09 weldskill 200ac/dc - stick programming mode, Weldskill 200ac/dc - stick programming mode -8, Weldskill 200ac/dc inverter – Tweco 200DC Inverter Arc Welding Machine User Manual

Page 26: Inverter, Figure 3-5: stick programming mode

WELDSKILL 200AC/DC INVERTER

INSTALLATION, OPERATION AND SETUP

3-8

Manual 0-5207

19. Digital Voltmeter / Parameter meter

The digital volt meter is used to display the actual output voltage of the power source. It is also used to

display Parameters in Programming Mode.

Depending on the Programming Parameter selected, the status indictor adjacent to the volt meter will

illuminate to show the units of the programming parameter.

When welding, the volt meter will display actual welding voltage.

20. On / Off Switch

This Switch is located on the rear of the Power Source and turns mains power off and on.

!

WARNING

When the front digital displays are lit, the machine is connected to the Mains supply voltage and

the internal electrical components are at Mains voltage potential

21. Shielding Gas Inlet

The Shielding Gas Inlet is a 5mm nipple suitable for connection of a gas hose to a regulated Shielding Gas

Supply. The Shielding Gas inlet is located on the rear of the Power Source.

22. Cooling Fan

The WeldSkill 200AC/DC is fitted with a cooling fan that will operate continuously when the On/Off switch

on the rear panel is switched to the On position.

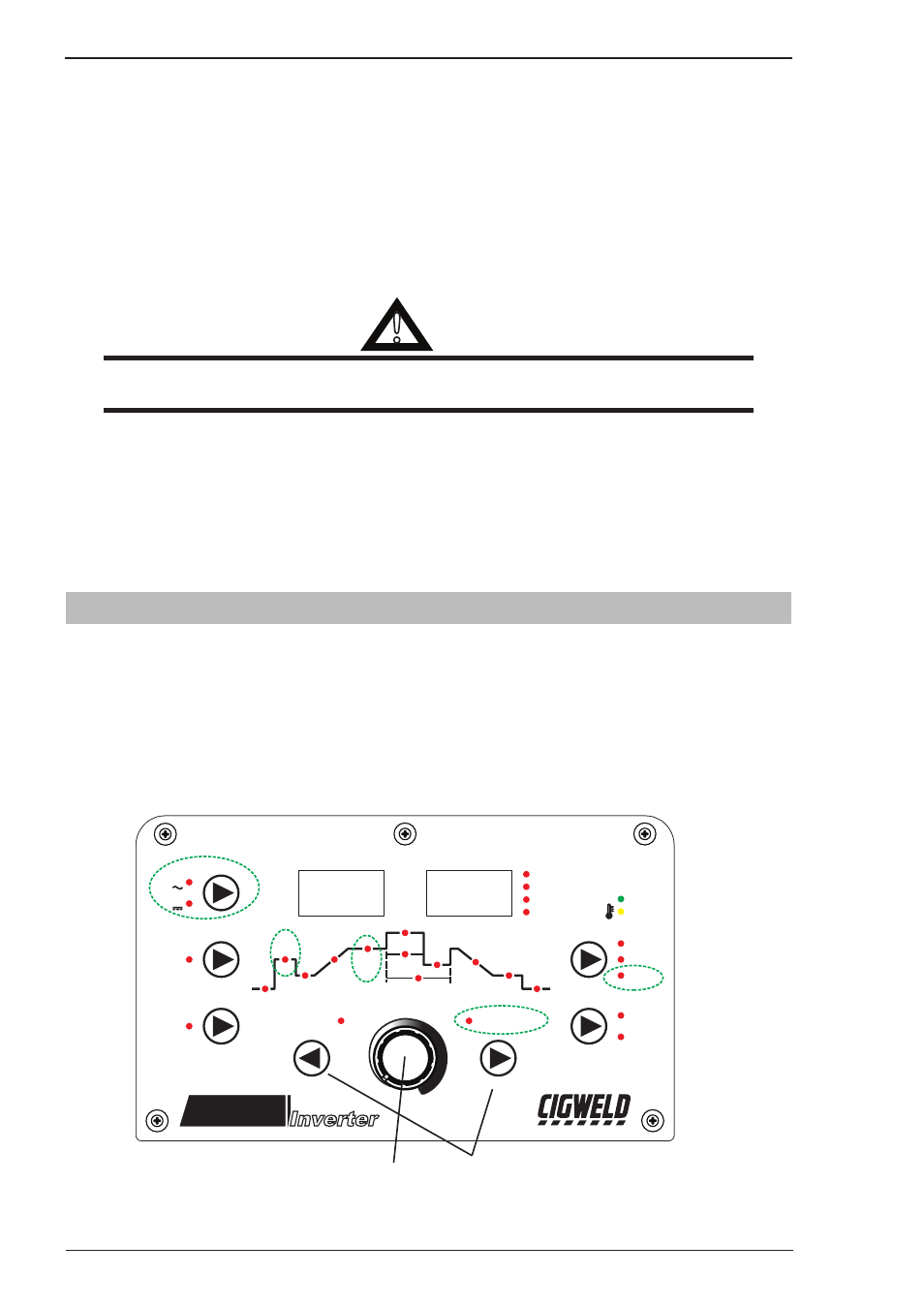

3.09 WELDSKILL 200AC/DC - STICK Programming Mode

Press the PROCESS button to select STICK mode.

Press the MODE switch to toggle between AC and DC welding output.

The Programming LED’s are always active. Press FORWARD or BACK to cycle through available programming

functions.

Use the Multi Function Control to adjust the Parameter selected.

While welding the Multi Function Control directly controls the BASE CURRENT

FAULT

POWER

Amps

Volts

FORWARD

BACK

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

AC FREQUENCY

WAVE BALANCE

(ARC FORCE)

MODE

AC

DC

PULSE

PURGE

PROCESS

TRIGGER

2T NORMAL

4T LATCH

HF TIG

LIFT TIG

STICK

Pre

Flow

Hot

Start

Initial

Current

Up

Slope

Base

Current

Peak

Current

Width

Trough

Current

Frequency

Down

Slope

Crater

Current

Post

Flow

WeldSkill

PORTABLE WELDING MACHINE

200

AC/DC

Inverter

2 0 0

1 8 . 0

Press to go forward / go back

between programming status

LED’s

Adjust programming parameter

A-11222

Figure 3-5: Stick Programming Mode