Calibration for manual gearbox, Calibration crank revolutions – Great Plains NTA3007 Operator Manual User Manual

Page 96

92

NTA907 or NTA3007

Great Plains Manufacturing, Inc.

166-371M

2012-07-02

Calibration for Manual Gearbox

Note: For drills with Variable Rate Kit installed, continue

at “Variable Rate (Servo) Calibration” on

page 95.

Complete step 1 through step 13 beginning on page 90.

14. Set gearbox (page 89): Remove the hairpin cotter

securing the gearbox adjustment crank. Rotate crank

until the control arm indicator points to the scale

setting that matches the rate from the seed rate

chart or as determined by any previous calibration of

a similar material for the same rate.

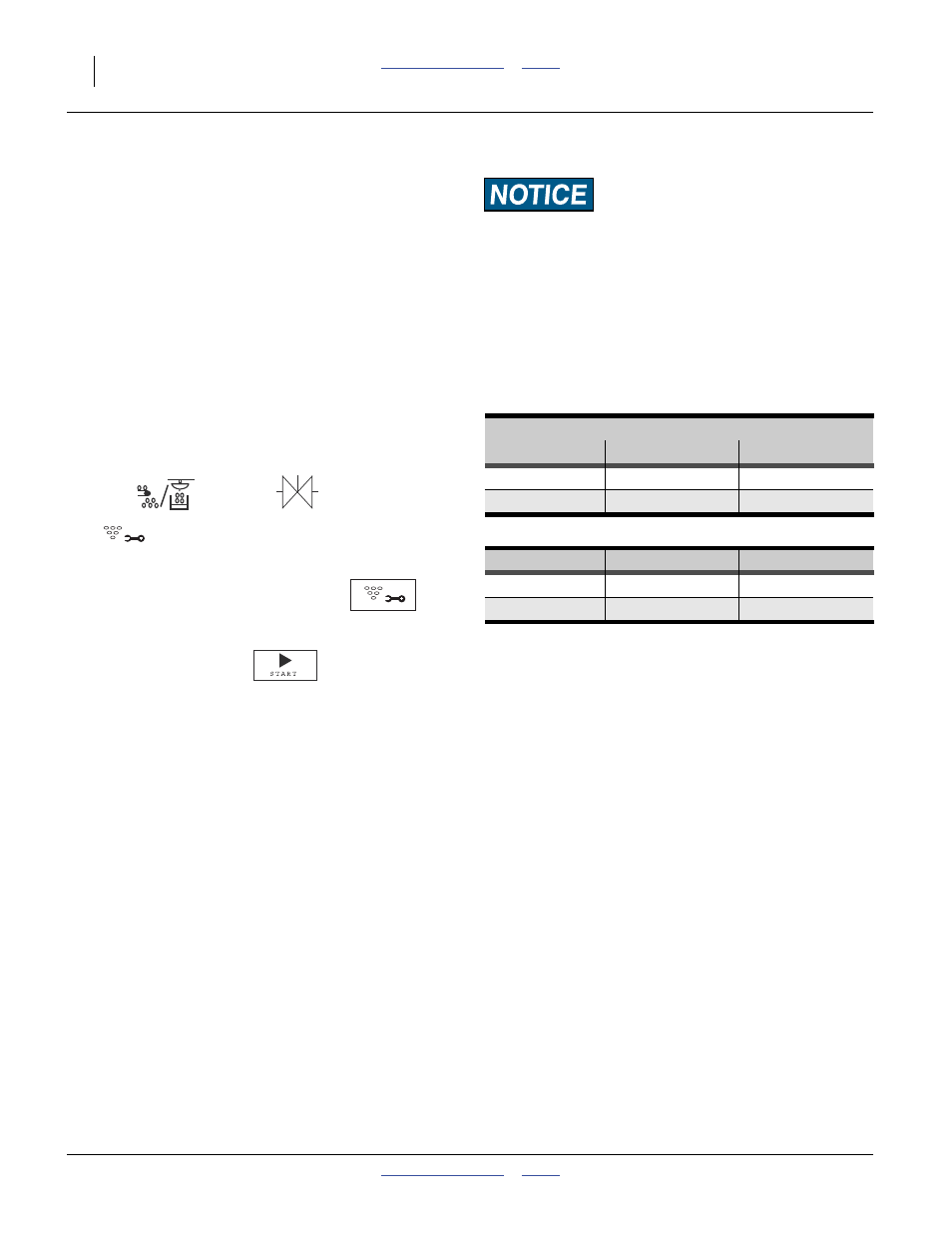

15. Re-insert the hairpin hairpin cotter.

16. Turn the calibration crank, for enough turns to be

sure the meter flutes are full and the system is

metering.

17. Stop cranking. Wipe meter doors. Empty the bag.

18. Push

and then

and then

to get to meter calibration.

19. On the seed monitor terminal,

set the monitor to Calibration mode

.

enter [ 5 ] for the “# Meter Revs”, and

press the Start softkey

.

This “# Meter Revs” parameter does not affect the

monitor calibration because the monitor counts

actual meter shaft revolutions and uses that count to

compute the Calibration Constant.

The “# Meter Revs” parameter is used for a progress

bar displayed during calibration.

20. Turn the hand crank to simulate meter operation for

1

⁄

10

ha or

1

⁄

10

ac. See table at right.

Note: It is important to turn the calibration crank rapidly.

Use a comfortable speed not exceeding

2 revolutions per second, which would simulate

10 km/h (6.2 mph) planting speed. A longer

calibration is always more accurate, especially for

low rates and small seeds.

1

⁄

10

hectare is easy to

calculate and is a minimum calibration run.

See table at right for revolutions per area.

Note: For more accurate results, crank for a full hectare

or acre. With two people, the second person can

observe the revolution count on the seed monitor.

Machine Damage / Invalid Results Risks:

Rotate the calibration crank only in the:

CLOCKWISE direction on drill left, or;

COUNTERCLOCKWISE direction on drill right.

Operating in reverse can cause gearbox damage.

Note: The rate of the arm adjusting crank is more than

one scale degree per turn, and the crank can only

be pinned at quarter turns. Pin it when the

indicator is closest to the desired setting.

Calibration Crank Revolutions

NTA907

Contact Wheel

Revs/hectare

1050

1134

Per 1/10th ha

105

113

Jackshaft

NTA3007

Contact Wheel

Jackshaft

Revs/acre

425

459

Per 1/10th ac

42.5

45.9