11 short circuit protection while welding, 12 shielding gas regulator operating instructions, Short circuit protection while welding -12 – Tweco 200DC Inverter Arc Welding Machine User Manual

Page 30: Shielding gas regulator operating instructions -12, Weldskill 200ac/dc inverter

WELDSKILL 200AC/DC INVERTER

INSTALLATION, OPERATION AND SETUP

3-12

Manual 0-5207

Post Flow

This parameter operates in TIG

modes only and is used to adjust

the post gas flow time once

the arc has extinguished. This

control is used to dramatically

reduce oxidation of the tungsten

electrode.

Volts

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

60.0

0.0 to 60.0 seconds

AC Frequency

This parameter operates in AC

TIG mode only and is used to

set the frequency for the AC weld

current.

Volts

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

150

15 to 150 Hz

Wave Balance

This parameter operates in AC

TIG mode and is used to set the

penetration to cleaning action

ratio for the AC weld current.

Generally WAVE BALANCE is set

to 50% for AC STICK welding.

The WAVE BALANCE control

changes the ratio of penetration

to cleaning action of the AC TIG

welding arc. Maximum weld

penetration is achieved when

the WAVE BALANCE control is

set to 10%. Maximum cleaning

of heavily oxidised aluminium or

magnesium alloys is achieved

when the WAVE BALANCE control

is set to 65%.

5

Volts

6

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

10 to 65%

Table 3-3

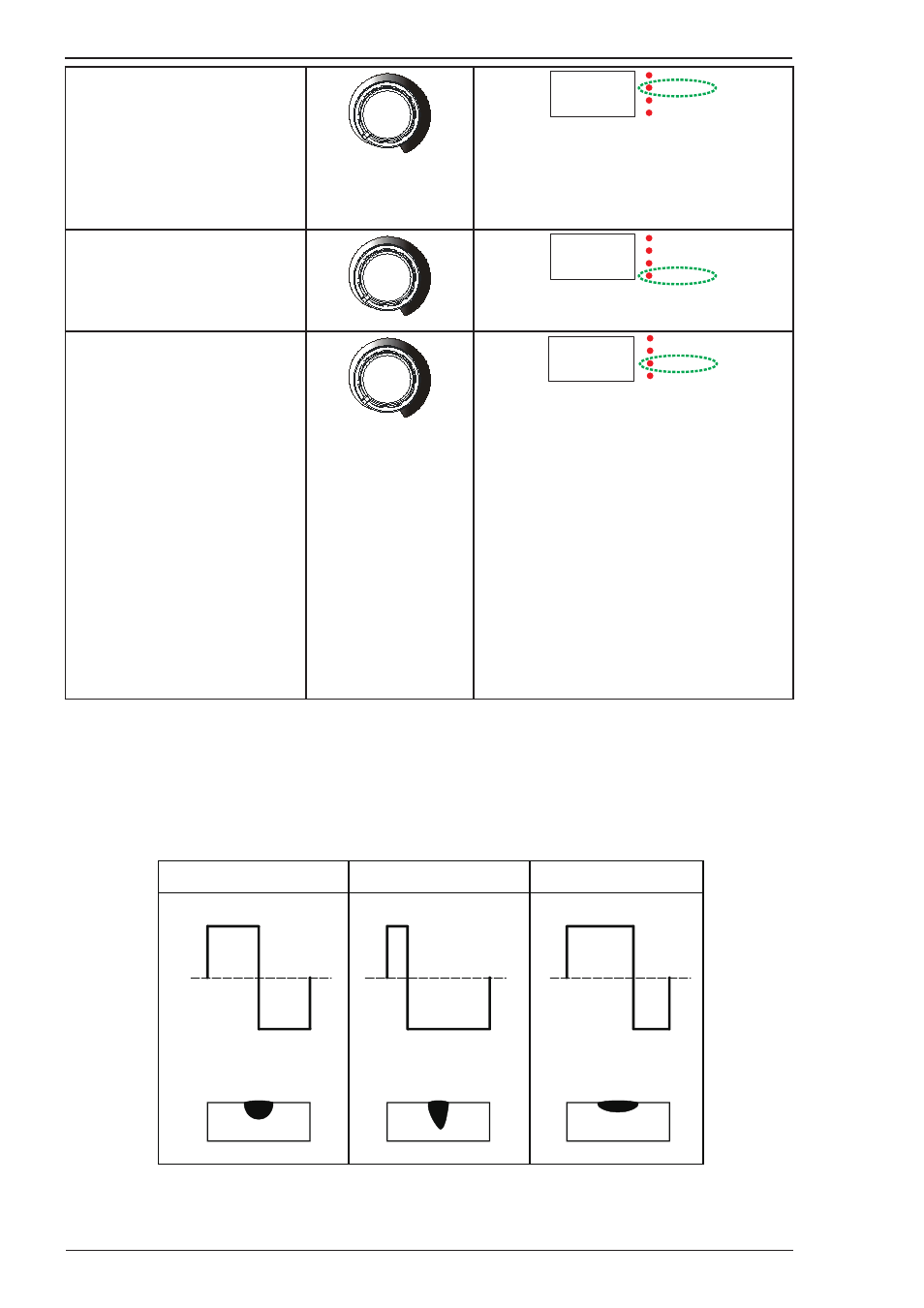

WAVE BALANCE is used for aluminium welding in AC HF TIG or AC LIFT TIG mode

It is used to set the ratio of penetration to cleaning action for the AC TIG welding arc.

Maximum weld penetration is achieved when the WAVE BALANCE is set to 10%. Maximum cleaning of heavily

oxidised aluminium or magnesium alloys is achieved when the WAVE BALANCE is set to 65%.

Maximum Penetration and

reduced cleaning

Balanced with 50% penetration

and 50% cleaning

Maximum Cleaning and

reduced penetration

10%

50%

65%

90%

50%

35%

(+)

(+)

(+)

(-)

(-)

(-)

Wave Balance = 50%

Wave Balance = 10%

Wave Balance = 65%

A-11223

Table 3-4: AC TIG Wave Balance