Row unit shut-off, Identify rows to shut off, Close seed shutter – Great Plains YP4025A Operator Manual User Manual

Page 88: Install blank disk

84

YP4025A

Great Plains Manufacturing, Inc.

401-627M

2013-04-24

Row Unit Shut-Off

Skip-row operations, such as planting from every other

row when switching from 30in twin-row to 30in

single-row, requires shutting down unused rows.

Shutting off seeding at a row involves 4 to 7 steps:

1.

Identify the rows to shut off.

2.

Fully close seed inlet shutter (always done).

3.

Replace seed disk with blank disk (always done).

4.

Close seed flow to row at Y-tube (if present).

5.

Lock up row unit to reduce wear (optional).

6.

Reset marker extension (if used, page 167).

7.

Reset monitor active row pattern and row spacing to

avoid nuisance alarms (always done).

Note: Meter drive is not disabled on 25AP row units

during shut-off.

1. Identify Rows to Shut Off

On twin-row planters, openers are installed with short

and long opener mounts. If locking up unused rows of a

twin-row planter, shut off the rear (long mount) rows.

On single-row planters with mid-length mounts, any rows

may be locked up.

2. Close Seed Shutter

Refer to Figure 108 on page 84

Lift the handle

away from the plate. Move it to the top

position, and release the handle into the notch.

Closing the shutter

prevents meter pressurization air

from leaking into the bulk seed air system, resulting in

lower pressures in adjacent rows, with risk of skips.

The shutter also stops seed flow from a row as soon as

the meter is empty. Bulk seed flow to the row falls to nil

as soon as the seed backs up to the air release vent at

the top of the meter. If the row is served by a Y-tube, the

Y-tube also needs to be shut off for the row (step 4).

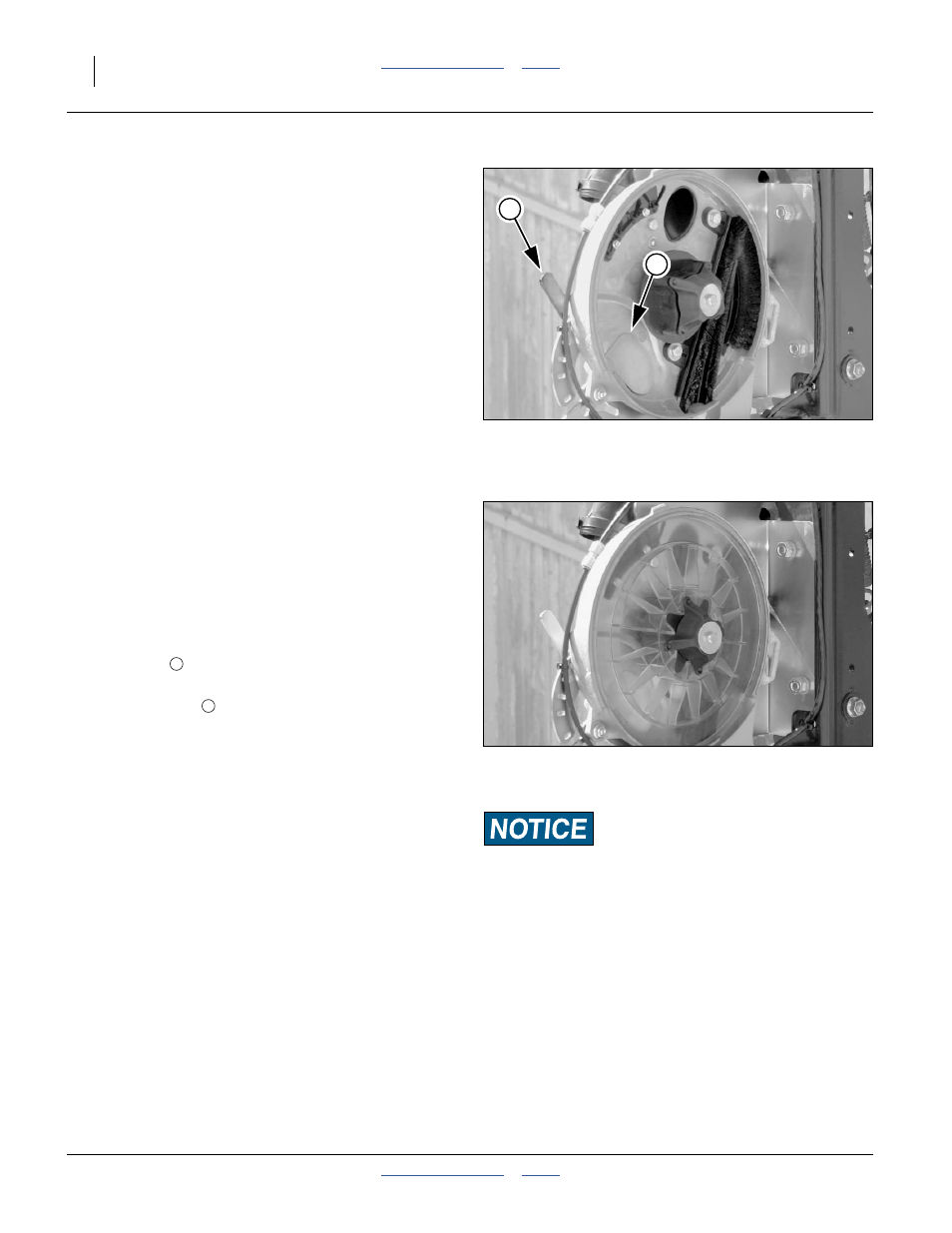

3. Install Blank Disk

Refer to Figure 109

Clean out meter. See “Meter Clean-Out” on page 102.

Remove seed disk and install blank disk. See “Air-Pro

Meter Disk Installation” on page 82.

Blank disks (part number 817-841C) are essential in row

shut-off, both to maintain consistent meter back-pressure

to meter pressurization and to prevent wear on a seed

disk.

Blank disks are engineered to simulate a seed disk with

seed in all pockets. Blanks are particularly important on

the rows with sensor lines to the pressure chamber.

Figure 108

Seed Inlet Shutter Closed

29609

2

1

Irregular Seeding Risk:

Always use a blank disk in a shut-off row. Operating with no

disk, or with a seed disk but no seed, destabilizes the regulated

airflow, particularly at rows with pressure sensor lines.

Figure 109

Shutter Closed, Blank Disk Installed

29610

2

1