Contact drive wheel spring, Meter drive adjustments, Check for vertical alignment – Great Plains PT1230 AA1062 Operator Manual User Manual

Page 27: Check for horizontal alignment, To adjust alignment

25

Section 4 Adjustments

PT1230 Pull-Type Folding Planter 401-069M-A

10/10/12

Great Plains Mfg., Inc.

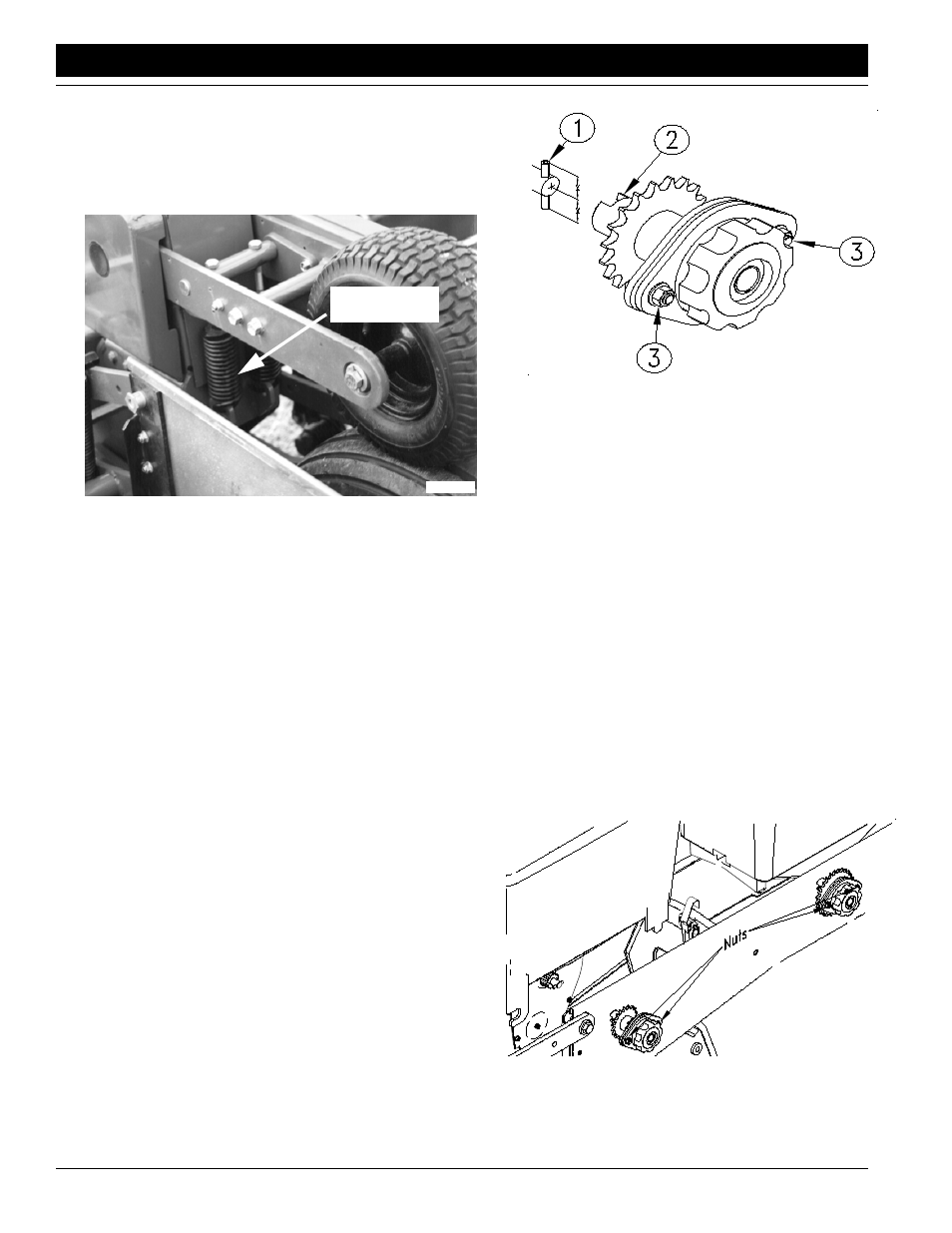

Contact Drive Wheel Spring

There are two down pressure springs, see Figure 4-3, on

each contact drive wheel. The down pressure is factory

preset and should need no further adjustment.

Meter Drive Adjustments

The alignment between the meter clutch and the input

shaft is important. If there is misalignment the meter will

not function properly. Excessive wear and damage can

also occur to the meter housings. When replacing the

meter the vertical and horizontal alignment should be

checked.

Check for Vertical Alignment

Refer to Figure 4-4:

1.

Latch the appropriate hopper into place on the sup-

port.

2.

The roll pin in the end of meter input shaft should be

centered (equal distances of the roll pin should pro-

trude from both sides of the shaft).

3.

Rotate the input shaft so that the roll pin is vertical.

4.

Rotate the drive coupler so that the slots are vertical.

5.

Release the clutch to engage the drive coupler with

the input shaft.

If the alignment is correct the coupler will engage with the

shaft freely and the roll pin will extend equally on each side

of the coupler. Disengage the clutch and check the hori-

zontal alignment.

Contact Drive Wheel Spring

Figure 4-3

15882

Contact Drive

Wheel Spring

Check for Horizontal Alignment

Refer to Figure 4-5:

1.

Latch the appropriate hopper into place on the hopper

support.

2.

The roll pin in the end of meter input shaft should be

centered (equal distances of the roll pin should pro-

trude from both sides of the shaft).

3.

Rotate the input shaft so that the roll pin is horizontal.

4.

Rotate the drive coupler so that the slots are horizon-

tal.

5.

Release the clutch to engage the drive coupler with

the input shaft.

To adjust alignment:

•

With the hopper in place loosen the two 5/16" nuts.

•

Engage the clutch to the meter input shaft.

•

Align clutch with shaft and tighten 5/16" nuts to torque

values in the Torque Values Chart for Common Bolt Siz-

es in “Appendix” on page

Vertical Alignment

Figure 4-4

16869

Horizontal Alignment

Figure 4-5

16870