Operating the hand crank – Great Plains NTA3007 Operator Manual User Manual

Page 74

70

NTA907 or NTA3007

Great Plains Manufacturing, Inc.

166-371M

2012-07-02

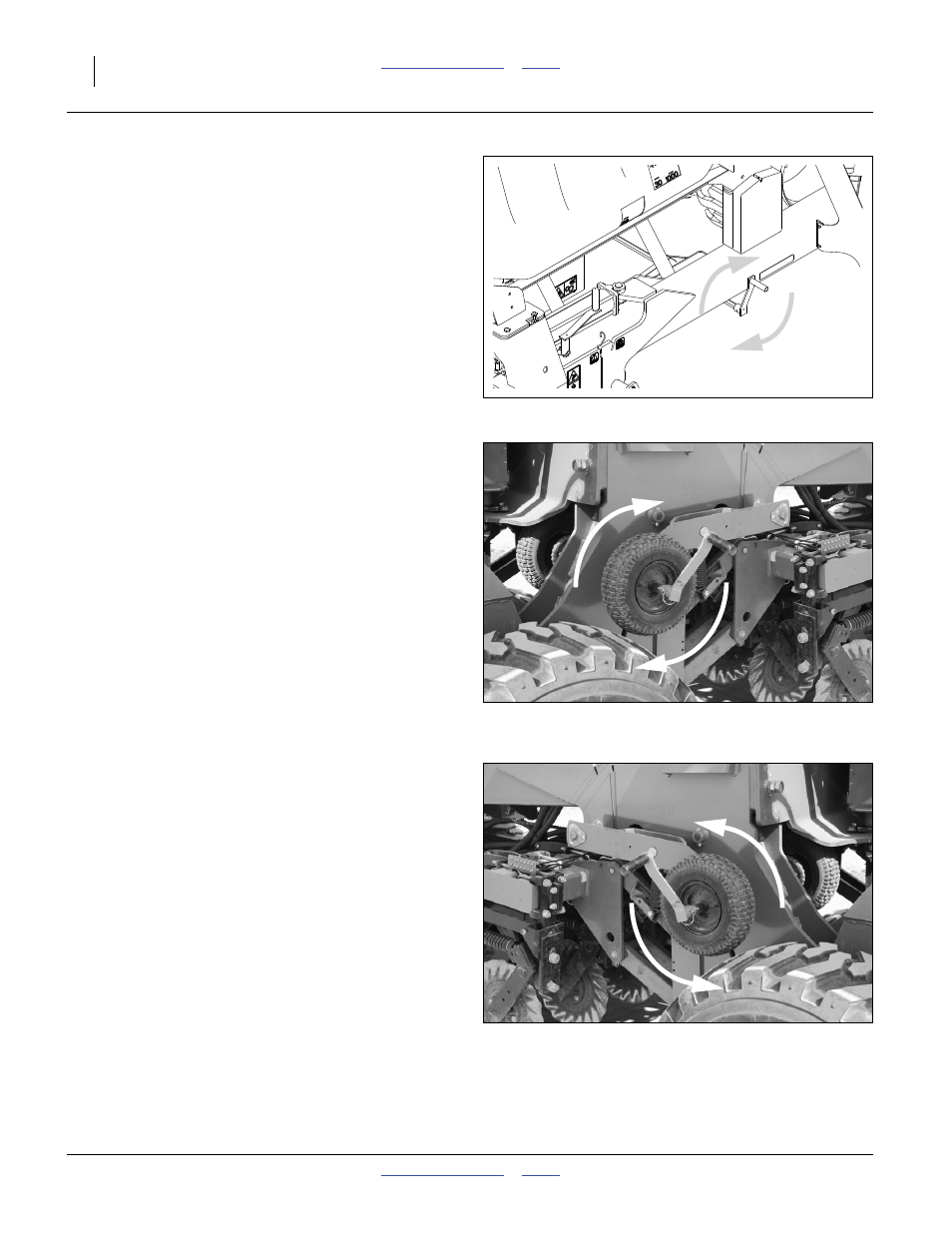

Operating the Hand Crank

Refer to Figure 74 or Refer to Figure 75

1.

Raise drill (page 43). Contact drive tires cannot be

turned by hand with drill lowered.

2.

For more convenient cranking at contact drive

wheels, fold wings (page 44).

3.

For clean-out, set both meters 80 or higher (LOW

range), or 10 or higher (HIGH RANGE).

For calibration, set the meter under test per the

instructions in the Seed Rate Manual, and remove a

DRIVER or DRIVEN final gear on the other meter.

4.

Open calibration door on meter(s) being cleaned-out

or tested.

5.

For front meter, install collection chute (page 68).

6.

For calibration, record weight of calibration bag.

Hook bag to meter or chute under test.

7.

Move crank handle from storage stob to shaft of left

or right outside contact drive wheel.

8.

Turn the hand crank to simulate meter operation

during planting.

9.

Return crank to storage stob at task completion.

Specific recommendations may be made in applicable

manual sections. See: see “Meter Calibration” in the

Seed Rate Manual, “Unloading Materials” on page 77,

and “Storage” on page 82.

In general, you may operate the crank as fast as is

comfortable. For reference, at a field speed of

10 km/h (6.2 mph), the contact drive shaft rotates at

120 rpm (2 turns per second).

For clean-out, make sure the variable rate gearboxes are

set:

• above “10” if the final drive range gears are in High

Range mode, or

• above “80” if the final drive range gears are in Low

Range mode.

To change variable rate gearbox and final drive range

gearing see “Setting Material Rates” on page 84.

Figure 73

Hand Crank Operation, Jackshaft

32395

Figure 74

Hand Crank Operation, Left Wheel

29417

Figure 75

Hand Crank Operation, Right Side

29417