Planting recommendations, Adjusting granular chemical rates, Liquid fertilizer attachment – Great Plains PT1230 AA1062 Operator Manual User Manual

Page 33: Danger, Drive wheel slippage

31

Section 5 Planting Rate Adjustments

PT1230 Pull-Type Folding Planter 401-069M-A

10/10/12

Great Plains Mfg., Inc.

Planting Recommendations

To get the best planting results, follow these recommenda-

tions:

•

Plant at 5 mph

•

Add 1 teaspoon of graphite to each seed hopper.

•

Maintain tire pressure in the gauge tires and drive tires.

•

Replace worn meter parts.

Drive Wheel Slippage

Another item that may cause the actual rates of seed or

fertilizer to differ from the delivery rates shown in the oper-

ator’s manual is the amount of drive wheel slippage.

While a certain amount of wheel slippage is normal, ex-

cessive drive wheel slippage may cause undesirable

changes in the actual rates.

Excessive drive wheel slippage may be caused by binding

or poorly lubricated parts, misaligned bearings or caked

material in the pesticide or fertilizer hoppers.

In addition, down pressure springs, coulters, tine tooth at-

tachments, or any other attachment that removes frame

weight from the drive wheels, may contribute to drive

wheel slippage and lower than expected rates.

If in-field checks indicate that the planter is planting at a

rate significantly different than the seed transmission rate

chart indicates, investigate the following in the order listed:

•

Ensure that ALL transmission sprockets are set accord-

ing to the rate chart.

•

Excessive unit bounce can cause low population and re-

duced spacing control. Reduce excessive unit bounce

by increasing unit down force, or drive slower.

•

Ensure that the planter drive wheel slippage is close to

normal. Variations in drive wheel slippage can be

caused by crop residue, tire inflation pressure, soil con-

ditions and unit down force.

Adjusting Granular Chemical Rates

The optional chemical applicators are adjusted by

varying the opening on the chemical meter housing. The

field check is very important because temperature, humid-

ity, speed, ground conditions, flowability of chemicals, and

obstructions affect the application rate.

!

DANGER!

Agricultural chemicals can be dangerous if not selected and

handled with care. Always read and follow directions supplied

by the chemical manufacturer.

To adjust the chemical rate do as follows:

1.

Select a setting from the Insecticide/Herbicide Appli-

cation Rates starting on page 36, as a starting point.

2.

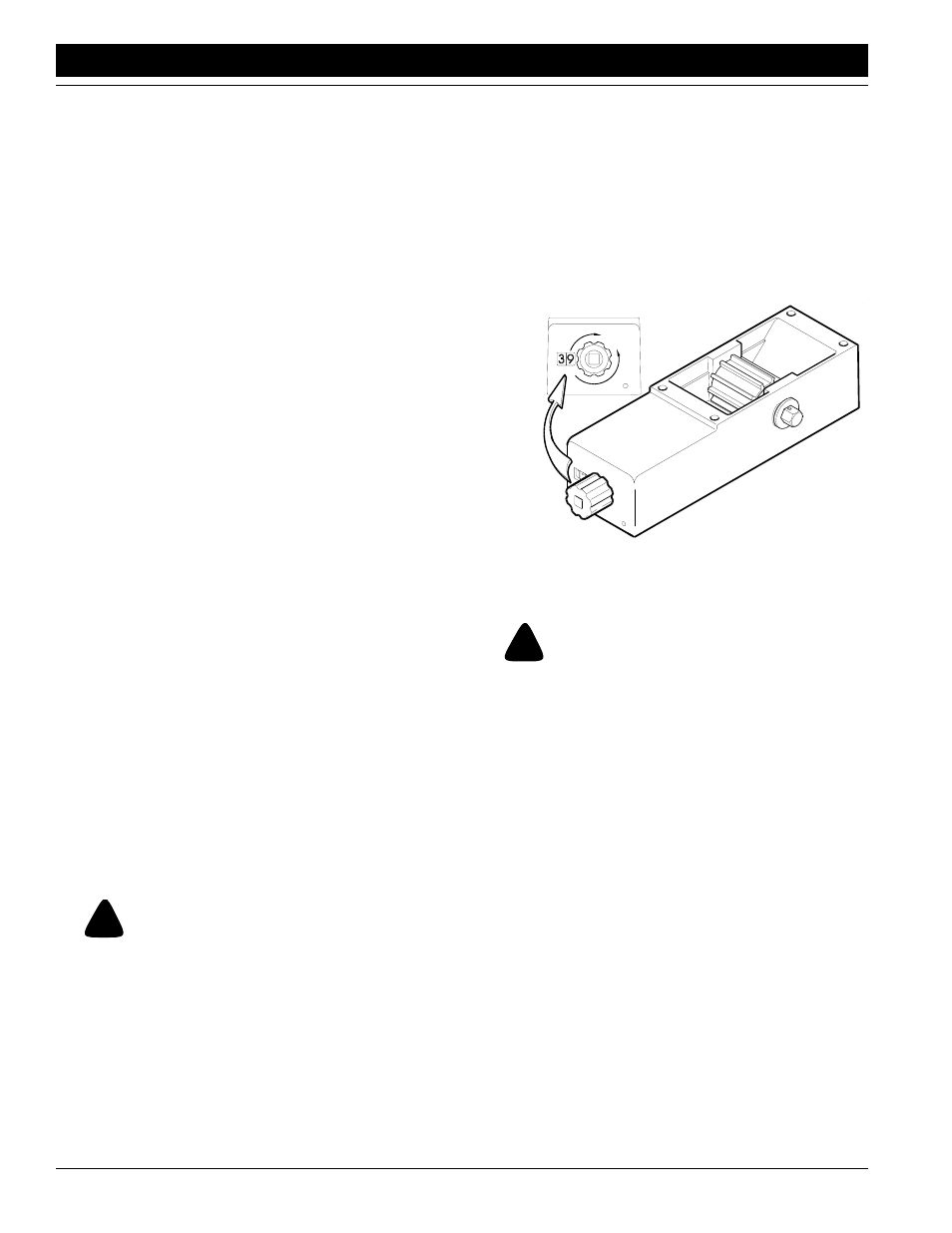

Turn the knob on the chemical meter until the display

shows the appropriate number, see Figure 5-3.

3.

Fill the hoppers with chemical.

4.

Attach a plastic bag to each chemical

diffuser.

5.

Drive 1320’ at a normal planting speed.

6.

Weigh the contents of the bag in ounces.

7.

Multiply ounces by 0.83 to determine the pounds

per acre.

8.

If required, adjust the meter setting and repeat steps 3

through 7 until the desired rate is reached.

Chemical Meter with Knob

Figure 5-3

14914

Liquid Fertilizer Attachment

!

DANGER!

Agricultural chemicals can be dangerous if not selected and

handled with care. Always read and follow directions supplied

by the chemical manufacturer.

On machines equipped with the squeeze pump option, the

rate of liquid fertilizer application is determined by the

combination of sprockets on the squeeze pump driven and

drive shafts. When changing sprocket combinations,

make sure sprockets are in alignment, sprocket retaining

collars are tight and chain tension is sufficiently restored.

The Liquid Fertilizer Rates on page 35 provide an approx-

imate application rate only. Actual delivery will vary with

temperature and the particular fertilizer being used.

NOTE: Certain analysis of fertilizer if placed too close to

the seed may cause germination of seedling damage es-

pecially if used in amounts in excess of fertilizer manufac-

turer’s recommendations. Check with your fertilizer dealer

or manufacturer for the correct amount and placement.