Seed hopper, Chemical hopper – Great Plains PT1230 AA1062 Operator Manual User Manual

Page 23

21

Section 3 Row Unit Operation

PT1230 Pull-Type Folding Planter 401-069M-A

10/10/12

Great Plains Mfg., Inc.

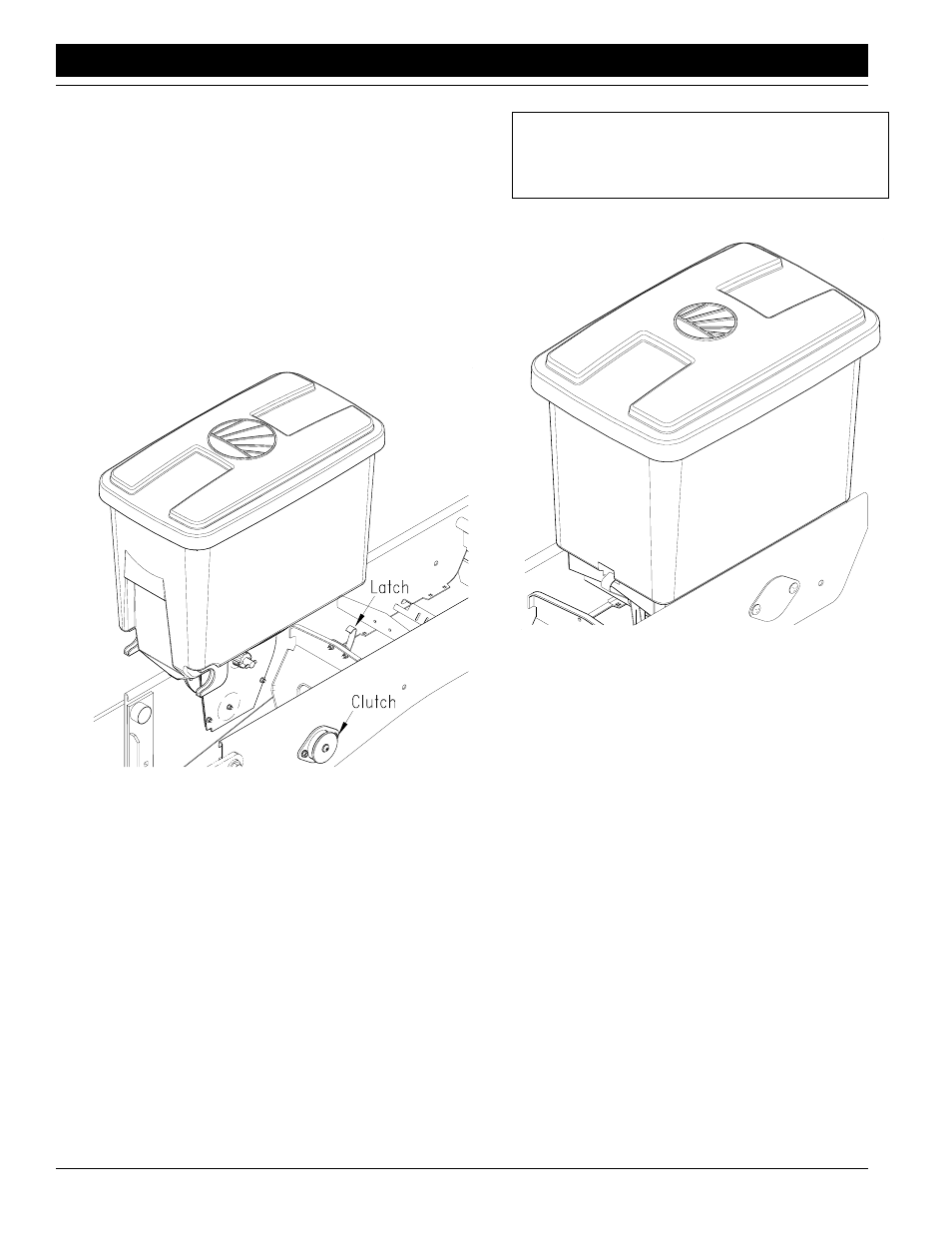

Seed Hopper

The row unit is equipped with one 2-bushel translucent

seed hopper.

Before filling the seed hopper, clear it of foreign objects.

After filling the hopper with clean seeds always replace the

hopper lid. Operating with the lids attached prevents ob-

jects from entering the hopper and also aids in keeping out

moisture.

Empty the contents of the hopper periodically to avoid the

collection of dirt and other materials. To remove the hop-

per, disengage the meter drive clutch and the hopper

latch, see Figure 3-8.

Meter Clutch & Seed Hopper Latch

Figure 3-8

15784

Chemical Hopper

The optional chemical hopper, see Figure 3-9, comes in 2

versions:

•

1 chemical meter and an approximately 70 lb. capacity

translucent hopper.

•

2 chemical meters and 1 divider that separates the 70 lb.

hopper into 2 compartments - approximately 35 lbs.

each.

Before filling each chemical hopper clear it of foreign ob-

jects. After filling each hopper replace the hopper lid. Op-

erating with the lid attached prevents objects from entering

the hopper and also aids in keeping out moisture.

IMPORTANT: To install Lock ‘n Load

®

, you must in-

stall lid stiffeners. Stiffeners are available through

Great Plains, part number 403-075K.

Chemical Hopper

Figure 3-9

15807

The application rate is determined by:

1.

The size of the opening on the meter housing assem-

bly.

2.

The travel speed.

The size of the opening is adjustable by turning the knobs

on the rear of the granular hoppers. There are 99 incre-

ments which indicate the relative application rate. The de-

livery rate will increase from 1 through 99. Setting 00

closes the opening completely. A fluted roller delivers the

granular chemical to the adjustable opening.

The granular chemical flows through a given opening size

at a nearly uniform rate regardless or rotor rpm. Therefore,

SPEED has the greatest impact on application rate and re-

sulting chemical concentration in the row.

For example, if planting speed is reduced from 6 to 3 mph,

chemical concentration will nearly double since the deliv-

ery rate through the orifice remains nearly the same while

the distance traveled in a given period of time has been cut

in half. Therefore, twice as much chemical is placed on the

ground due to the decrease in ground speed.

Rotor rpm will minimally change the chemical meter deliv-