Weldskill 200ac/dc inverter – Tweco 200DC Inverter Arc Welding Machine User Manual

Page 40

WELDSKILL 200AC/DC INVERTER

BASIC WELDING GUIDE

4-4

Manual 0-5207

Arc Welding Technique - A Word to Beginners

For those who have not yet done any welding, the simplest way to commence is to run beads on a piece of

scrap plate. Use mild steel plate about 6.0mm thick and a 3.2mm electrode. Clean any paint, loose scale or

grease off the plate and set it firmly on the work bench so that welding can be carried out in the downhand

position. Make sure that the work clamp is making good electrical contact with the work, either directly or

through the work table. For light gauge material, always clamp the work lead directly to the job, otherwise a

poor circuit will probably result.

The Welder

Place yourself in a comfortable position before beginning to weld. Get a seat of suitable height and do as

much work as possible sitting down. Don't hold your body tense. A taut attitude of mind and a tensed body

will soon make you feel tired. Relax and you will find that the job becomes much easier. You can add much to

your peace of mind by wearing a leather apron and gauntlets. You won't be worrying then about being burnt

or sparks setting alight to your clothes.

Place the work so that the direction of welding is across, rather than to or from, your body. The electrode

holder lead should be clear of any obstruction so that you can move your arm freely along as the electrode

burns down. If the lead is slung over your shoulder, it allows greater freedom of movement and takes a lot of

weight off your hand. Be sure the insulation on your cable and electrode holder is not faulty, otherwise you

are risking an electric shock.

Striking the Arc

Practice this on a piece of scrap plate before going on to more exacting work. You may at first experience

difficulty due to the tip of the electrode "sticking" to the work piece. This is caused by making too heavy a

contact with the work and failing to withdraw the electrode quickly enough. A low amperage will accentuate it.

This freezing-on of the tip may be overcome by scratching the electrode along the plate surface in the same

way as a match is struck. As soon as the arc is established, maintain a 1.6mm to 3.2mm gap between the

burning electrode end and the parent metal. Draw the electrode slowly along as it melts down.

Another difficulty you may meet is the tendency, after the arc is struck, to withdraw the electrode so far that

the arc is broken again. A little practice will soon remedy both of these faults.

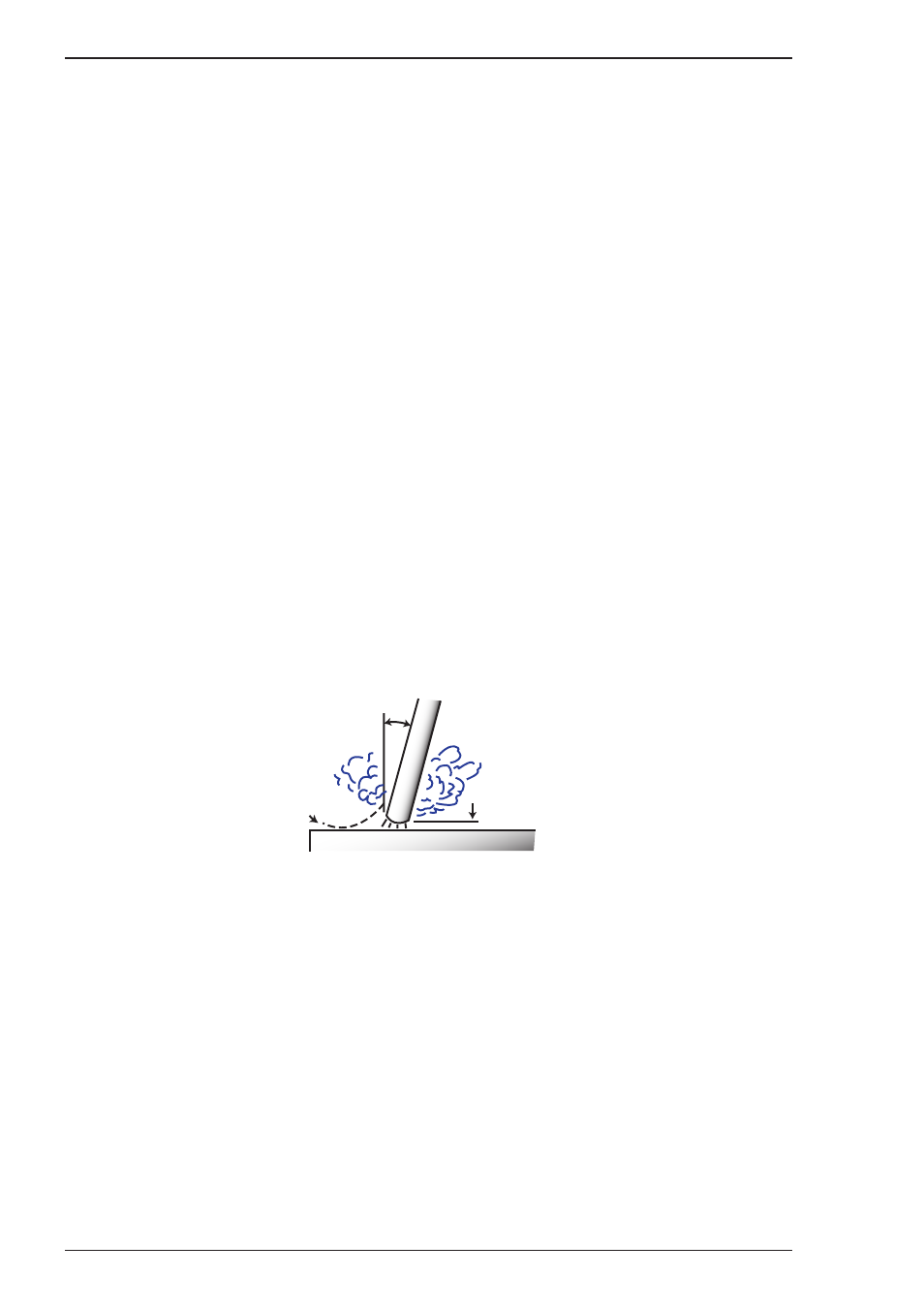

Art # A-07696_AB

20°

1.6 mm (1/16”)

Figure 4-10: Striking an Arc

Arc Length

The securing of an arc length necessary to produce a neat weld soon becomes almost automatic. You will

find that a long arc produces more heat. A very long arc produces a crackling or spluttering noise and the

weld metal comes across in large, irregular blobs. The weld bead is flattened and spatter increases. A short

arc is essential if a high quality weld is to be obtained although if it is too short there is the danger of it being

blanketed by slag and the electrode tip being solidified in. If this should happen, give the electrode a quick

twist back over the weld to detach it. Contact or "touch-weld" electrodes such as Ferrocraft 21 do not stick in

this way, and make welding much easier.

Rate of Travel

After the arc is struck, your next concern is to maintain it, and this requires moving the electrode tip towards

the molten pool at the same rate as it is melting away. At the same time, the electrode has to move along the

plate to form a bead. The electrode is directed at the weld pool at about 20º from the vertical. The rate of travel

has to be adjusted so that a well-formed bead is produced.