01 basic troubleshooting, 02 power source problems, 01 power source problems – Tweco 200DC Inverter Arc Welding Machine User Manual

Page 55: Section 5, Basic troubleshooting -1, Power source problems -1, Weldskill 200ac/dc inverter

WELDSKILL 200AC/DC INVERTER

Manual 0-5207

5-1 POWER SOURCE PROBLEMS AND ROUTINE SERVICE REQUIREMENTS

SECTION 5:

POWER SOURCE PROBLEMS AND ROUTINE SERVICE

REQUIREMENTS

5.01 Basic Troubleshooting

!

WARNING

There are extremely dangerous voltage and power levels present inside this product. Do not attempt

to open or repair unless you are a qualified electrical tradesperson and you have had training in

power measurements and troubleshooting techniques.

If major complex subassemblies are faulty, then the Welding Power Source must be returned to an ac-

credited CIGWELD Service Provider for repair. The basic level of troubleshooting is that which can be

performed without special equipment or knowledge. Refer also to section 4 for solving welding problems.

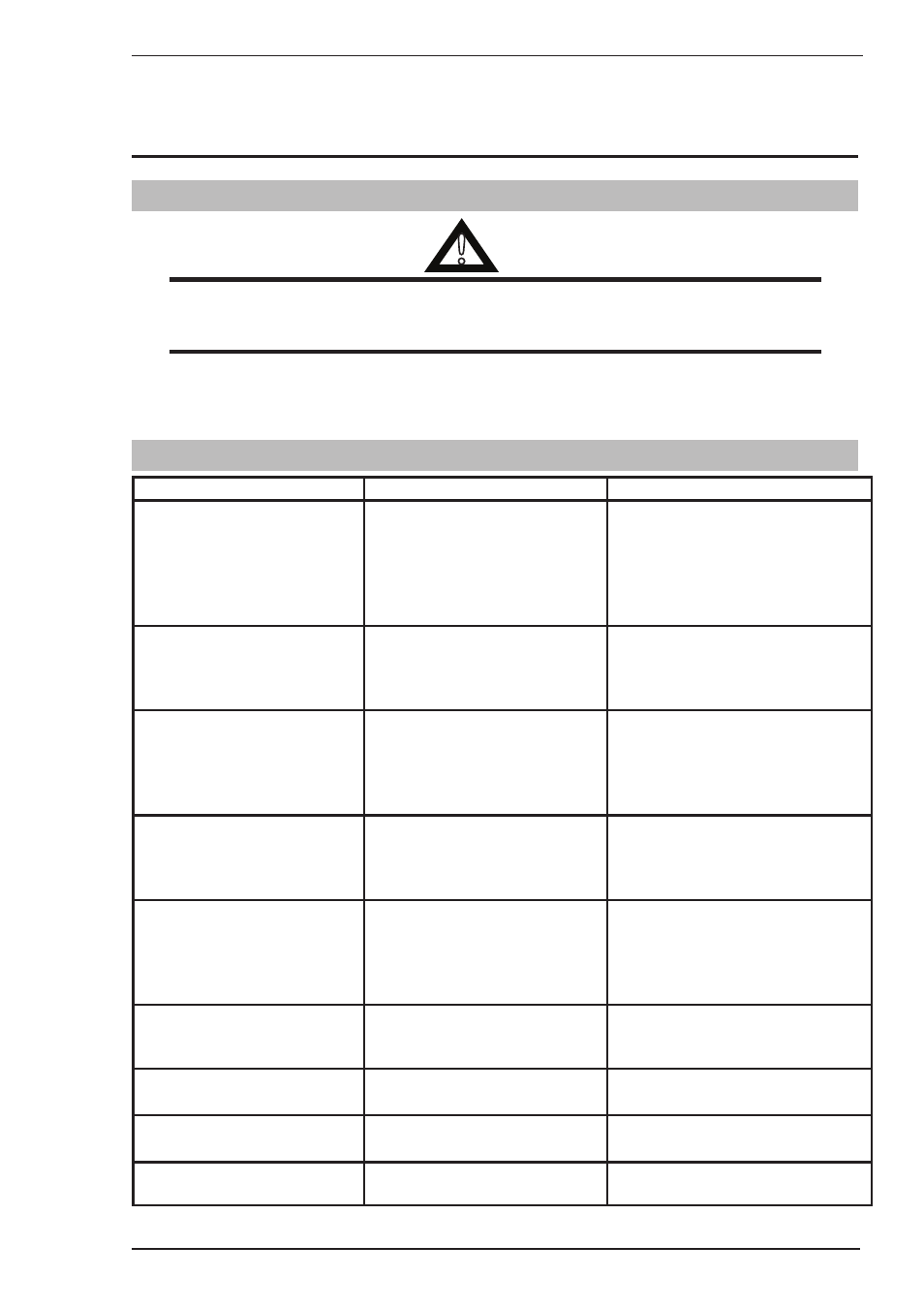

5.02 Power Source Problems

FAULT

CAUSE

REMEDY

1 Mains supply voltage is

ON, power indicator is

illuminated however unit

will not commence welding

when the torch trigger

switch is depressed.

A

B

Power source is not in the

correct mode of operation.

Faulty torch trigger.

A

B

Set the power source to the

correct mode of operation with

the process selection switch.

Repair or replace torch trigger

switch/lead.

2 Mains supply voltage is

ON. Indicator light is not lit

and welding arc cannot be

established.

A

B

Primary control fuse is blown.

Broken connection in primary

circuit.

A

B

Replace primary control fuse.

Have an Accredited CIGWELD

Service Provider check primary

circuit.

3 Fault Indicator is illuminated

and unit will not commence

welding when the torch

trigger switch is depressed.

Duty cycle of power source has

been exceeded.

Leave the power source

switched ON and allow it to

cool. Note that fault indicator

must be extinguished prior to

commencement of welding.

4 Welding output continues

when torch trigger released

A

B

Trigger mode selection is in 4T

(LATCH) mode

Torch trigger leads shorted

A

B

Change to 2T (NORMAL) mode

Repair or replace Torch / trigger

lead

5 Welding output voltage

is present when the

torch trigger switch is

depressed but arc cannot be

established.

Poor or no work lead contact.

Clean work clamp area and ensure

good electrical contact.

6 Welding output voltage is

not present when torch

trigger depressed

Faulty trigger switch / lead

Repair or replace Torch / trigger

lead

7 TIG electrode melts when

arc is struck.

TIG torch is connected to

the (+) VE terminal.

Connect the TIG torch to the (-)

VE terminal.

8 Arc flutters during TIG

welding.

Tungsten electrode is too

large for the welding current.

Select the correct size of tungsten

electrode.

9 No HF output in HF mode

HF Circuit faulty

Have an Accredited CIGWELD

Service Provider check HF circuit.

Table 5-1: Power Source Problem