Openers – Great Plains PT1230 AA1062 Operator Manual User Manual

Page 49

47

Section 7 Maintenance and Lubrication

PT1230 Pull-Type Folding Planter 401-069M-A

10/10/12

Great Plains Mfg., Inc.

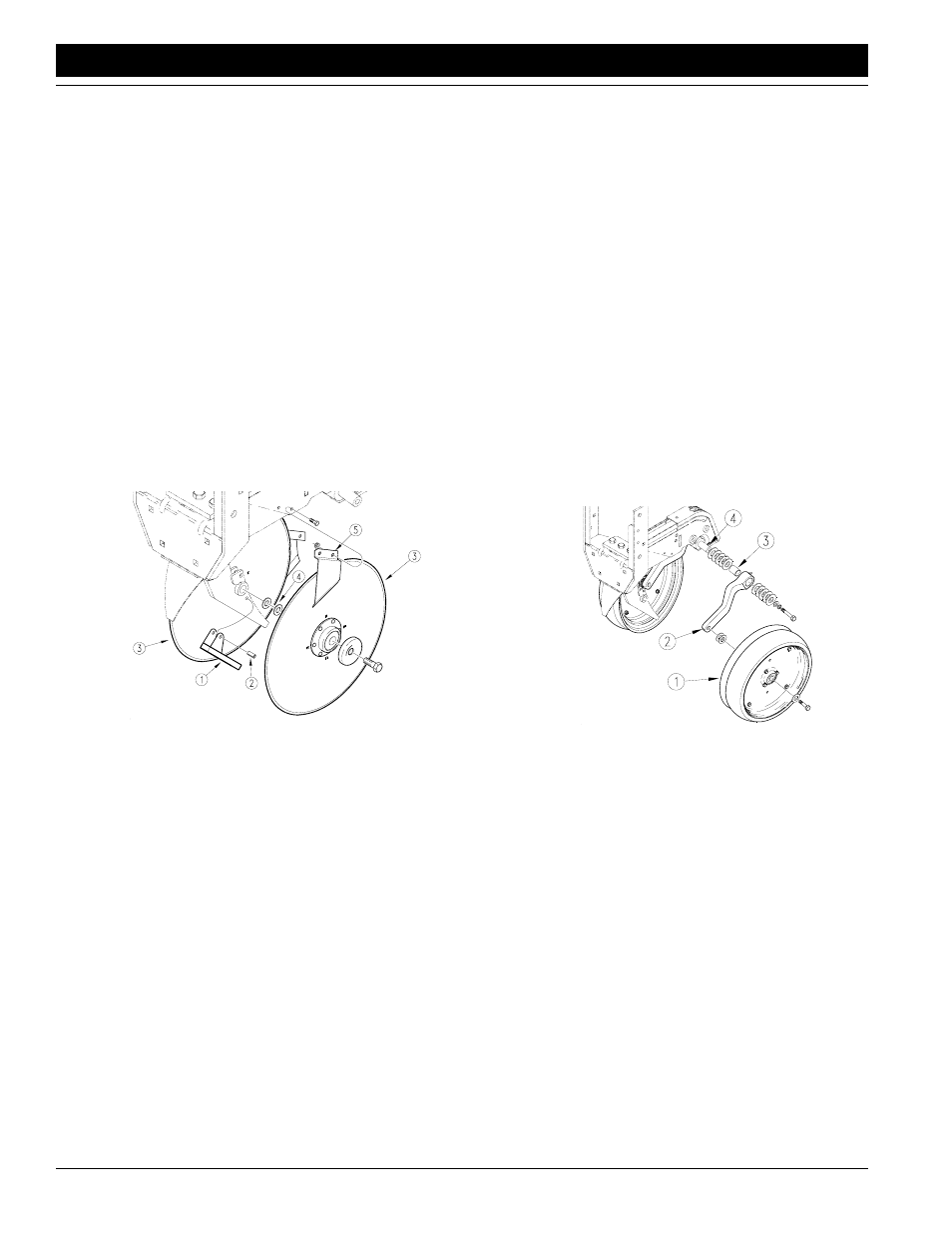

Openers

1.

With the unit raised, check the blade scraper (1) for

wear. Replace the scraper if it is 1/2 inches wide or

narrower. To replace, remove a side gauge wheel and

disk blade. Drive out the roll pin (2) and install a new

scraper.

2.

Check the disk blades (3) for wear. To maintain proper

planting depth, replace if worn to a diameter of 14 1/2

inches or less.

3.

When re-installing disk blades, put three shims be-

tween the bearing and cast-iron shank on one blade.

Tighten bolt. On the opposite side, re-install blade with

two (4) shims between the bearing and cast-iron

shank. Tighten bolt.

4.

Check that the outside disk scrapers (5) are formed to

the disk blades to help remove any mud. Bend and

twist the scrapers to fit the blades as necessary.

Check outside scrapers for proper adjustment and

wear every 200 acres. Replace outside scrapers as

necessary.

16846

Opener Maintenance

Figure 7-12

5.

Check the contact point between the two disk blades.

Place a piece of paper in the top gap between the

disks blades. Bring the paper down until it stops. In the

lower gap place another piece of paper. Bring up until

it stops. Measure the distance between the two pieces

of paper. The distance must be between 1/2 and 1 3/

4 inches. Add or remove shims as needed to get the

correct contact point.

6.

Check for the correct number of shims between the

side gauge wheel (1) and the wheel arm (2). There

must be at least one shim between the wheel bearing

and arm. When installed, the wheel should turn freely

and not hit the arm at the curve. Do not add any more

shims than necessary.

7.

Disassemble the side-gauge-wheel arm (2) from the

row unit. Check the arm and bushing (3) for build up of

grease and dirt in the grease groove. Clean as need-

ed. Re-install as follows:

a.

Place the bushing (3) on stem sticking out of row

unit (4).

b.

Place at least three shim washers over bushing.

c.

Slide the gauge wheel arm on the bushing, push-

ing it up to the shims.

d.

Place shim washers on the bushing until even with

the end of the bushing.

e.

Secure side gauge wheel to arm with a 1/2-inch

bolt, lock washer and flat washer. Tighten to 76

foot-pounds.

16847

Side Gauge Wheel Assembly

Figure 7-13

f.

Check the distance between the side gauge

wheel and the disk blade at the bottom of the

wheel and blade. The distance between the wheel

and blade must be no greater than 1/8 inch. Place

the T- handle in the lowest hole possible, then lift

the wheel and arm. When let go, the wheel should

fall freely. If the wheel is not close enough to the

blade or the wheel does not fall freely, reposition

shims until corrected.

8.

Install the arm and the shims onto the spindle. Tighten

1/2" bolt to the correct torque value as listed in the

Torque Values Chart in “Appendix” on page

9.

Check clearance or contact of the tire and disk. The

gauge wheel should fall freely when lifted. Repeat

steps 1 through 4 if necessary.