Tweco 201 ts Thermal Arc User Manual

Page 32

THERMAL ARC 161 STL, 201 TS

OPERATION

Operation

4-2

Manual 0-5203

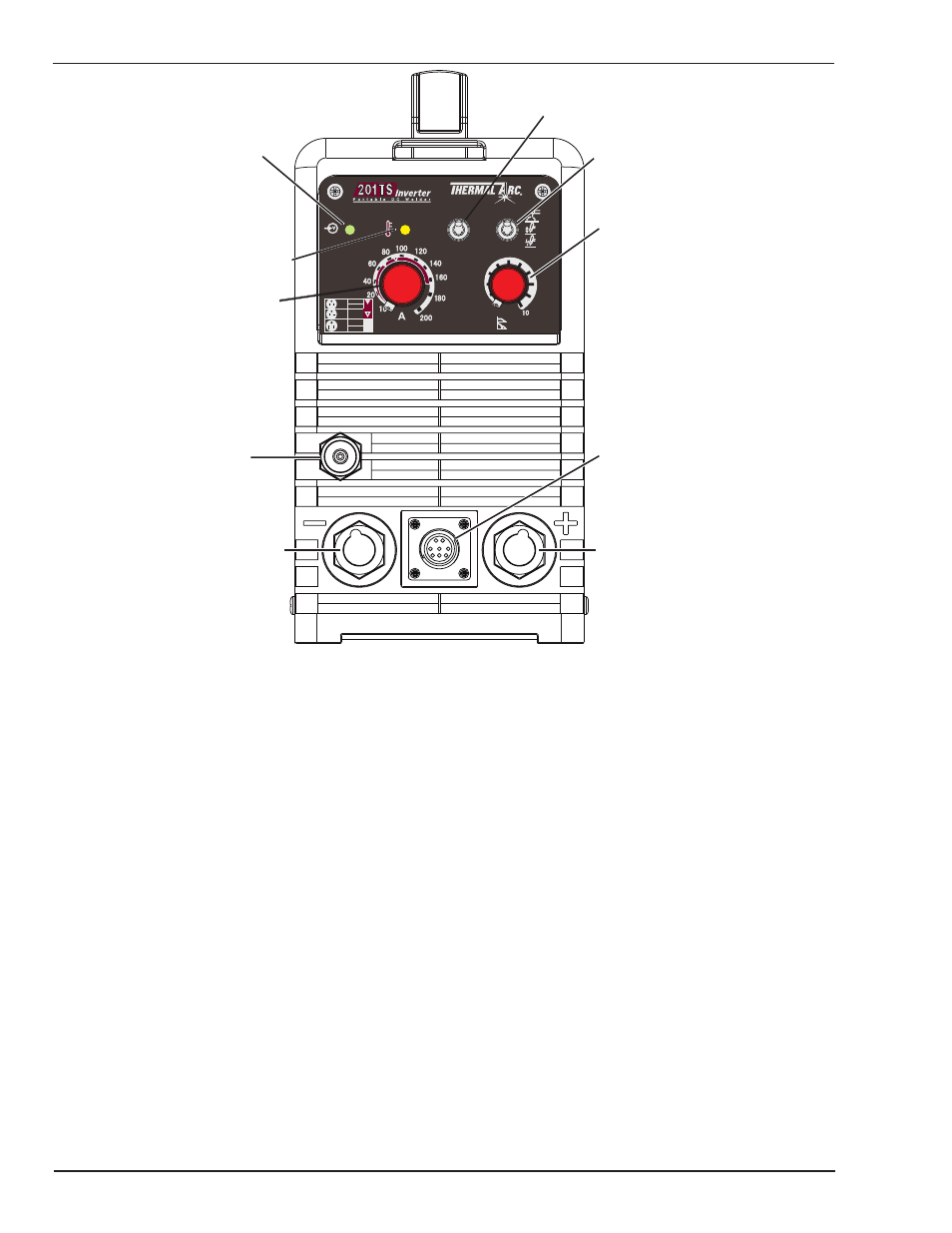

Figure 4-2: Thermal Arc 201 TS Controls

A. POWER Indicator

The POWER Indicator illuminates when the ON/OFF switch is in the ON position and the correct mains voltage is

present.

B. FAULT Indicator

If Fault indicator lights up continuously then that is an Overcurrent Condition and needs to be serviced by an Autho-

rized Thermalarc Technician.

C. TRIGGER Mode Switch (LIFT TIG Mode Only)

2T (Normal) Mode

Press the TIG Torch Trigger Switch or Foot Control and hold depressed to weld. Release the TIG Torch Trigger Switch

or Foot Control to stop welding. Down Slope operates in LIFT TIG/HF TIG (GTAW) mode only. While welding if the

TIG Torch Trigger Switch is released, the welding current ramps down to zero current over a defined period of time.

The time period is determined by the Down Slope Control Knob (F).

4T (Latch) Mode

This mode of welding is mainly used for long weld runs. The operator need only to press the TIG Torch Trigger Switch

to activate and then release the TIG Torch Trigger Switch to continue to weld, then press the TIG Torch Trigger Switch

again and release the TIG Torch Trigger Switch to stop welding. This eliminates the need for the operator to depress the

TIG Torch Trigger Switch for the complete length of the weld. The 4T mode incorporates a current slope function which

includes a fixed current up slope of 1 second and an adjustable current down slope. Current slope operates in TIG Mode

Art # A-10441

(A) Power On Indicator

(B) Fault Indicator

(E) Welding Current

Control

(G) Gas Outlet

Negative Output Terminal

Positive Output Terminal

(I) 8 Pin Control Socket

(F) Arc Force/Down

Slope Control

(D) Process Selection Switch

(C) Trigger Mode Selection Switch

32A OUTLET

STICK

TIG

230V

110V

TIG/STICK

32A OUTLET

16A OUTLET

4T

2T

8

2

4

6

0

(S)

(%)

SMAW

GTAW

15A

SMAW

20A

115V

50A

SMAW

GTAW

208/

230V

SMAW

GTAW

GTAW

PROCESS

PROCESSUS

TRIGGER

GÂCHETTE