Lift cylinder lock-up, Folding the drill – Great Plains 3N-4025P Operator Manual User Manual

Page 30

26

3N-40P

Great Plains Manufacturing, Inc.

196-538M

2014-01-29

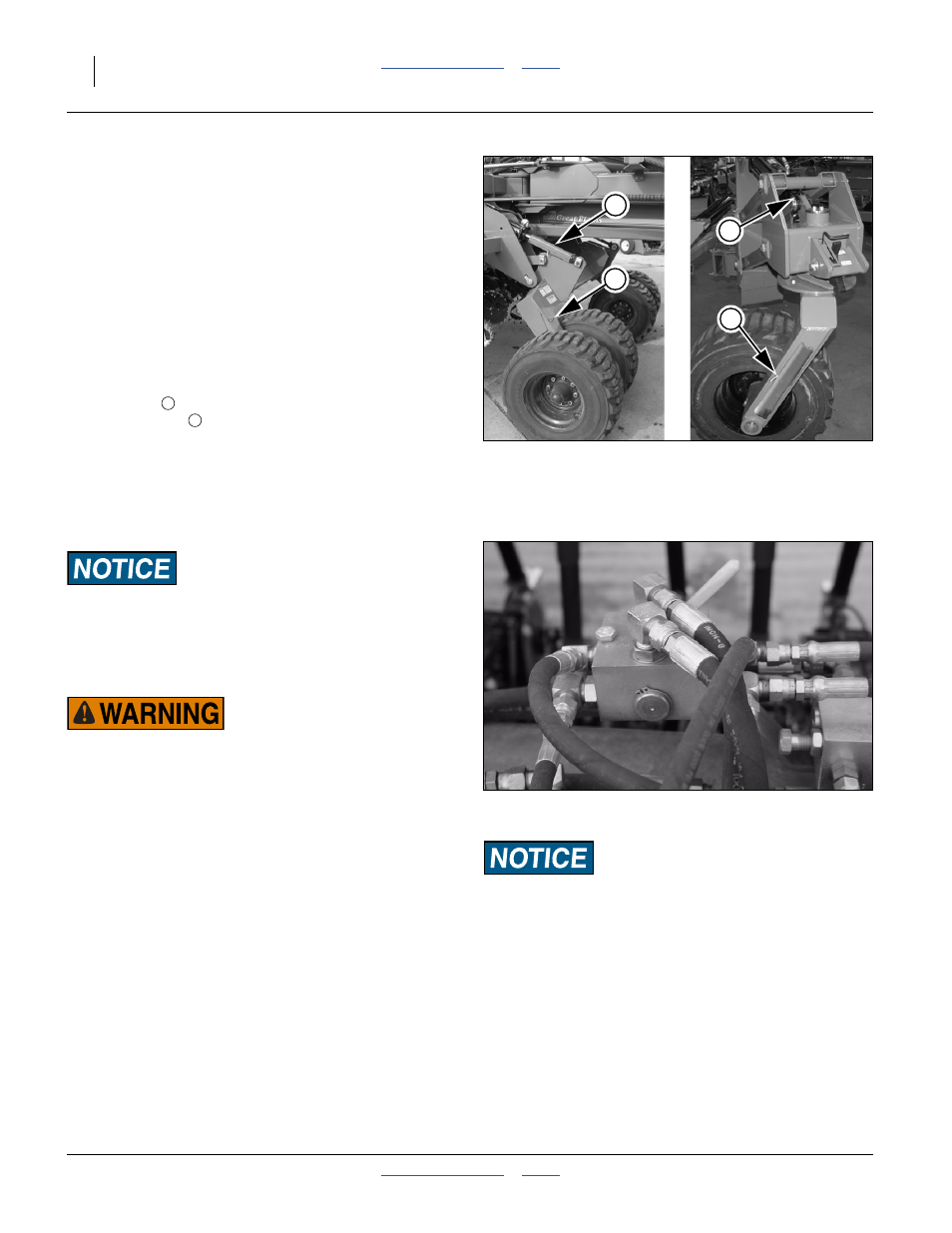

Lift Cylinder Lock-Up

When moving the raised drill more than a short distance,

or over any public road, or when performing adjustments

or maintenance, do not rely solely on the lift cylinders to

keep the mainframe raised.

Install transport locks.

Refer to Figure 25

1.

If drill is folded, confirm hitch is in Float.

If drill is unfolded, hitch may be in any configuration.

2.

Raise the drill mainframe. See “Lift / Lower” on

page 25.

3.

Remove the transport locks from their storage

positions

. Install the transport locks on the

cylinder rods

, securing them with the same pins

used for storage.

4.

Lower the lift cylinders onto the locks.

Folding the Drill

Machine Damage Risk:

Fold only when the drill is raised and locked up.

Fold the drill on level ground with the tractor in neutral.

If your drill has markers, be certain they are folded and

their control switches are off before folding.

Pinch Point and Crushing Hazard. To prevent serious injury

or death:

▲ Always use transport lift locks when drill is folded.

▲ Fold only if hydraulics are bled free of air and fully charged

with hydraulic oil.

▲ Stay away from frame sections when they are being raised

or lowered.

▲ Keep away and keep others away when folding drill.

Refer to Figure 26

1.

Set Drive/Lock selector valve to Lock.

Figure 25

Lift Cylinder Locks Installed

29283

1

1

2

2

1

2

Drill Center section moves back while folding. Tractor may

move forward. Allow at least 10 feet (3 m) clearance behind

drill and ahead of tractor when folding.

Figure 26

Fold: Drive/Lock Selector Valve

21844