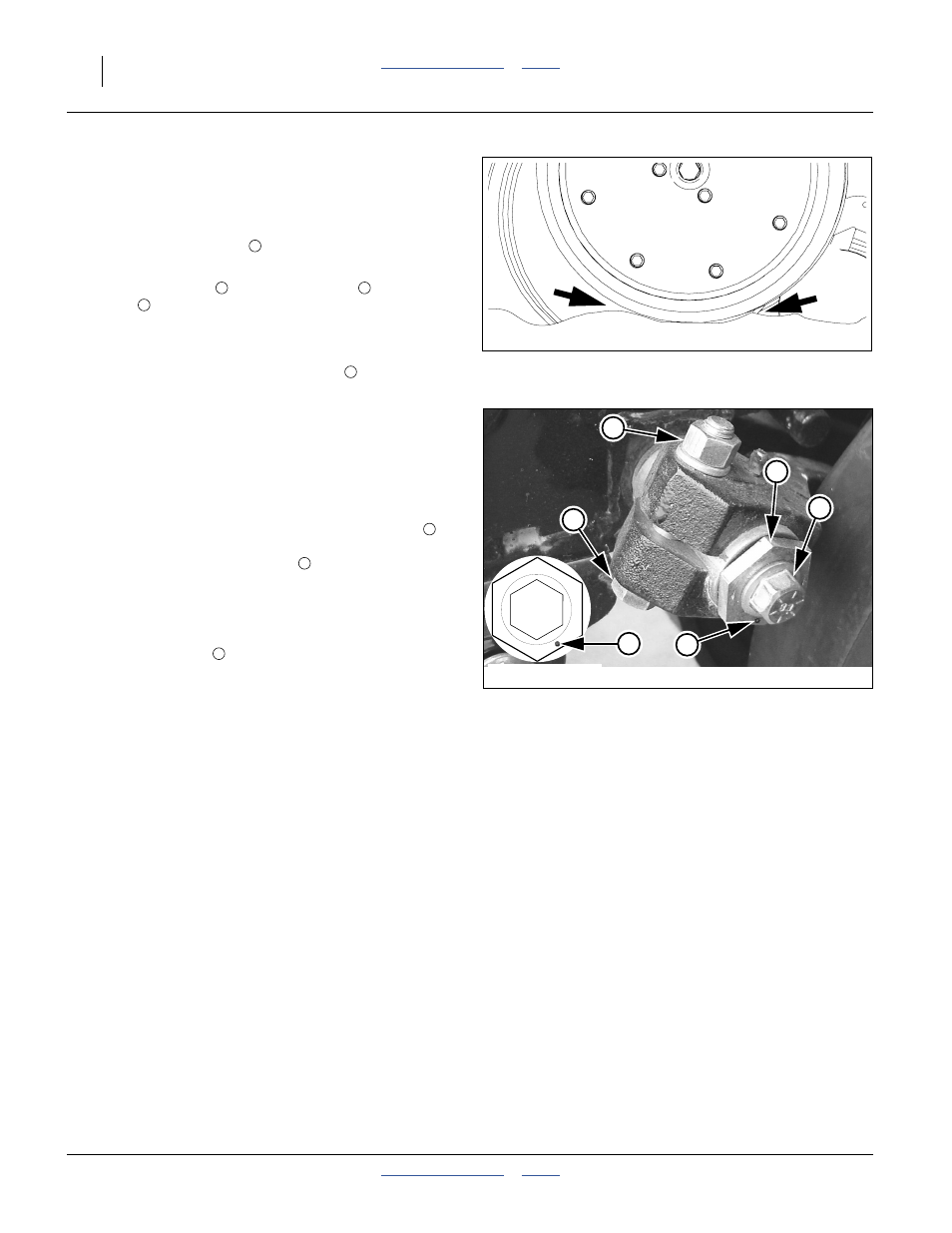

Refer to Figure 157

To adjust side gauge wheels:

1.

Raise planter slightly removing weight from side

gauge wheels.

2.

Loosen hex-head bolt

. Move wheel and arm out

on O-ring bushing.

3.

Loosen pivot bolt

. Turn hex adjuster

so indicator

notch

is at 5 o’clock to 7 o’clock.

Note: Use this as the starting point for adjustment.

4.

Move wheel arm in so side gauge wheel contacts

row unit disk. Tighten hex-head bolt

around bushing and shank.

5.

Check wheel-to-disk contact at 2 inch planting depth.

Lift wheel 2 inch and release. When let go, wheel

should fall freely.

• If wheel does not contact disk at bottom to area where

blade leaves contact with soil, move hex adjuster until

wheel is angled for proper contact with disk.

• If wheel does not fall freely, loosen hex-head bolt

and slide wheel arm out just until wheel and arm move

freely. Retighten hex-head bolt

per grade:

1

⁄

2

inch Grade 5 bolt, 75 ft-lbs.

1

⁄

2

inch Grade 8 bolt, 110 ft-lbs.

6.

Keep turning hex adjuster and moving wheel arm

until the wheel is adjusted properly. When satisfied,

tighten pivot bolt

Note: Use “Torque Values Chart” on page 175 for

reference.

Figure 156: 20 Series:

Opener-Gauge Wheel Contact

22531

Contact Within this Area

1

Figure 157: 20P Series:

Disk/Gauge Wheel Adjustment

22524

22525

Starting Point

4

1

2

3

1

2