Brush-type seed meter, Daily maintenance, Cleaning brush meter for storage – Great Plains PT1230 AA1062 Operator Manual User Manual

Page 48: Seed disc wear

46

Section 7 Maintenance and Lubrication

10/10/12

PT1230 Pull-Type Folding Planter 401-069M-A

Great Plains Mfg., Inc.

2.

Inspect or replace the seed belt.

NOTE: See Figure 7-10 if belt is replaced. Be certain pad-

dles (A) are oriented as shown. Belt drive wheel (B) may

be removed by removing spring pins (C).

3.

Reassemble in the reverse order.

Finger Meter Belt Orientation

Figure 7-10

15049

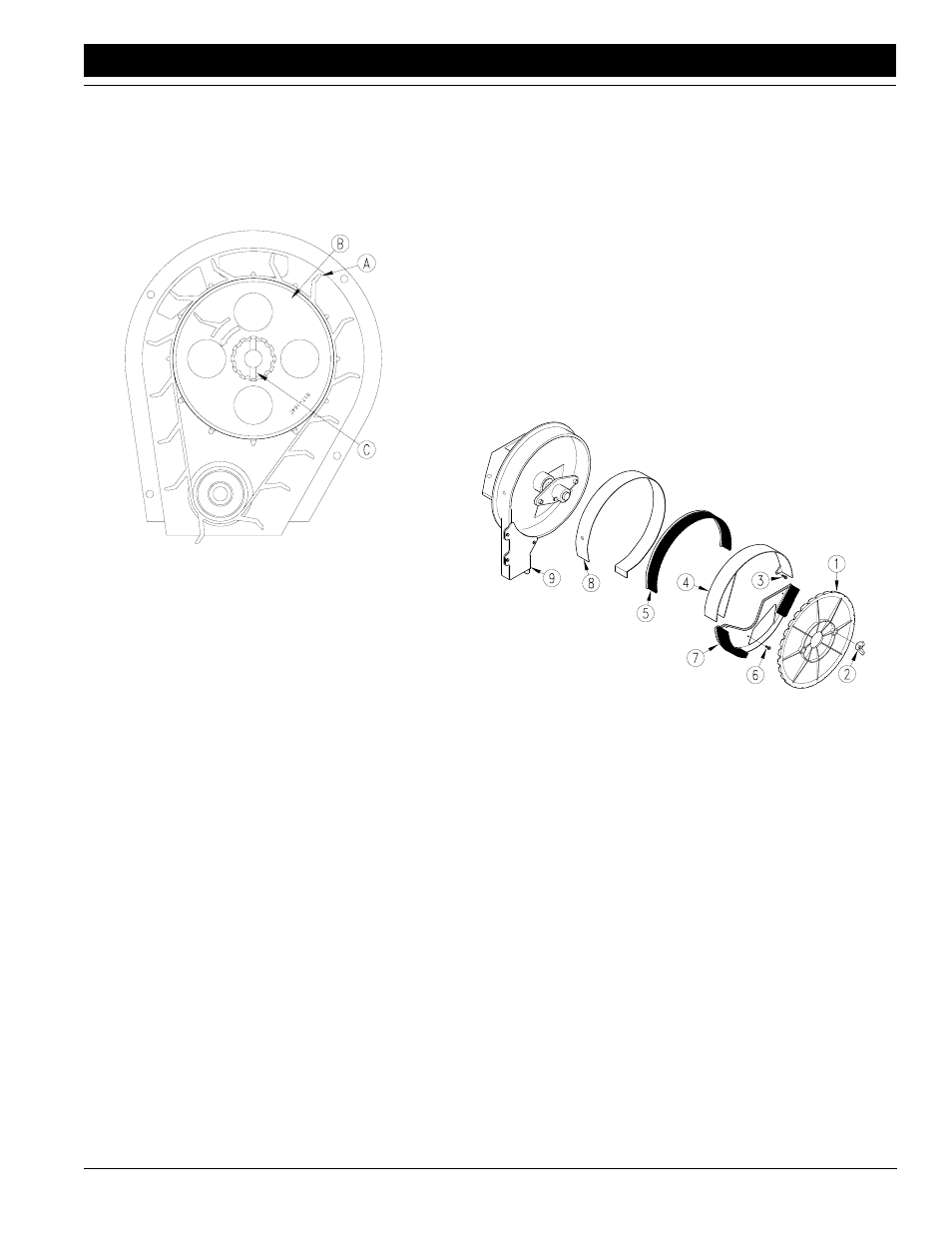

Brush-Type Seed Meter

Daily Maintenance

Inspect the brush meter daily for buildup of foreign materi-

al on the seed disc, particularly in the seed loading slots.

Remove seed disc (#1) by removing the two wing nuts

(#2), see Figure 7-11. Clean the disc by washing it with

soap and water. Check for cracked seed, hulls, etc. lodged

between brush holder and stainless steel wear band.

Clean brush areas of meter housing by using compressed

air.

Cleaning Brush Meter for Storage

1.

Remove brush meter from seed hopper by removing

two 5/16” x 1” long bolts and 5/16” nuts which secure

meter to hopper.

2.

Remove seed disc (#1) by removing the two wing nuts

(#2).

3.

Wash seed disc with soap and water.

4.

Unscrew three hex head screws (#3) from brush hold-

er (#4) and remove brush holder and retaining brush

(#5).

5.

Unscrew three hex head screws (#6) from lower brush

(#7) and remove brush and wear band (#8).

6.

Wash all parts including meter housing (#9) with soap

and water. Dry thoroughly.

7.

Reassemble brush meter in reverse order except for

seed disc.

To install retaining brush (#5) first position brush mak-

ing sure the base of brush is tight against bottom of

meter housing. Install brush holder (#4) and three hex

head screws (#3). Tighten center screw first, then left

screw and right screw last.

8.

Store brush meter and seed disc in a clean, dry place.

Brush Meter

Figure 7-11

15869

Seed Disc Wear

Inspect the seed disc for wear at disc attaching holes,

seed loading slots and seed pockets. Most wear will be

found between seed loading slots.To measure for wear,

lay a straight edge across the surface of disc. Measure the

gap between disc and straight edge. If this measurement

is greater than 0.075” and accuracy is starting to drop off

at higher meter rpms, then replace seed disc.