08 installing minispool (100mm diameter), Weldskill 200ac/dc inverter, Inverter – Tweco 200DC Inverter Arc Welding Machine User Manual

Page 28

WELDSKILL 200AC/DC INVERTER

INSTALLATION, OPERATION AND SETUP

3-10

Manual 0-5207

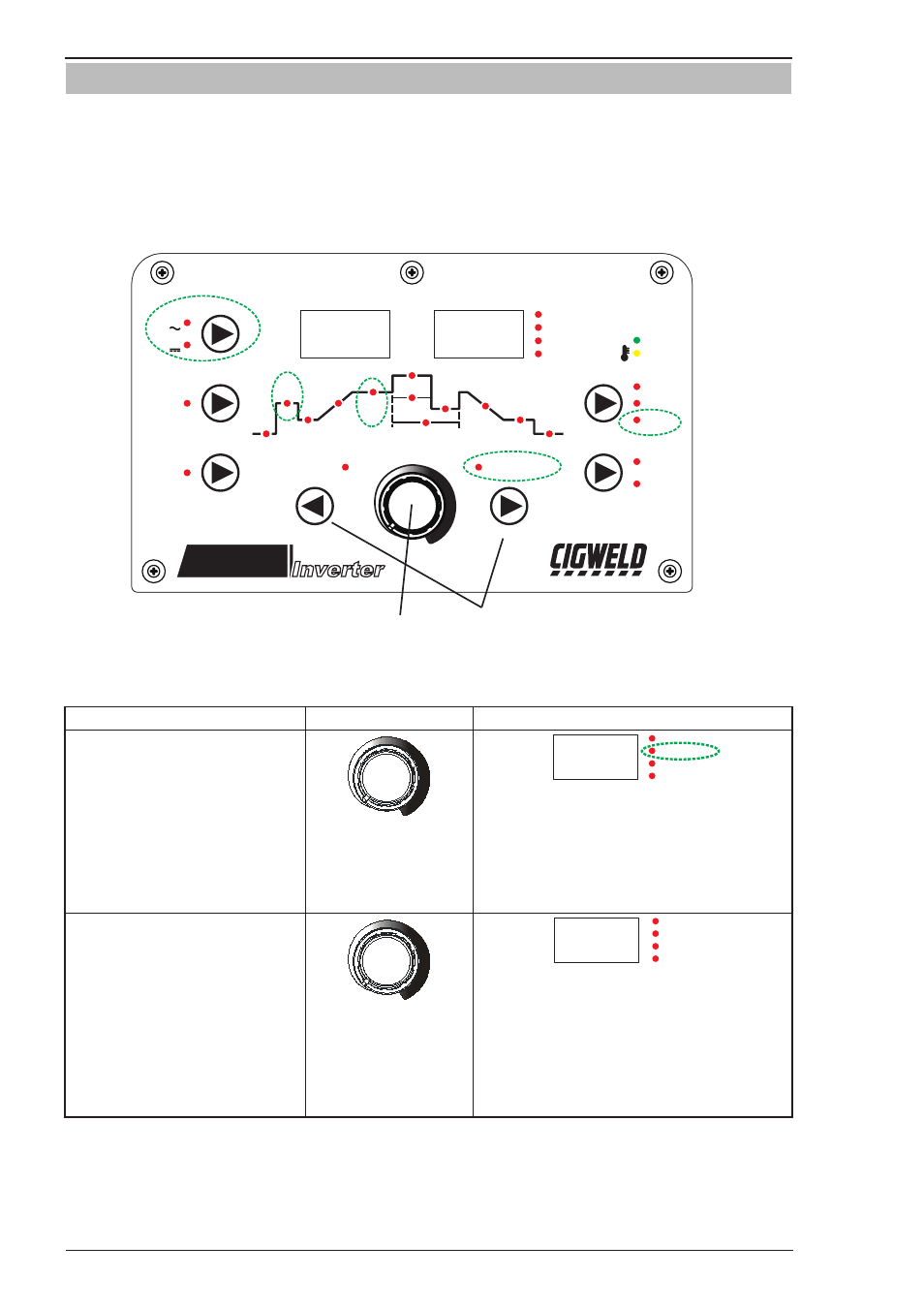

3.10 WELDSKILL 200AC/DC – LIFT TIG and HF TIG Programming Mode

Press the PROCESS button to select LIFT TIG or HF TIG mode.

Press the MODE switch to goggle between AC and DC welding output.

The Programming LED's are always active. Press FORWARD or BACK to cycle through available programming

functions.

Use the Multi Function Control to adjust the parameter selected.

FAULT

POWER

Amps

Volts

FORWARD

BACK

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

AC FREQUENCY

WAVE BALANCE

(ARC FORCE)

MODE

AC

DC

PULSE

PURGE

PROCESS

TRIGGER

2T NORMAL

4T LATCH

HF TIG

LIFT TIG

STICK

Pre

Flow

Hot

Start

Initial

Current

Up

Slope

Base

Current

Peak

Current

Width

Trough

Current

Frequency

Down

Slope

Crater

Current

Post

Flow

WeldSkill

PORTABLE WELDING MACHINE

200

AC/DC

Inverter

2 0 0

1 8 . 0

Press to go forward / go back

between programming status

LED’s

Adjust programming parameter

A-11222

Figure 3-6: LIFT TIG and HF TIG Programming Mode

Programming Parameter

Adjustment Device

Display

Pre-Flow

This parameter operates in

TIG modes only and is used to

provide gas to the weld zone

prior to striking the arc, once

the torch trigger switch has been

pressed. This control is used to

dramatically reduce weld porosity

at the start of a weld.

Volts

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

1.0

0.0 to 1.0 second

Initial Current

This parameter operates in (4T)

TIG modes only and is used to

set the start current for TIG. The

Start Current remains on until the

torch trigger switch is released

after it has been depressed.

Note: The maximum initial current

available will be limited to the set

value of the base current.

Amps

200

VOLTS

SECONDS

PERCENT (%)

FREQ (Hz)

5 to 200 Amps (DC TIG mode)

30 to 200 Amps (AC LIFT TIG mode)

10 to 200A (AC HF TIG mode)