Great Plains PT1230 AA1062 Operator Manual User Manual

Page 42

40

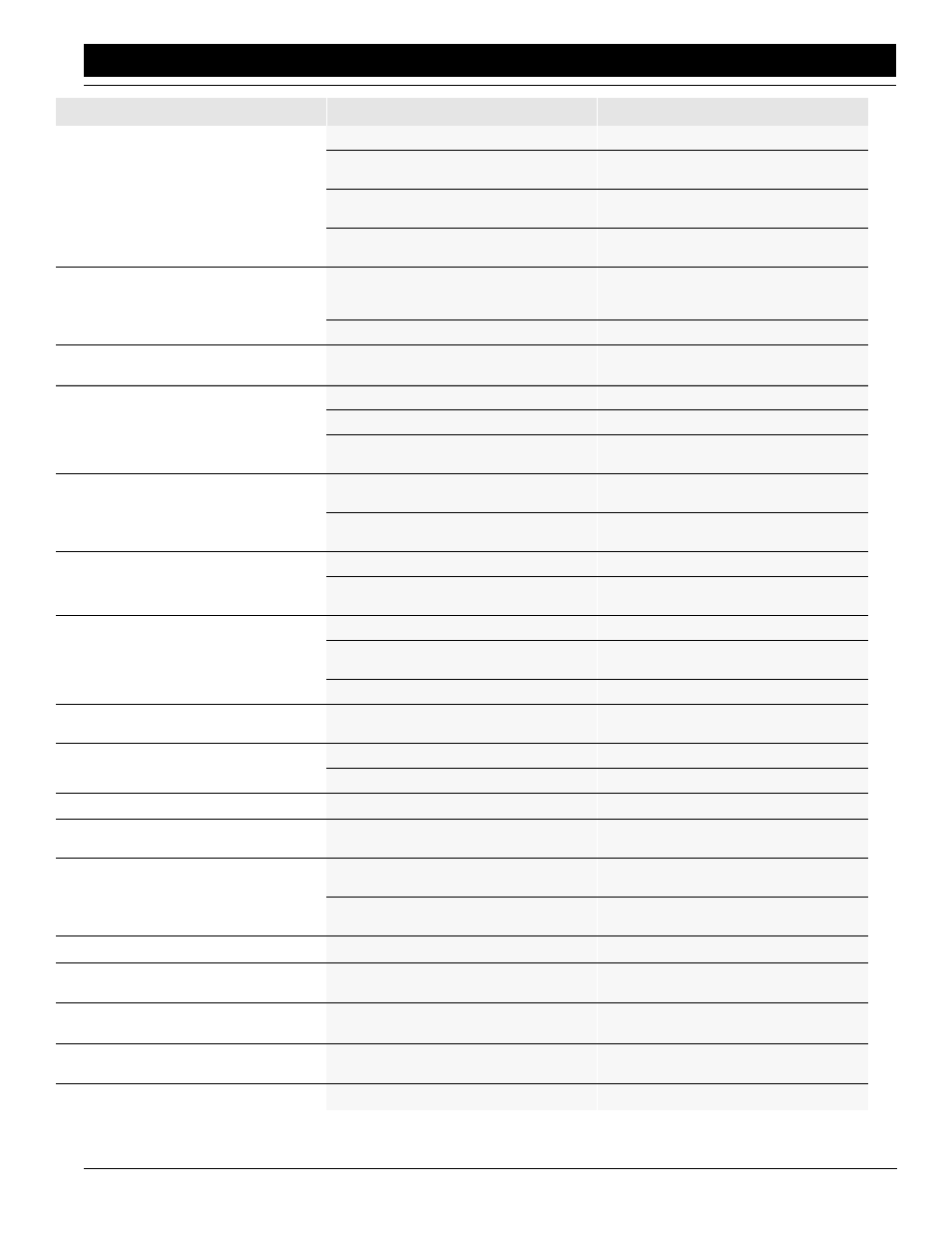

Section 6 Troubleshooting

10/10/12

PT1230 Pull-Type Folding Planter 401-069M-A

Great Plains Mfg., Inc.

Low population count with brush meter.

Meter rpms too high.

Reduce planting speed.

Lack of lubrication causing seeds not to release

from seed disc properly.

Use graphite as recommended.

Seed size too large for seed disc being used.

Switch to smaller seed or use proper seed disc.

See Brush Meter on page 19.

Seed treatment buildup in brush meter.

Reduce amount of treatment used and/or thor-

oughly mix treatment with seed.

Low count at low rpms and higher count

at higher rpms with brush meter.

Foreign material lodged in upper retaining brush.

Remove seed disc and remove foreign material

from between brush holder and bristles. Clean with

compressed air.

Worn upper retaining brush.

Replace brush.

Low count at higher rpms and normal

count at low rpms with brush meter.

Seed disc worn in agitation groove area.

Replace seed disc.

High population count with brush meter.

Seed size too small for seed disc.

Switch to larger seed or proper seed disc.

Incorrect seed rate transmission setting.

Reset transmission.

Upper brush too wide (fanned out) for small seed

size.

Replace upper brush.

Upper retaining brush laid back on brush

meter.

Seed treatment buildup on brush.

Remove brush and wash with soap and water. Dry

thoroughly before reinstalling.

Buildup of foreign material at base of brush.

Remove brush holder and brush. Clean with com-

pressed air and reinstall.

Seed tubes and/or openers plugging.

Allowing planter to roll backward when lowering.

Lower planter only when tractor is moving forward.

Turning tractor steering wheel when planter is down

and stationary. (Four Wheel Drive tractors only.)

Avoid turning tractor when planter is down and sta-

tionary.

Inconsistent seed depth.

Rough seed bed.

Adjust down pressure springs.

Partially plugged or improperly installed seed tube.

Inspect and clean. Ensure seed tubes are hooked

properly in unit shank.

Seed tube improperly installed.

Install properly.

Planter will not lower.

Pressure and return hoses not fully engaged in

SCV outlets

---

Planter frame raises or lowers slowly.

Lower tractor hydraulic pressure.

Tractor standby pressure must be a minimum of 15.

SCV not in fast position.

---

Erratic or uneven lift.

Air in hydraulic system.

Remove air.

Planter will not raise.

Tractor SCV bypassing oil.

Readjust SCV lever linkage. (See Tractor Opera-

tor’s Manual.)

All row units not planting on planter.

Bolt in countershaft sprocket to seed transmission

sheared.

Repair cause of pin shearing and replace cotter

pin.

Loss of power to point row clutches

Check control box, wiring and fuses. See control

box schematic in Figure 6-1 on page 42.

Right or left side does not plant.

Loss of power to point row clutches.

Check wiring and fuses.

Closing wheels leave severe imprint in

soil.

Too much spring force.

Adjust closing wheel spring.

Closing wheels not firming soil around

seed

Insufficient spring force.

Adjust closing wheel spring.

Closing wheel running on top of seed fur-

row.

Improper centering.

Realign.

Closing wheels not applying equal force.

---

Relevel.

Problem

Possible Cause

Solution